Plant-fiber wall surface coating with antifungal and mould-proof functions

A plant fiber, antibacterial and antifungal technology, which is applied in cellulose coatings, antifouling/underwater coatings, lignin coatings, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

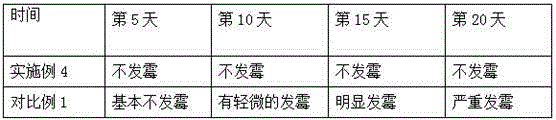

Examples

Embodiment 1

[0027] Embodiment 1. Wood fiber wall covering

[0028] It is made of 70wt% wood fiber, 30wt% water-soluble vegetable glue and a silver-based inorganic antibacterial agent whose mass fraction is 0.1wt% of the total mass of wall covering coating; wherein the silver-based inorganic antibacterial agent is made of silver nitrate, phosphate, zinc oxide according to Made by mixing in a ratio of 0.5:8:1 by weight.

[0029] Its preparation method is as follows:

[0030] (1) Weaving wood fiber into a single-ply yarn with a diameter of 3mm, mixing the single-ply yarn with 0.05wt% silver-based inorganic antibacterial agent, dyeing and cutting into a fiber segment with a length of 25mm; Cut the fiber segment with a length of 10mm and set it aside;

[0031] (2) Another 0.05wt% silver-based inorganic antibacterial agent and water-soluble vegetable glue were mixed and stirred by centrifugal type for 20 minutes to obtain mixed rubber powder;

[0032] (3) Mix the fiber segment obtained in st...

Embodiment 2

[0034] Embodiment 2. Cotton fiber wall covering

[0035] It is made from 60wt% cotton fiber, 40wt% water-soluble vegetable glue and a silver-based inorganic antibacterial agent whose mass fraction is 0.6wt% of the total mass of wall covering coating; wherein the silver-based inorganic antibacterial agent is made of silver nitrate, phosphate, zinc oxide according to Made by mixing in a ratio of 0.2:8.5:1 by weight.

[0036] Its preparation method is as follows:

[0037] (1) Spin cotton fiber into a single-ply yarn with a diameter of 1.5mm, mix the single-ply yarn with 0.2wt% silver-based inorganic antibacterial agent, dye and cut it into a fiber section with a length of 15mm; Cut the fiber segment with a length of 5mm transversely and set it aside;

[0038] (2) Another 0.4wt% silver-based inorganic antibacterial agent and water-soluble vegetable glue were mixed and stirred for 30 minutes by centrifugal type to obtain mixed rubber powder;

[0039] (3) Mix the fiber segment ob...

Embodiment 3

[0041] Embodiment 3. Bamboo fiber wall covering

[0042] It is made from 85wt% bamboo fiber, 15wt% water-soluble vegetable glue and a silver-based inorganic antibacterial agent whose mass fraction is 1.0wt% of the total mass of wall covering coating; wherein the silver-based inorganic antibacterial agent is made of silver nitrate, phosphate, zinc oxide according to Made by mixing in a ratio of 0.1:9:1 by weight.

[0043] Its preparation method is as follows:

[0044] (1) The bamboo fiber is woven into a single-ply yarn with a diameter of 2.5mm, and after the single-ply yarn is mixed with 0.5wt% silver-based inorganic antibacterial agent, it is dyed and cut into a fiber section with a length of 5mm; and the fiber section is Cut the fiber section with a length of 3mm transversely and set aside;

[0045] (2) Another 0.5wt% silver-based inorganic antibacterial agent and water-soluble vegetable glue were mixed and stirred for 25 minutes by centrifugal type to obtain mixed rubber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com