Method for Determination of Low Free Toluene Diisocyanate Content in Polyurethane Prepolymers

A technology of toluene diisocyanate and polyurethane prepolymer, which is applied in measurement devices, material separation, instruments, etc., can solve the problems of inaccurate low-concentration detection, low detection sensitivity, low resolution, etc., and can solve the problems of chromatographic peak tailing, High sensitivity and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Instrument

[0040] High performance liquid chromatography (waters company) including breeze 1525 pump, 2487 dual-wavelength ultraviolet detector, Nova-Pak SiO 2 Chromatographic column (3.9x150mm, id 604μm, waters company), the analysis software is empower;

[0041] (2) Reagents

[0042] The standard sample TDI was purchased from Bayer, Germany; the mobile phase 2,2,4-trimethylpentane and 1,4-dioxane were high-performance liquid chromatography grade reagents, purchased from Merck, Germany;

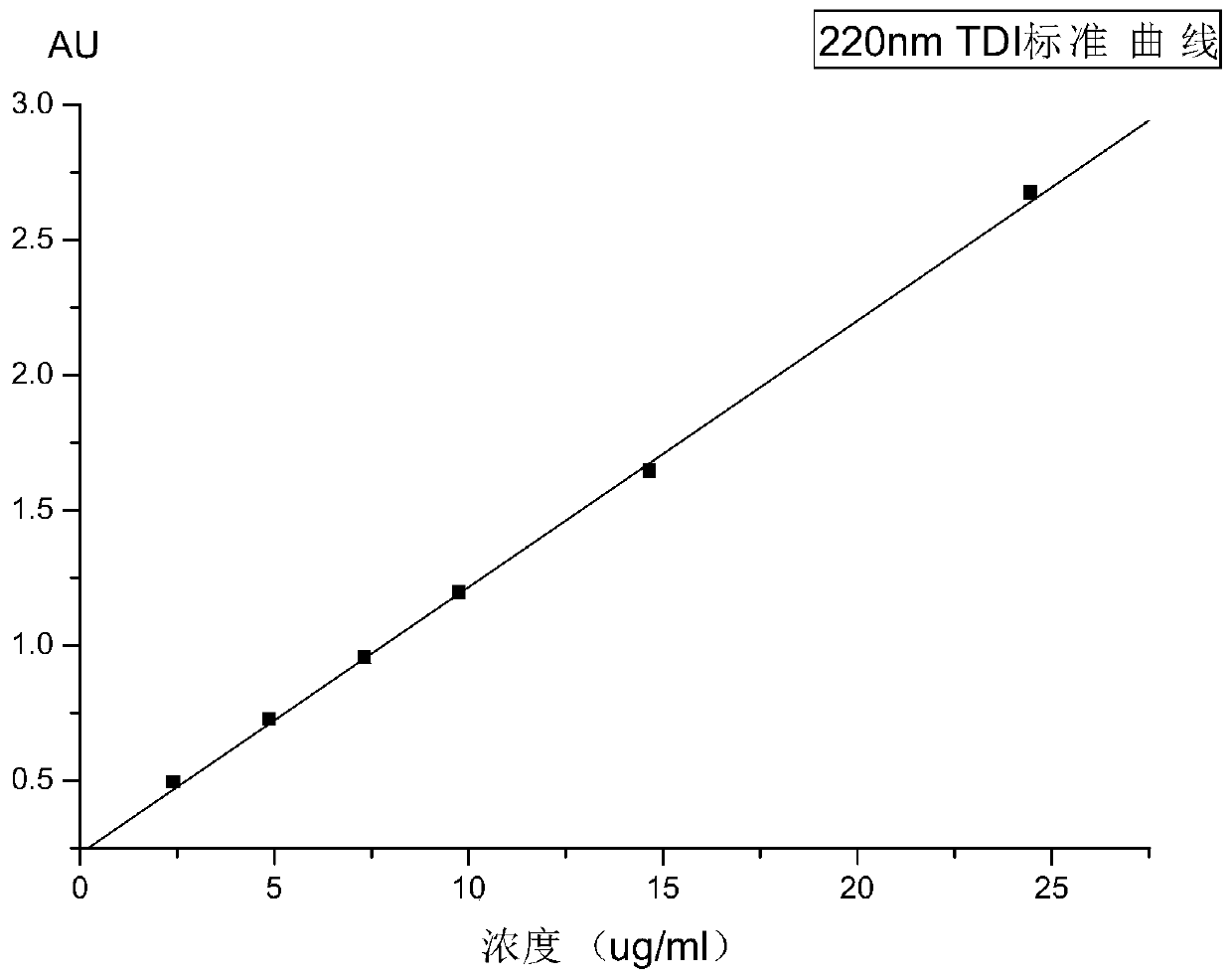

[0043] (3) Determination of standard curve

[0044] Accurately weigh 0.0980g of TDI standard reagent into a 100ml volumetric flask, add the initial mobile phase to dissolve, and configure it as a standard solution stock solution. Then take 0.5ml, 1ml, 1.5ml, 2ml, 3ml, 5ml of the above-mentioned stock solution and dissolve them into a 50ml volumetric flask with the initial mobile phase to configure the standard series, and take 10 μl of each standard series solution and use a ...

