Method for igniting natural gas by polyoxymethylene dimethyl ethers and application

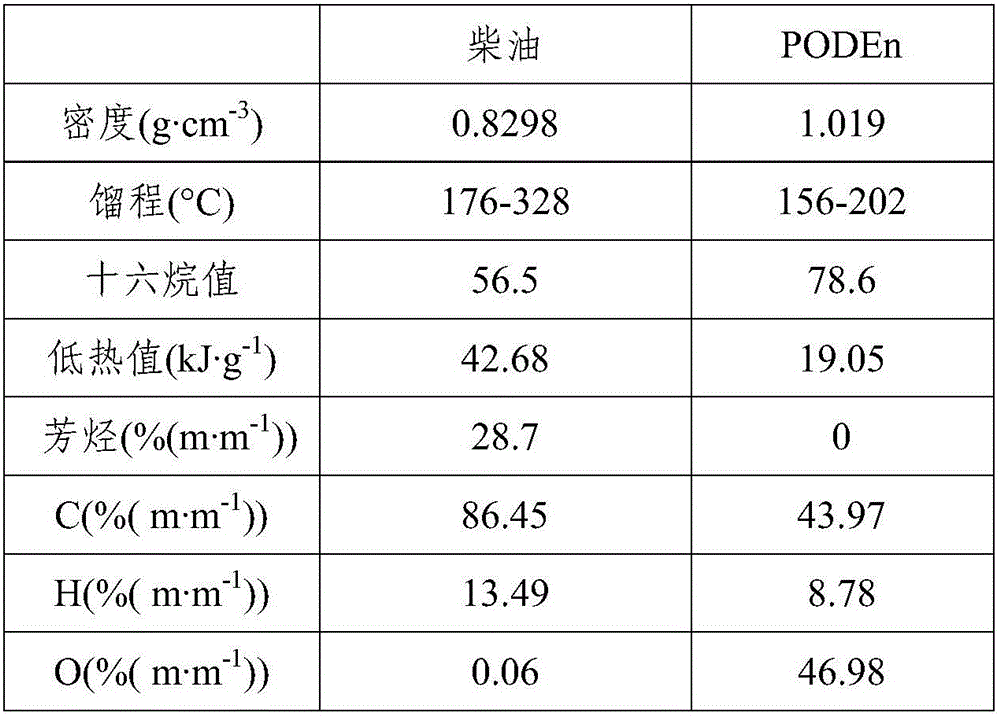

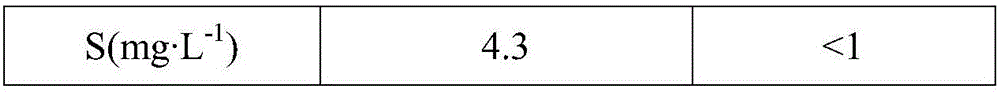

A technology of polyoxymethylene dimethyl ether and natural gas, which is applied in electrical control, combustion engine, fuel injection control, etc., can solve problems such as unreported natural gas technical solutions, and achieve the improvement of cetane number and oxygen content, Effect of lowering combustion temperature and reducing exhaust gas emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

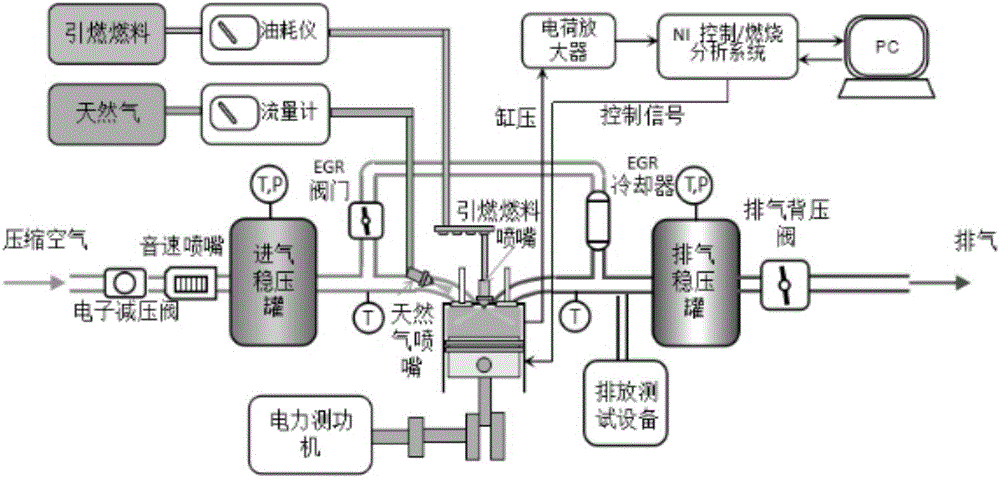

Method used

Image

Examples

Embodiment 1

[0027] The test adopts a single injection strategy, and the specific working conditions of the dual-fuel engine are shown in Table 3:

[0028] Table 3: Specific working conditions

[0029] parameter

value

Rotating speed

1000rpm

load

4bar IMEP

natural gas substitution rate

60%

EGR rate

0

1.2 bar

gas injection moment

350°CA BTDC

pilot fuel injection timing

25°CA BTDC

[0030] The test results obtained from the test are shown in Table 4:

[0031] Table 4: Test results of test example 1

[0032]

[0033]

[0034] After testing, after applying the combustion mode described in the present invention, under the same working conditions, compared with the traditional diesel combustion mode of igniting natural gas, CO, THC and NOx emissions are respectively reduced by 26.2%, 33.6% and 76.0%, Indicating a 7.2% increase in thermal efficiency.

Embodiment 2

[0036] The test adopts two injection strategies, and the specific working conditions of the dual-fuel engine are shown in Table 5:

[0037] Table 5: Specific working conditions

[0038] parameter

value

Rotating speed

1000rpm

load

12bar IMEP

natural gas substitution rate

80%

EGR rate

0

1.0 bar

gas injection moment

350°CA BTDC

pilot fuel first injection

10°CA BTDC

pilot fuel second injection

0°CA BTDC

[0039] The test results obtained from the test are shown in Table 6:

[0040] Table 6: Test results of test example 2

[0041]

[0042] After testing, after applying the combustion mode described in the present invention, under the same working conditions, compared with the traditional combustion mode of diesel igniting natural gas, CO, THC and emissions are respectively reduced by 40.7%, 21.3%, and NOx emissions are slightly reduced. increased, indicating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com