A kind of preparation method and application of graphene oxide-cellulose composite hydrogel

A composite hydrogel and cellulose technology, applied in the field of material science, can solve problems such as ineffective fusion, affecting adsorption performance, and uneven performance, and achieve the effects of solving poor mechanical properties, improving adsorption performance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

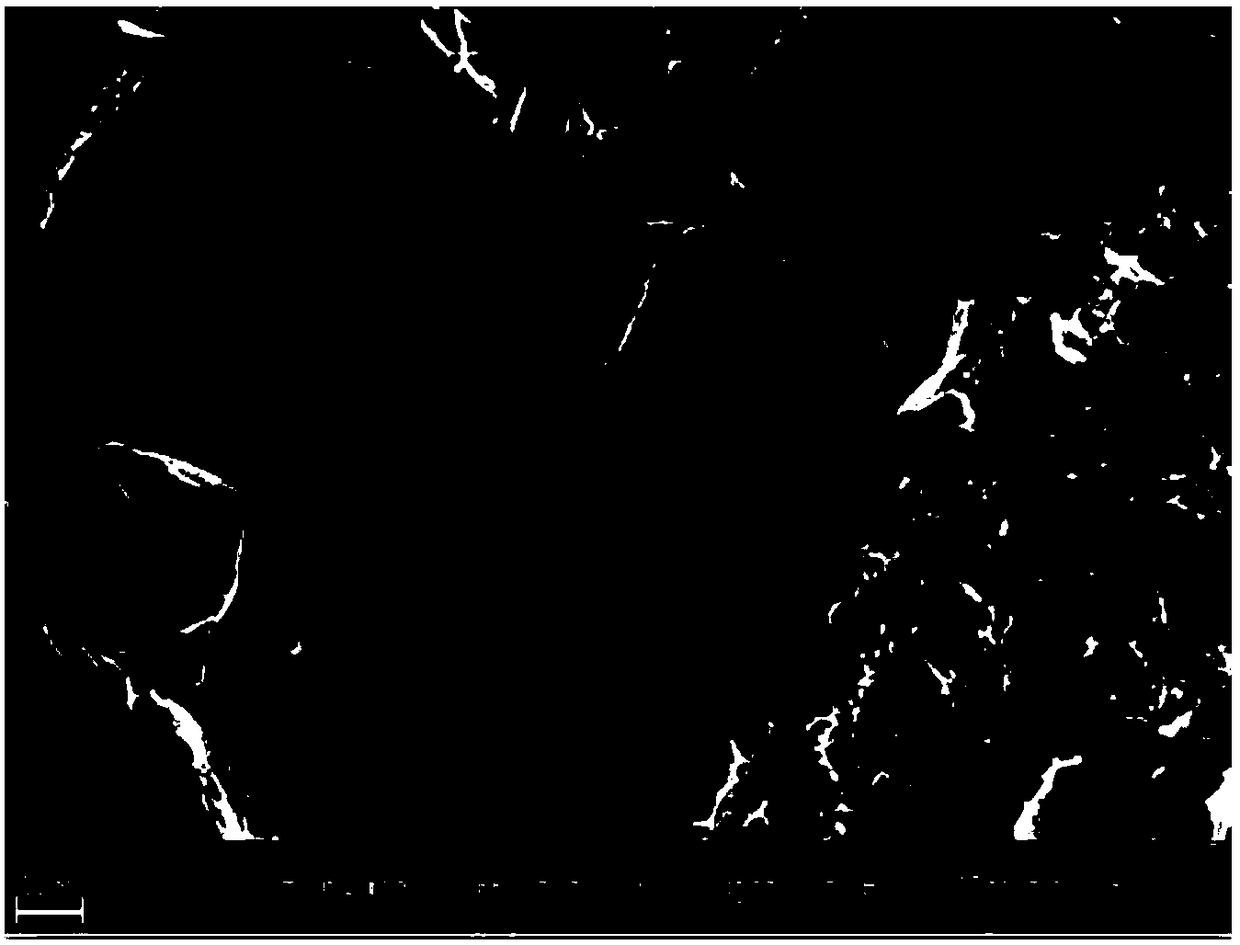

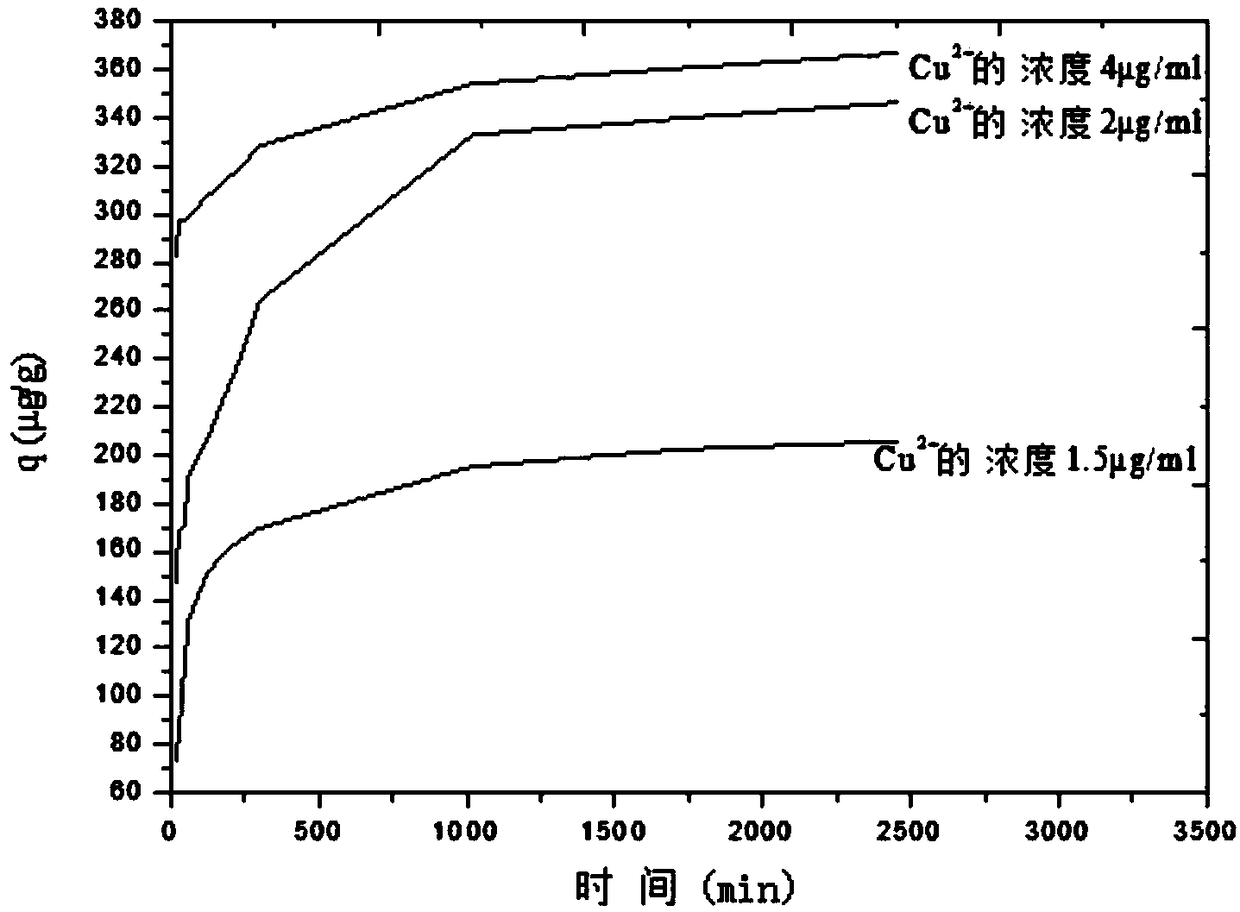

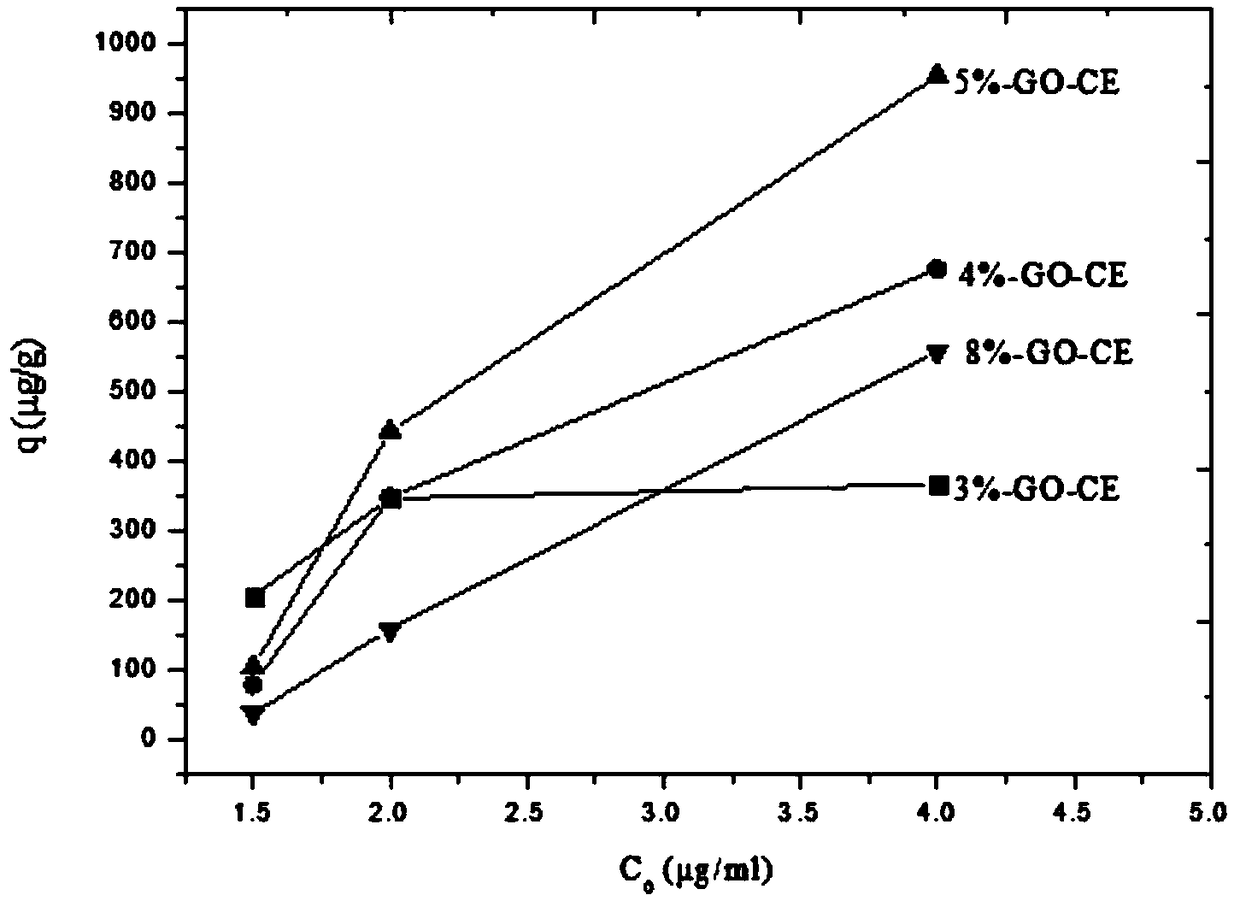

[0040] This example provides a graphene oxide-cellulose composite hydrogel and its preparation method. Described preparation method comprises the steps:

[0041] 1) After mixing 0.01g of graphene oxide and 5g of 4-methylmorpholine-N-oxide in a 100mL three-neck flask, place it in an oil bath at 110°C and heat it for 8h with stirring, and heat the volatilized 4 -Methylmorpholine-N-oxide is condensed and refluxed to obtain a black graphene oxide-4-methylmorpholine-N-oxide mixture with good dispersion;

