A kind of preparation technology of 6 series aluminum alloy and its pre-stretched plate

An aluminum alloy and pre-stretching technology, which is applied in the field of preparation technology of 6-series aluminum alloy and its pre-stretched sheet, can solve the problem that the second phase is not easy to fully and uniformly precipitate, the grain size grows abnormally, and the second phase is not easy Content control and other issues to achieve the effect of optimizing pass reduction rate, reducing component segregation, and controlling grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

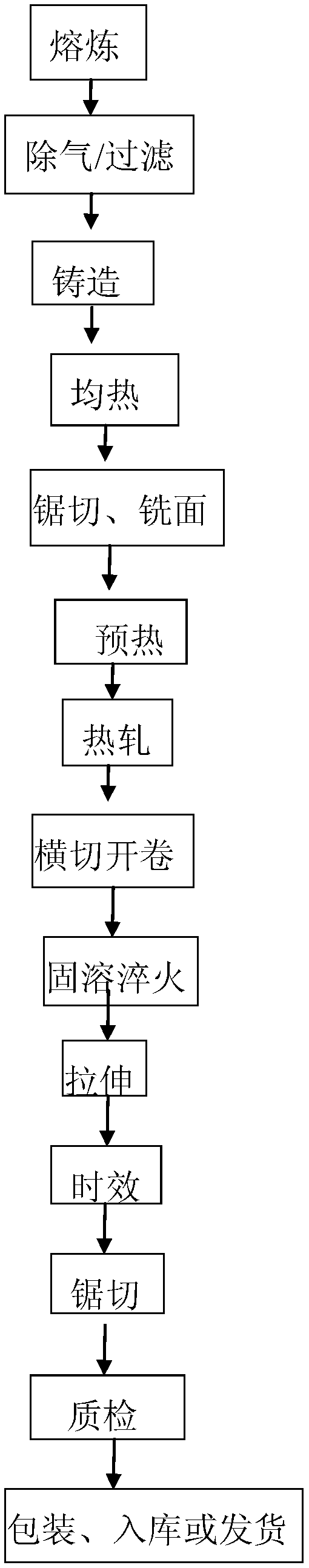

[0034] A preparation process for a 6-series aluminum alloy pre-stretched plate, the operation steps are as follows:

[0035] (1) The 6-series aluminum alloy is prepared, and its composition according to weight percentage is: Mg: 1.22%, Mn: 0.15%, Si: 0.72%, Cr: 0.27%, Zr: 0.11%, Cu: 0.26%, Fe: 0.25 %, Zn: 0.19%, Ti: 0.09%, others are Al and some unavoidable impurity elements, and then after degassing and filtering, casting, soaking treatment, and preheating are carried out in sequence, that is, casting into a flat ingot with a thickness of 550mm ;Then the slab is subjected to soaking treatment at a temperature of 515°C, the heating rate is 60°C / h, and after reaching the specified temperature, it is kept for 19h, cooled to room temperature, and the head and tail of the obtained slab are cut off and peeled to obtain the thickness For flat ingots of 525-535mm, keep the temperature at 465°C and preheat for 13.5h;

[0036] (2) Hot-roll the 6-series aluminum alloy flat ingot obtain...

Embodiment 2

[0044] A preparation process for a 6-series aluminum alloy pre-stretched plate, the operation steps are as follows:

[0045] (1) The 6 series aluminum alloy is prepared, and its composition according to weight percentage is: Mg: 0.9%, Mn: 0.08%, Si: 0.52%, Cr: 0.18%, Zr: 0.005%, Cu: 0.05%, Fe: 0.32 %, Zn: 0.25%, Ti: 0.08%, others are Al and some unavoidable impurity elements, and then after degassing and filtering, casting, soaking treatment, and preheating are carried out in turn, that is, casting into a flat ingot with a thickness of 400mm Then, the slab is subjected to soaking treatment at a temperature of 460°C, the heating rate is 40°C / h, and after reaching the specified temperature, it is kept for 30 hours and cooled to room temperature. For flat ingots of 380-390mm, keep the temperature at 420°C and preheat for 25 hours;

[0046] (2) Hot-roll the 6-series aluminum alloy flat ingot obtained after preheating in step (1), and roll it to a slab with a finished thickness of...

Embodiment 3

[0051] A preparation process for a 6-series aluminum alloy pre-stretched plate, the operation steps are as follows:

[0052] (1) The 6 series aluminum alloy is prepared, and its composition according to weight percentage is: Mg: 1.3%, Mn: 0.25%, Si: 0.9%, Cr: 0.32%, Zr: 0.06%, Cu: 0.35%, Fe: 0.25 %, Zn: 0.19%, Ti: 0.1%, others are Al and some unavoidable impurity elements, and then after degassing and filtering, casting, soaking treatment, and preheating are carried out in sequence, that is, casting into a flat ingot with a thickness of 700mm Then, the slab is subjected to soaking treatment at a temperature of 570°C, the heating rate is 80°C / h, and after reaching the specified temperature, it is kept for 8 hours, and cooled to room temperature. For flat ingots of 680-690mm, keep the temperature at 510°C and preheat for 2 hours;

[0053] (2) Hot-roll the 6-series aluminum alloy flat ingot obtained after preheating in step (1), and roll it to a slab with a finished thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com