Self-adaptive stress energy-absorbing tray

A self-adaptive, tray-based technology, applied in mining equipment, earth cube drilling, bolt installation, etc., can solve problems such as difficulty in trench processing, loose surrounding rock, failure of anchoring system, etc., and achieves a simple, safe and reliable structure, which is conducive to recycling , The effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

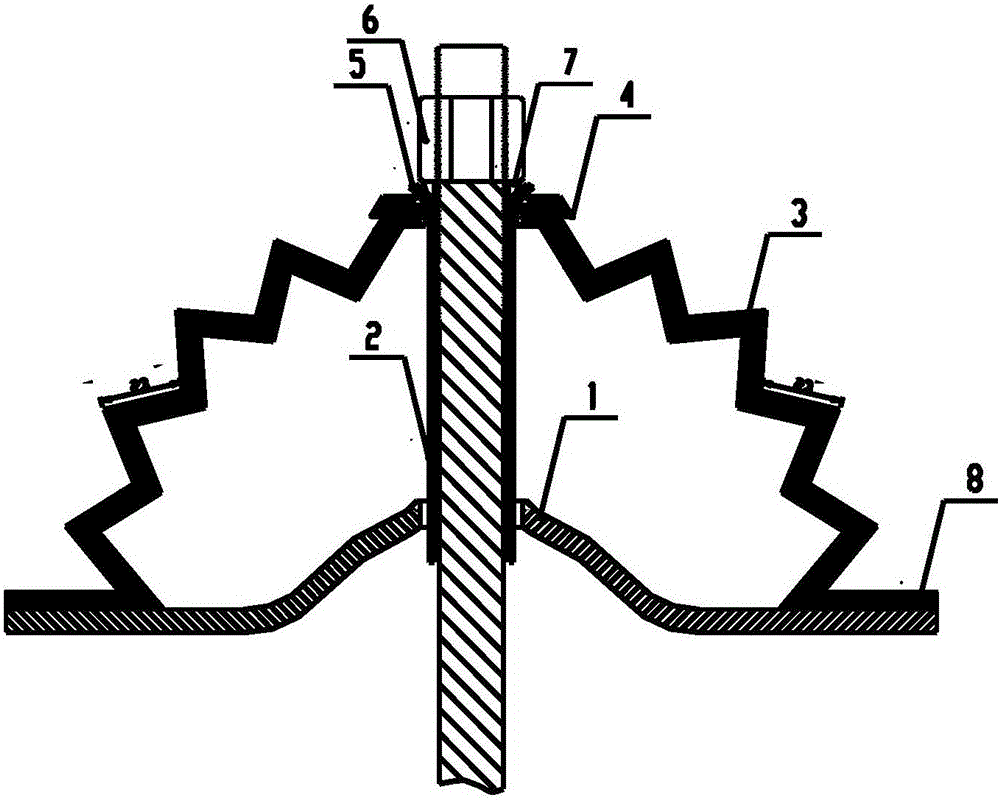

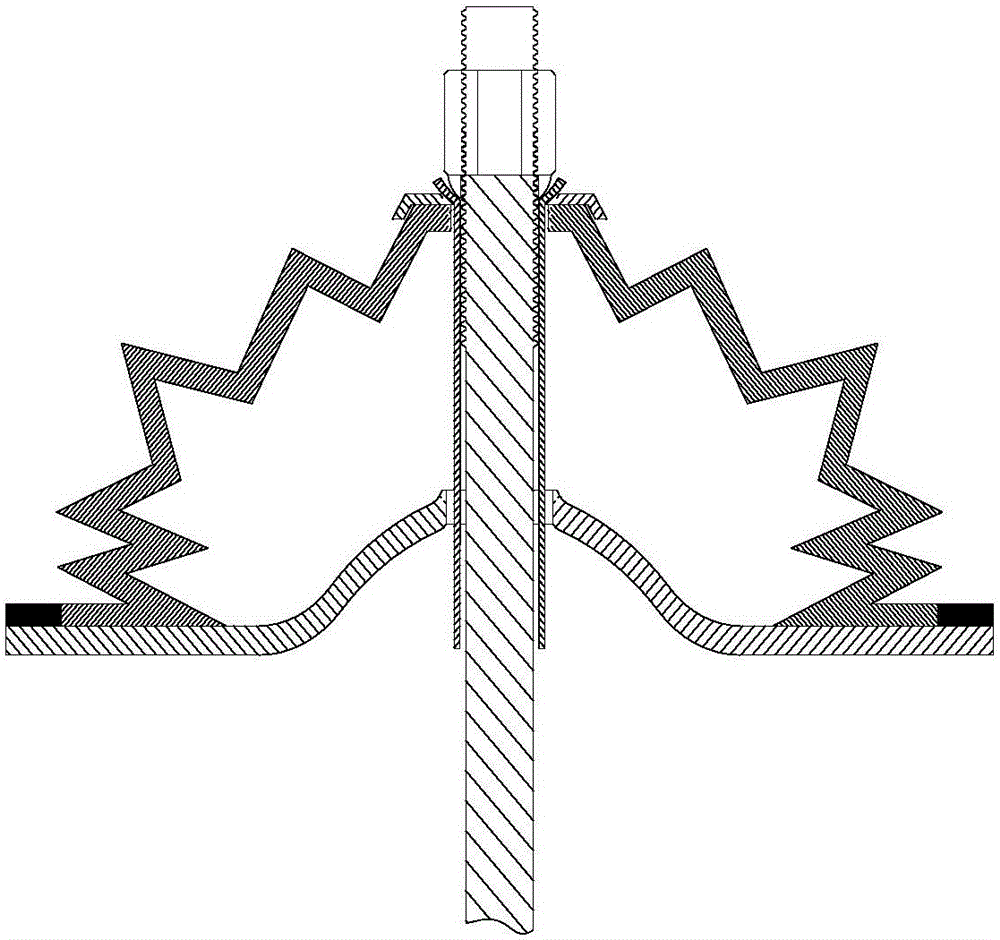

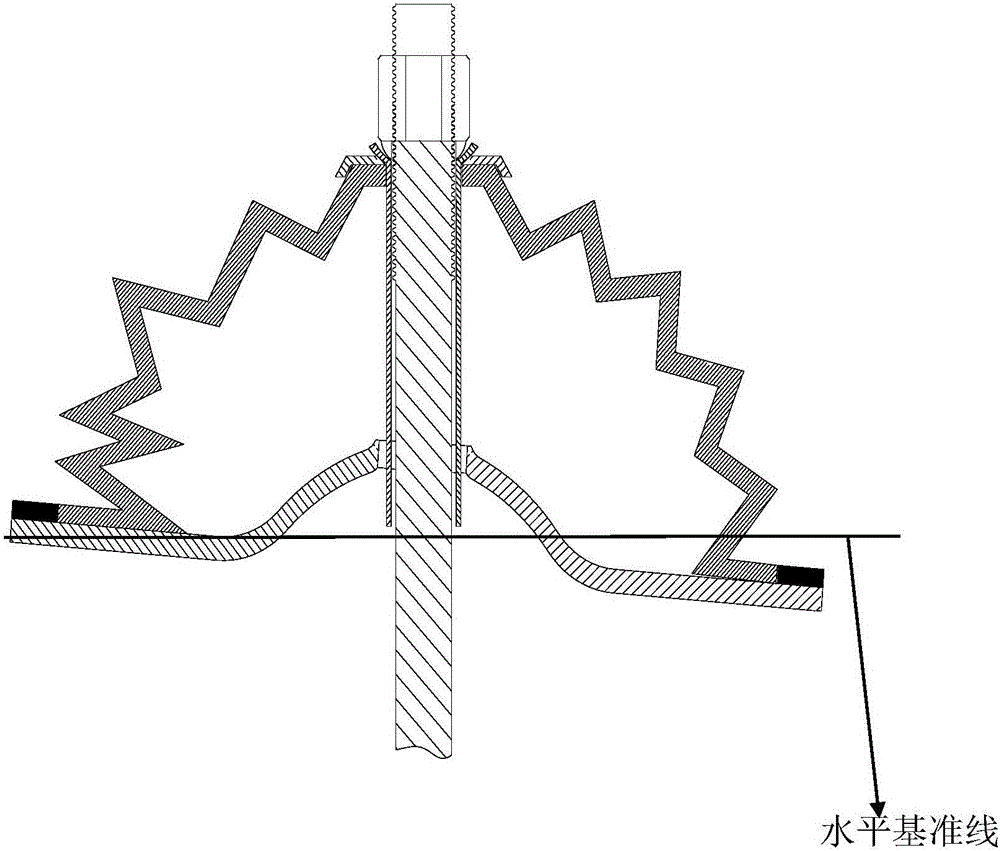

[0021] refer to figure 1 , the purpose of the present invention is to provide an adaptive force-absorbing tray, including a dish-shaped tray 1, the butterfly-shaped tray body 1 gradually forms a convex surface from the horizontal transition on both sides; the top of the dish-shaped tray 1 is a wall from the lower end to the A cone-like energy-absorbing box 3 with plastic hinges that gradually changes at the upper end. The wall thickness of the cone-like energy-absorbing box 3 is 3mm to 5mm, and the length of each wall is 20mm to 28mm. Hinge pattern, the cone-like energy-absorbing box 3 and the center of the disc-shaped tray 1 form an anchor hole, and inside the anchor hole is a bending-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com