Scratch-resisting and temperature-resisting flexible polyester-nitrile butadiene rubber composite powder paint and preparation method thereof

A technology of nitrile rubber and composite powder, which is applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of low friction coefficient of coating surface, unsatisfactory adhesion, poor peeling resistance, etc., and achieve improvement Comprehensive performance, improved surface performance, fast curing and film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A scratch-resistant and temperature-resistant flexible polyester nitrile rubber composite powder coating, the powder coating is made of the following raw materials in parts by weight: polyester resin chip 60, liquid nitrile rubber 10, ultrafine polytetrafluoroethylene powder 5 , hydroxyalkylamide 3, natural rubber latex 5, pigment 5, zinc stearate 1, silica airgel particles 5, silane coupling agent kh560 0.4, vulcanizing agent PDM 0.1.

[0012] The preparation of this embodiment powder coating comprises the following steps:

[0013] (1) Mix, grind and disperse the silica airgel particles and the silane coupling agent kh560 for 20 minutes before use;

[0014] (2) Put the material obtained in step (1) into a high-speed mixer together with other remaining raw materials to stir and mix evenly, then send the material into a twin-screw extruder, extrude and granulate at 105°C, cool, It can be obtained after crushing and sieving.

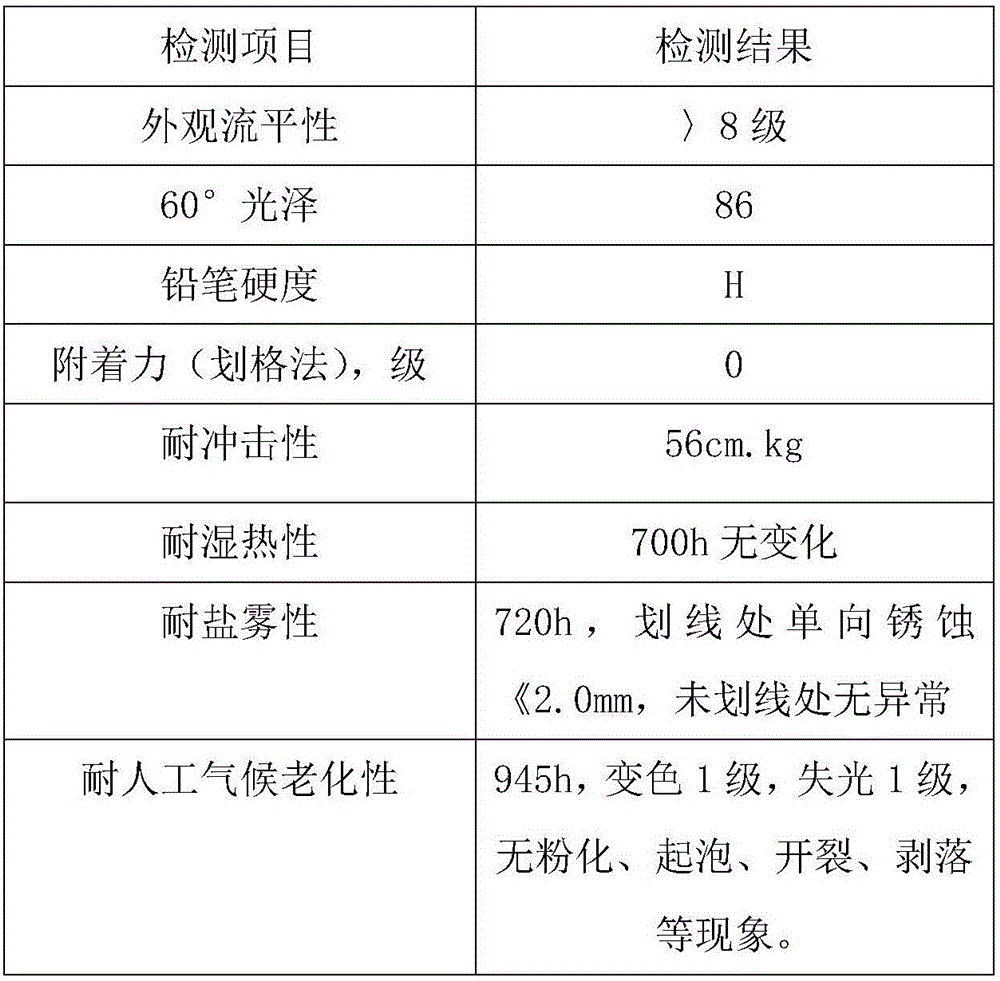

[0015] The prepared powder coating was pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com