High-concentration quickly-dried digital ink-jet ink and preparation method thereof

A digital inkjet ink, high-concentration technology, applied in ink, household utensils, applications, etc., can solve problems such as slow drying time of the screen, affecting production speed, screen pollution, etc., to reduce screen scrapping, increase volatilization speed, and improve printing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

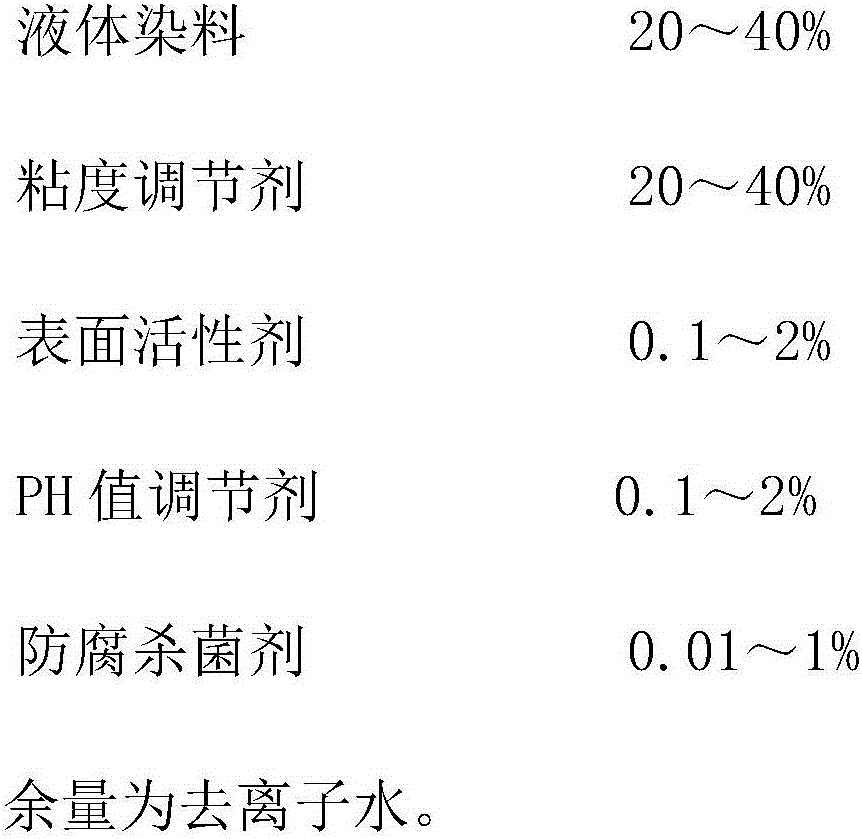

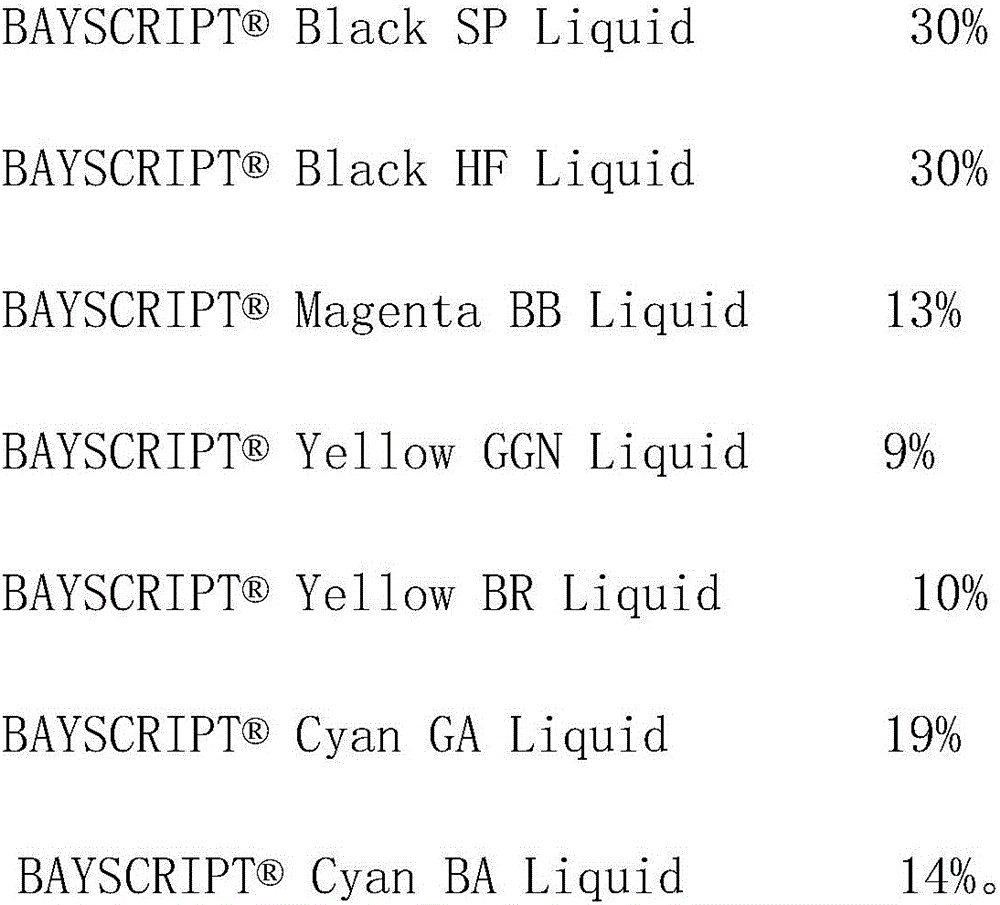

Method used

Image

Examples

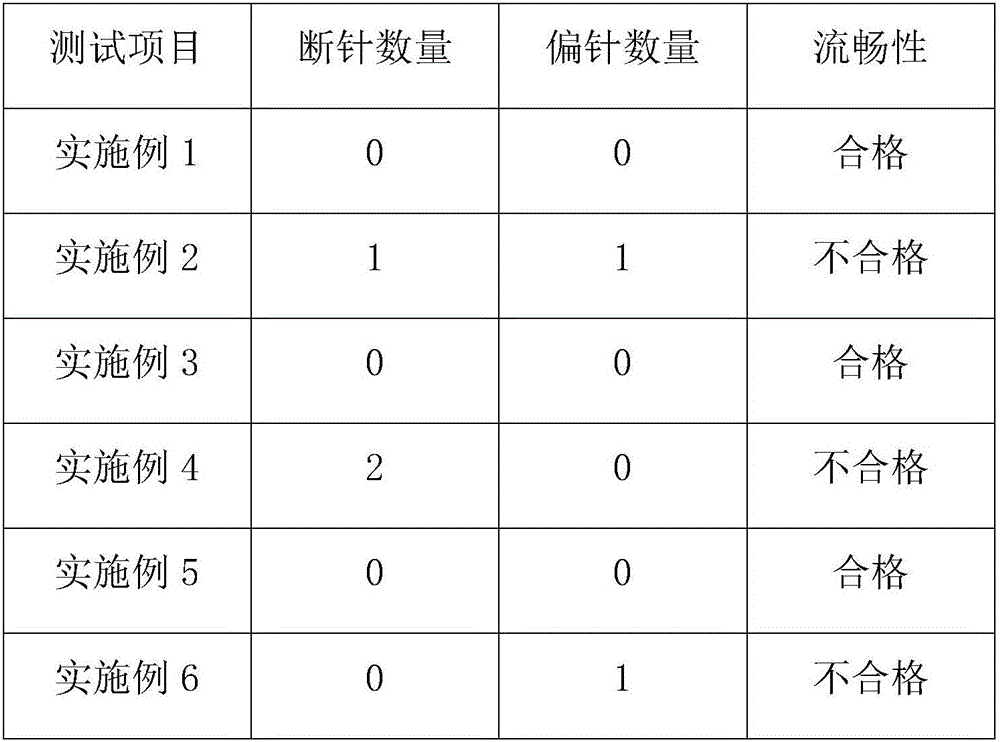

Embodiment 1

[0032] High-concentration fast-drying digital inkjet ink, including the following components by weight percentage: 35.7% deionized water, 4% isopropanol, 4% propylene glycol methyl ether, 3% diethylene glycol butyl ether, 6% diethylene glycol , N-methylpyrrolidone 2%, glycerol 13%, triethanolamine 0.1%, 1,2-benzisothiazolin-3-one 0.1%; at 35°C, add them into the mixing tank and mix for 0.5 hours; then Add the liquid dyestuff ( Black SP Liquid, manufacturer is Germany Lanxess Company), continue to mix and stir, add the tensio-active agent (surfynol TG, producer is U.S. gas company) of 0.1% weight percentage while stirring, after surfactant adds, After fully stirring for 1 hour, let it stand for 12 hours; filter through a 0.65 micron filter element, a 0.45 micron filter element and a 0.22 micron asymmetric polyethersulfone membrane filter element in turn, then filter through a vacuum filter tank, and then undergo degassing treatment to obtain a high concentration Fast drying di...

Embodiment 2

