Sodium stearate and continuous production process and production line thereof

A technology of sodium stearate and production process, applied in the field of saturated compounds, can solve the problems of easy yellowing of product color, product decomposition and deterioration, and high reaction temperature, and can reduce the production of acidic soap, reduce water consumption, and achieve high purity of finished products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

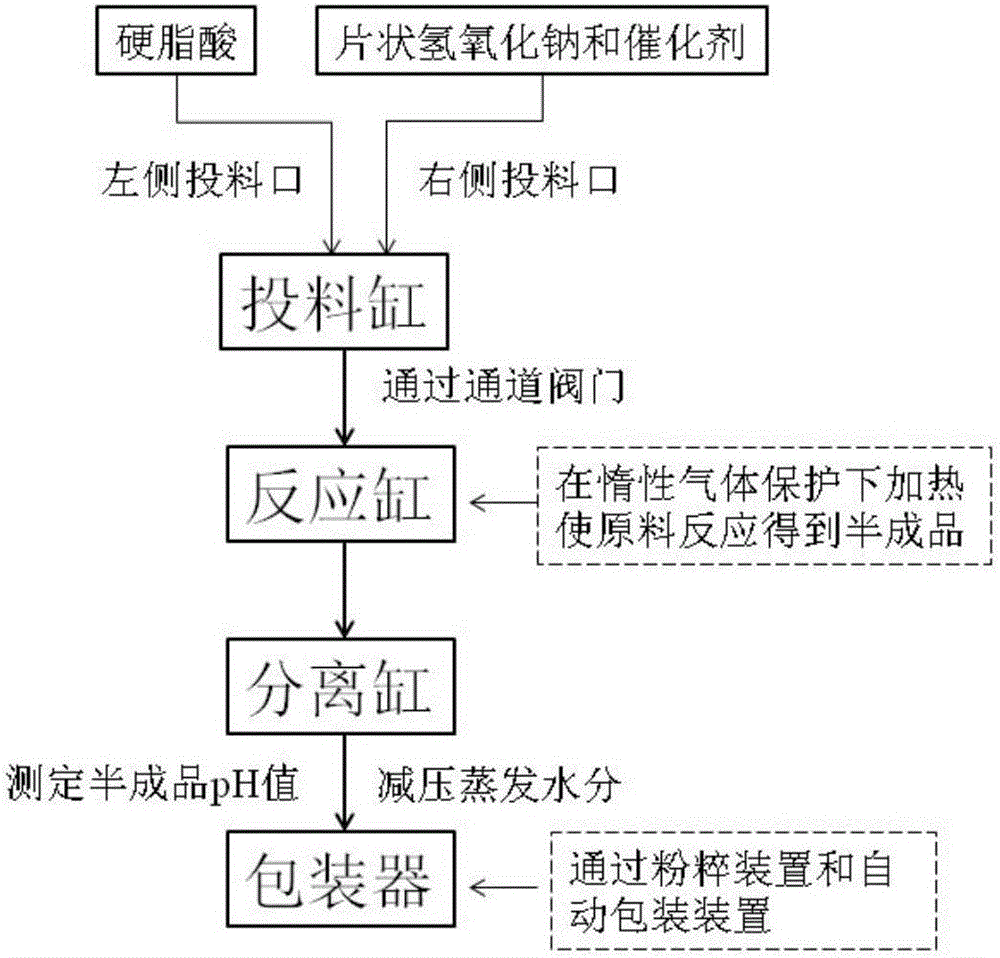

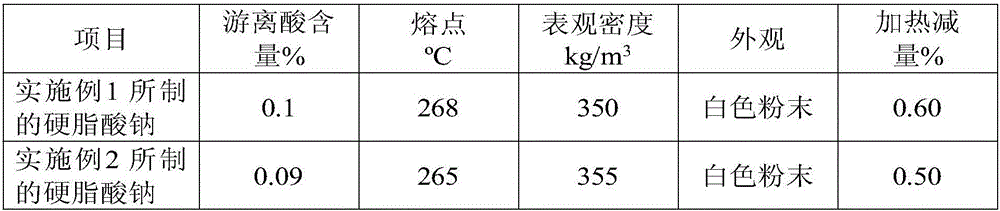

[0041] A continuous production process of sodium stearate, comprising the following steps:

[0042]Step S01, preparing raw materials for preparing sodium stearate, the raw materials include: 710 parts of stearic acid, 100 parts of sodium hydroxide flakes, and 8.1 parts of sodium carbonate; wherein the average particle size of sodium carbonate is 0.1 μm;

[0043] Step S02, feeding: close the passage valve between the feeding tank and the reaction tank, add stearic acid from the feeding port on the left side of the feeding tank, mix the flake sodium hydroxide and sodium carbonate, and add it from the feeding port on the right side of the feeding tank , close the feeding ports on both sides, rotate the feeding cylinder around the central axis for 60 minutes at a speed of 30rpm to make the materials evenly mixed, open the feeding ports on both sides, open the channel valve, and let the evenly mixed materials enter the reaction tank;

[0044] Step S03, reaction: close the upstream ...

Embodiment 2

[0048] A continuous production process of sodium stearate, comprising the following steps:

[0049] Step S01, preparing raw materials for preparing sodium stearate, the raw materials include: 710 parts of stearic acid, 105 parts of sodium hydroxide in flake form, and 48.9 parts of sodium bicarbonate; wherein the average particle size of sodium carbonate is 0.5 μm;

[0050] Step S02, feeding: close the channel valve between the feeding tank and the reaction tank, add stearic acid from the feeding port on the left side of the feeding tank, mix the flake sodium hydroxide and sodium bicarbonate, and then add stearic acid from the feeding port on the right side of the feeding tank Add, close the feeding ports on both sides, and rotate the feeding cylinder around the central axis for 90 minutes at a speed of 60rpm to make the materials evenly mixed, open the feeding ports on both sides, and open the passage valve, so that the evenly mixed materials enter the reaction tank;

[0051] ...

Embodiment 3

[0055] A continuous production process of sodium stearate, comprising the following steps:

[0056] Step S01, preparing raw materials for preparing sodium stearate, the raw materials include: 710 parts of stearic acid, 103 parts of flake sodium hydroxide, and 28.5 parts of hydrogen peroxide;

[0057] Step S02, feeding: close the passage valve between the feeding tank and the reaction tank, add stearic acid from the feeding port on the left side of the feeding tank, mix the flake sodium hydroxide and hydrogen peroxide, and then add stearic acid from the feeding port on the right side of the feeding tank Add, close the feeding ports on both sides, rotate the feeding cylinder around the central axis for 75 minutes at a speed of 45rpm, make the materials mix evenly, open the feeding ports on both sides, open the channel valve, and let the evenly mixed materials enter the reaction tank;

[0058] Step S03, reaction: close the upstream and downstream channel valves of the reaction cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com