Embodiment 2

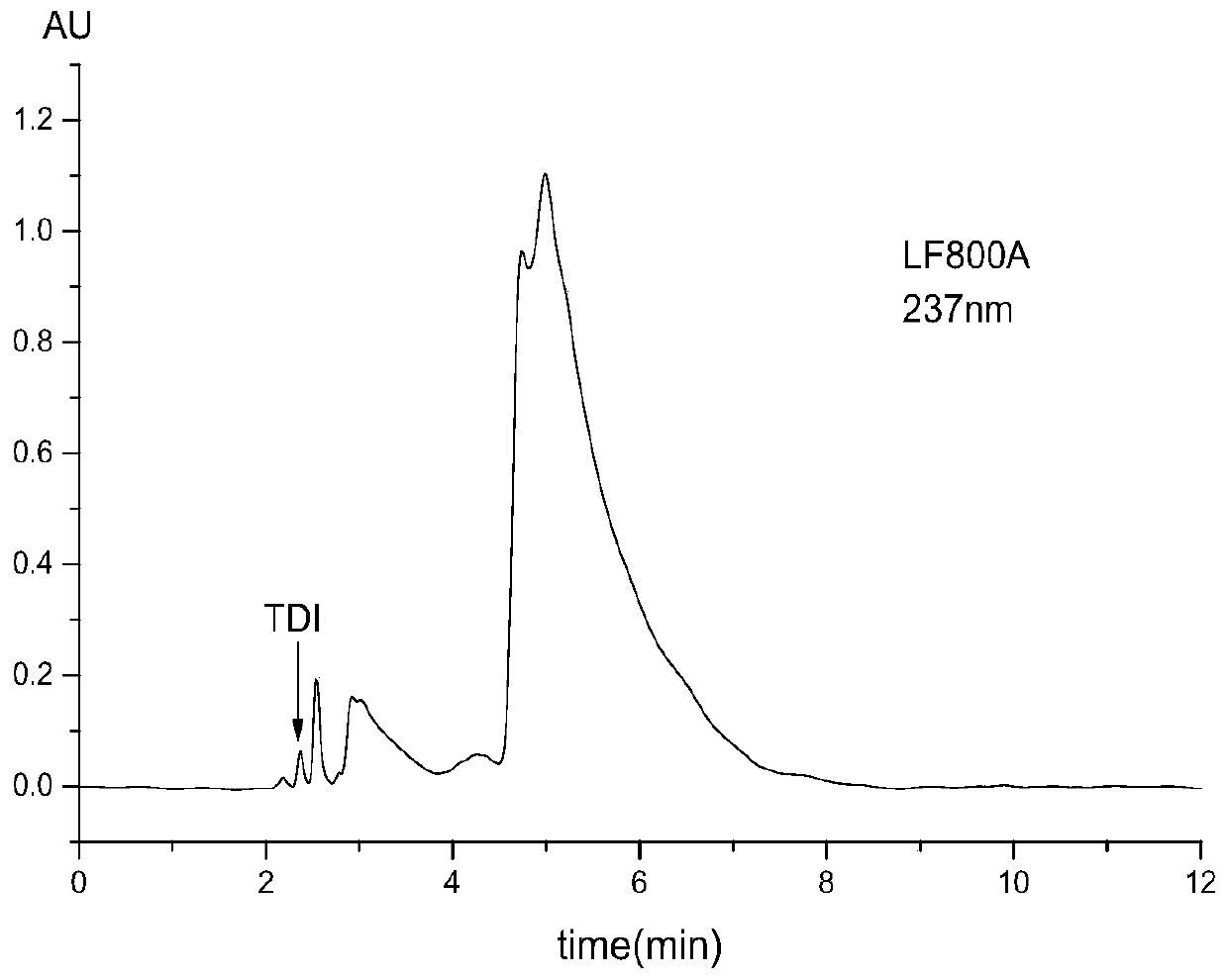

[0048] Accurately weigh 4.7148g sample LF800A (Chemtura, free TDI≤0.1wt%) and dissolve it in mobile phase to a 50ml volumetric flask to obtain the test solution. Adopt high performance liquid chromatograph gradient elution, ultraviolet detection wavelength 237nm, obtain chromatogram see image 3 , it can be seen that the peaks of the TDI components can achieve baseline separation, quantified by the peak area external standard method, and the concentrations measured twice in a row are 28.32ug / ml and 28.26ug / ml, and the free TDI monomer is calculated in the prepolymerization The content in the body is 0.030%. All the other are with embodiment 1.