[0034] High-concentration fast-drying digital inkjet ink, including the following components by weight percentage: 35.7% deionized water, 4% isopropanol, 4% propylene glycol methyl ether, 3% diethylene glycol butyl ether, 6% diethylene glycol , N-methylpyrrolidone 2%, glycerol 13%, triethanolamine 0.1%, 1,2-benzisothiazolin-3-one 0.1%; at 35°C, add them into the mixing tank and mix for 0.5 hours; then Add the liquid dyestuff ( Black HF Liquid, manufacturer is Germany Lanxess Company), continues to mix and stir, adds the tensio-active agent (surfynol TG of weight percentage of 0.1% while stirring, and producer is U.S. gas company), after surfactant is added, After fully stirring for 1 hour, let it stand for 14 hours; filter through a 0.65 micron filter element, a 0.45 micron filter element and a 0.22 micron asymmetric polyethersulfone membrane filter element in sequence, then filter through a vacuum filter tank, and then undergo degassing treatment to obtain a high concentrati...

Embodiment 3

[0036] High-concentration quick-drying digital inkjet ink, including the following components by weight percentage: 32.7% deionized water, 4% propylene glycol methyl ether, 5% triethylene glycol butyl ether, 7% ethylene glycol, N-methylpyrrolidone 2 %, glycerol 11%, triethanolamine 0.1%, 1,2-benzisothiazolin-3-one 0.1%, at 35°C, add them into the mixing tank and mix for 0.5 hours; then add 38% by weight Liquid Dye ( Cyan BA Liquid, the producer is the German Lanxess Company), continues to mix and stir, adds the tensio-active agent (surfynol TG of the weight percentage of 0.1% while stirring, and the producer is American gas company), after the tensio-active agent is added, After fully stirring for 1 hour, let it stand for 14 hours; filter through a 0.65 micron filter element, a 0.45 micron filter element and a 0.22 micron asymmetric polyethersulfone membrane filter element in sequence, then filter through a vacuum filter tank, and then undergo degassing treatment to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com