[0042] 2) 1g of commercially available cotton pulp cellulose and 0.02g of gallic acid that are pulverized into flocculents with a pulverizer are added to 19g of 4-methylmorpholine-N-oxide solvent with a water content of 13.3wt% and stirred evenly, Swell at 70°C for 10 minutes, and then dissolve in a vacuum oven at -0.1MPa and 110°C for 24 hours to obtain a uniform and transparent amber solution, which is the cotton pulp cellulose solution. Among them, the cotton pulp cellulose so...

Embodiment 2

[0048] This example provides a graphene oxide-cellulose composite hydrogel and its preparation method. Described preparation method comprises the steps:

[0049] 1) After mixing 0.03g of graphene oxide and 5g of 4-methylmorpholine-N-oxide in a 100mL three-neck flask, place it in an oil bath at 100°C for 8 hours with stirring and heating, and heat the volatilized 4 -Methylmorpholine-N-oxide is condensed and refluxed to obtain a black graphene oxide-4-methylmorpholine-N-oxide mixture with good dispersion;

[0050] 2) Add 1g of commercially available cotton pulp cellulose and 0.02g ascorbic acid that are pulverized into flocculent form with a pulverizer into 15.6g of 4-methylmorpholine-N-oxide solvent with a water content of 12wt% and stir evenly. After swelling at 90°C for 10 minutes, put it in a vacuum drying oven at -0.2MPa and 100°C for 22 hours to dissolve, and obtain a uniform and transparent amber solution, which is the cotton pulp cellulose solution. Among them, the cott...

Embodiment 3

[0055] This example provides a graphene oxide-cellulose composite hydrogel and its preparation method. Described preparation method comprises the steps:

[0056] 1) After mixing 0.04g of graphene oxide and 5g of 4-methylmorpholine-N-oxide in a 100mL three-necked flask, place it in an oil bath at 120°C and heat it for 6h with stirring, and heat the volatilized 4 -Methylmorpholine-N-oxide is condensed and refluxed to obtain a black graphene oxide-4-methylmorpholine-N-oxide mixture with good dispersion;

[0057] 2) Add 1 g of commercially available cotton pulp cellulose and 0.02 g of gallic acid into 24 g of 4-methylmorpholine-N-oxide solvent with a water content of 12 wt % and stir evenly with a pulverizer. After swelling at 80°C for 10min, put it in a vacuum drying oven at -0.15MPa and 115°C for 26h to dissolve, and obtain a uniform and transparent amber solution, which is the cotton pulp cellulose solution. Among them, the cotton pulp cellulose solution The cellulose content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com