Carbon fiber surface quick composite reinforcing treatment method

A technology of strengthening treatment and carbon fiber, which is applied in the direction of fiber treatment, carbon fiber, physical treatment, etc., can solve problems such as not being able to deal with, and achieve the effects of avoiding damage, improving production speed and productivity, and meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

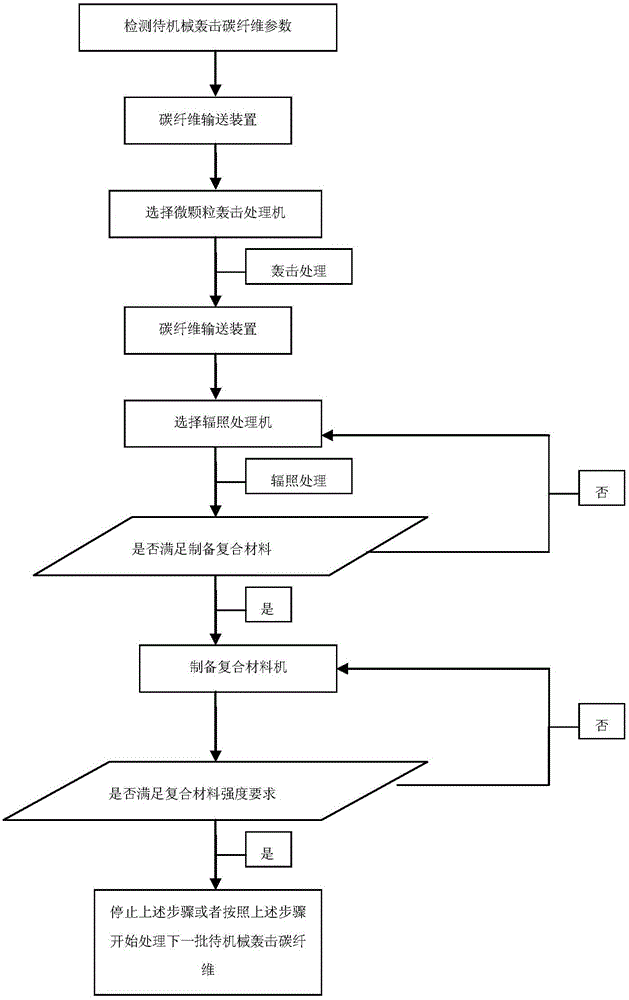

[0027] Attached below figure 1 The specific steps of the rapid composite strengthening treatment method of the carbon fiber surface of the present invention are described in detail.

[0028] A method for rapid composite strengthening treatment of carbon fiber surface and preparation of composite material, the method includes the following steps:

[0029] 1) Test carbon fiber parameters: test the specific parameter values of the carbon fiber to be processed, the parameter values include tensile strength value and elastic modulus; there are no obvious surface defects, tensile strength>70MPa, modulus>200GPa, fiber diameter is uniform And the relative error of the same fiber diameter is <5%;

[0030] 2) Select the type of microparticle bombardment processor: select a microparticle bombardment processor suitable for mechanical bombardment of the carbon fiber according to the above-mentioned parameter values of the carbon fiber detected in the previous step. The standard for selecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com