Preparation method of ferrous glycine sulfate complex

A technology of ferrous glycinate and complexes, which is applied in the field of preparation of ferrous glycinate complexes, can solve the problems of unfavorable production and storage, large amount of crystal water, high energy consumption for product drying, and achieve less crystal water and high drying efficiency. The effect of low dry energy consumption and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

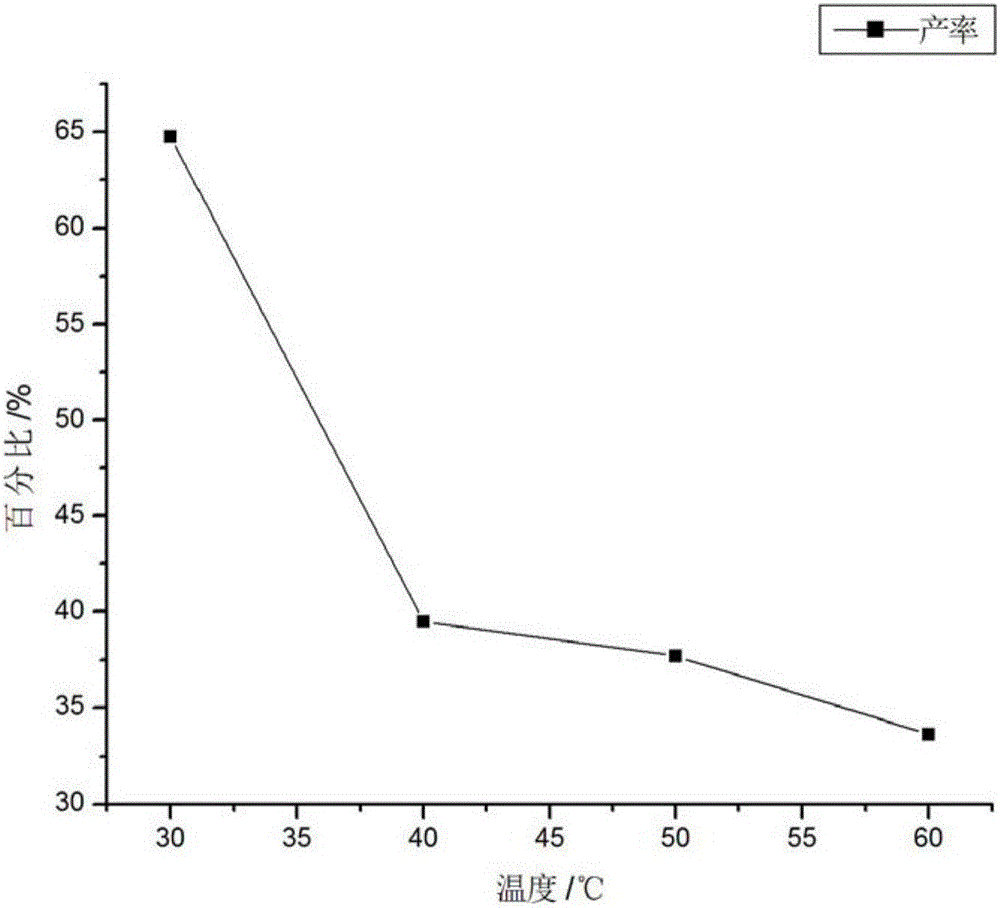

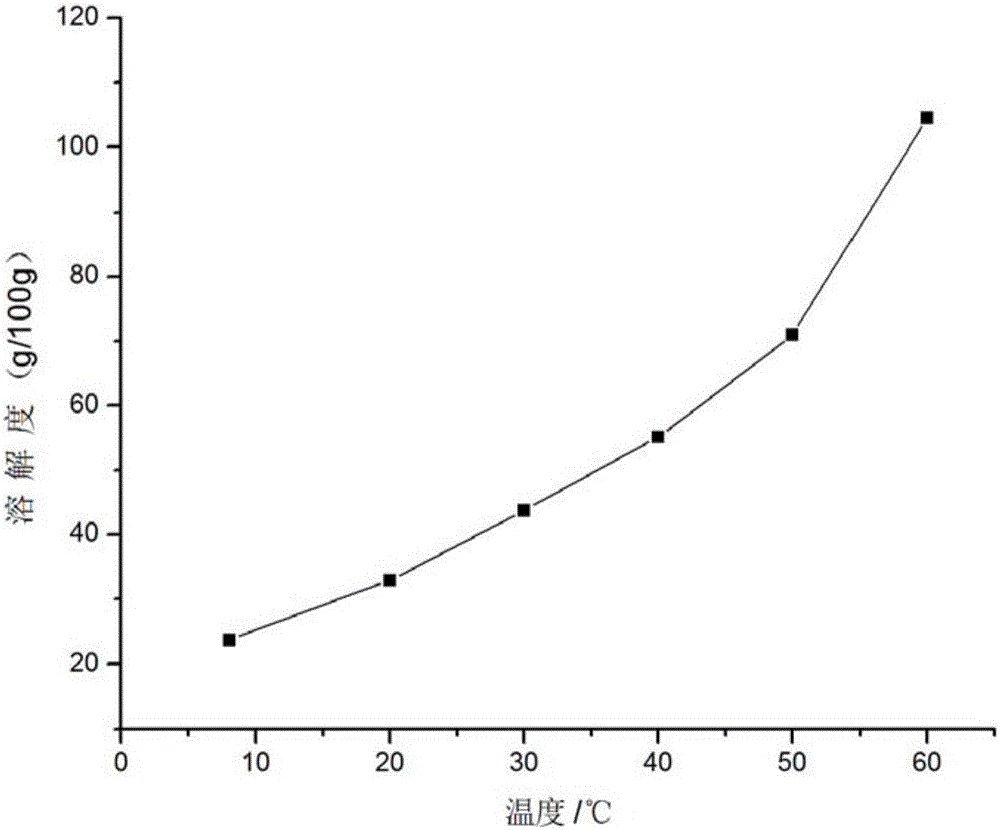

[0025] The yield of ferrous glycinate complex crystallized at normal temperature is higher, but the amount of crystal water contained in the synthesized product is more, which is not conducive to production and preservation, etc. Therefore, in order to produce higher synthetic yield, and ferrous glycine complex The amount of crystal water contained in the compound product is low, which is convenient for the storage and use of zinc glycinate. It is necessary to study the crystallization at different temperatures and different feeding concentrations, and based on the yield and the amount of crystal water, the best experiment can be obtained. Program.

[0026] 1 Experimental materials and methods

[0027] 1.1 Experimental materials and instruments

[0028] Raw materials: ferrous sulfate heptahydrate; glycine (C 2 h 5 NO 2 ); Concentrated sulfuric acid; Iron powder; Anhydrous ethanol; All reagents used were of analytical grade.

[0029] Instruments: spinner flask; azotometer;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com