Embodiment 3

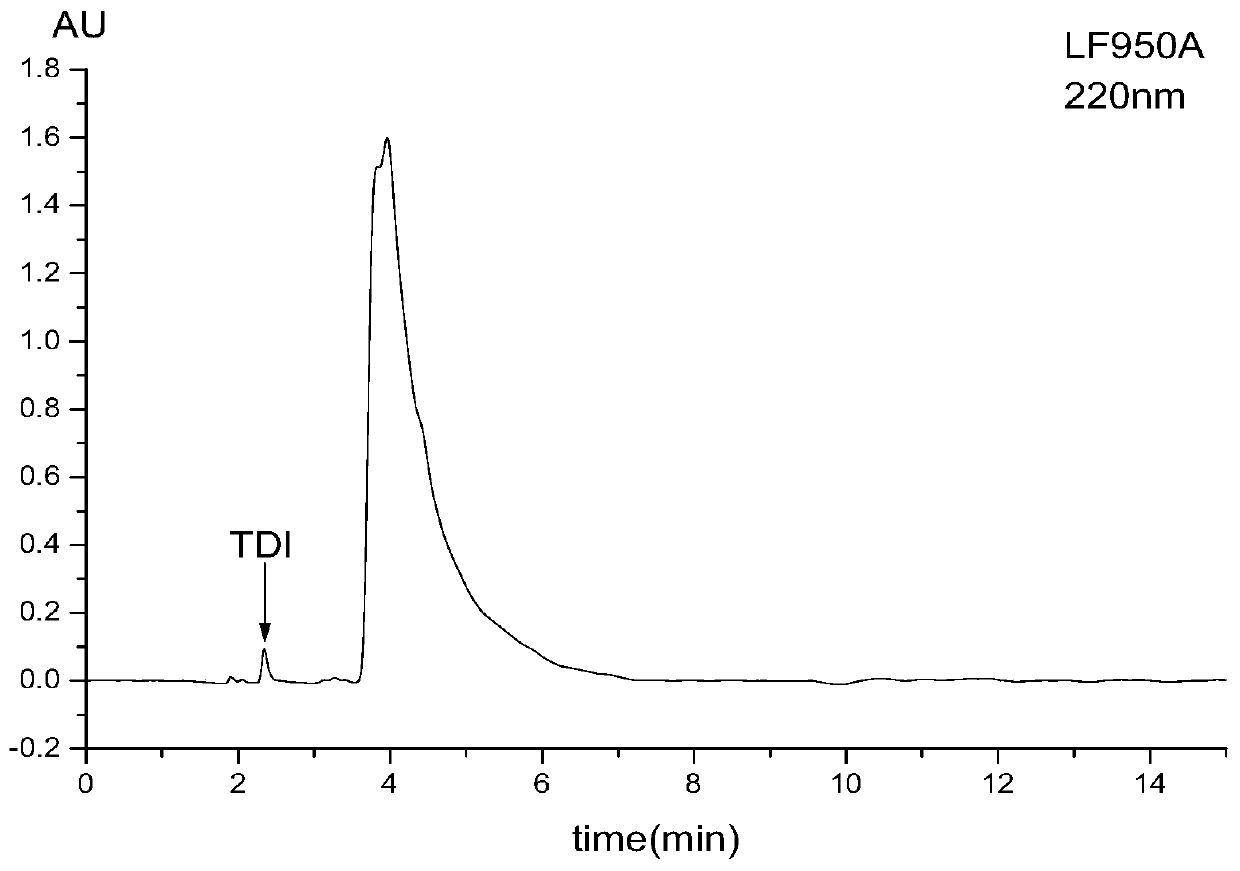

[0050] Accurately weigh 1.0215g sample LF950A (Chemtura, free TDI≤0.1wt%) and dissolve it in mobile phase to a 50ml volumetric flask to obtain the test solution. The liquid to be tested is injected into a liquid chromatograph for gradient elution, and the ultraviolet detection wavelength is 220nm. The peaks of the TDI components can be separated from the baseline, and quantified by the peak area external standard method, and the content of the free TDI monomer in the prepolymer is 0.043 %. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com