Random scattering medium based controllable sub-wavelength maskless photoetching system and method

A random scattering medium, maskless lithography technology, applied in the field of lithography, can solve the problems of limited application scope, cost increase, cost increase, etc., to achieve the effect of improving the field of view, reducing the cost of lithography, and improving time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

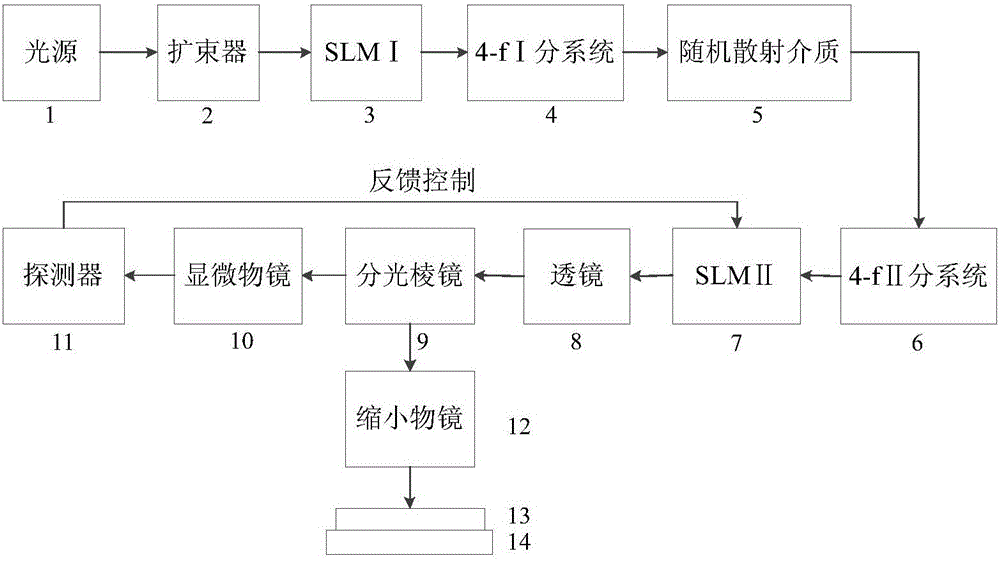

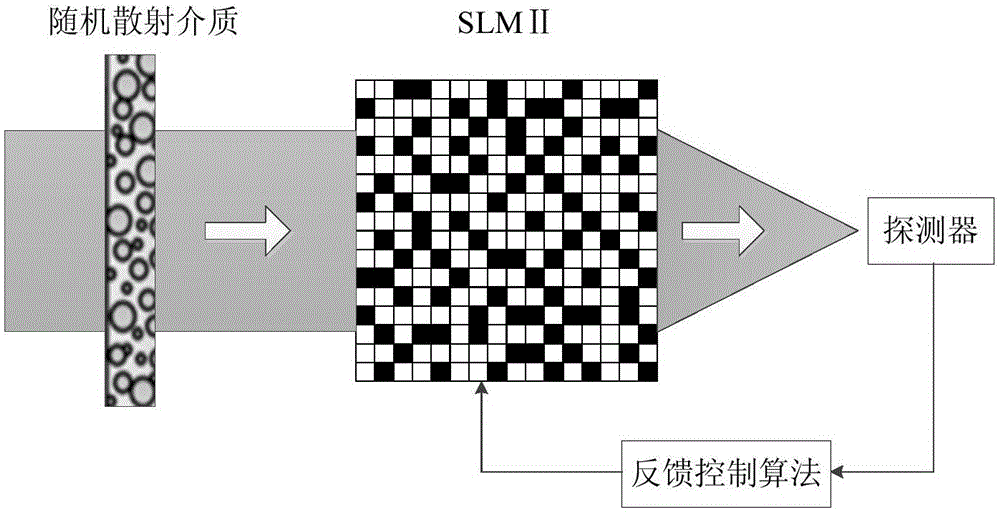

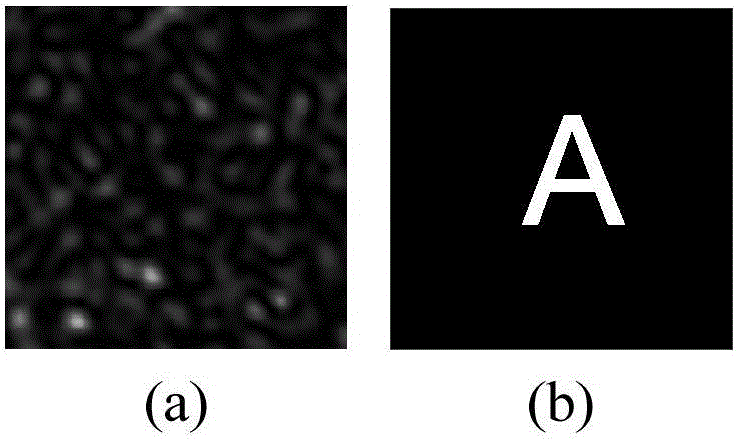

[0032] A controllable sub-wavelength maskless lithography system based on random scattering media. The light emitted by the light source 1 passes through the beam expander 2 and then irradiates on the spatial light modulator (SLM) Ⅰ3. The focused pattern is passed through the narrowing objective lens 12 The substrate 13 on the exposure table 14 is exposed to complete the photolithography exposure process, see figure 1 , the present invention adds a random scattering medium assembly and a feedback control subsystem between the reduction objective lens 12 and the spatial light modulator (SLM) I3; the random scattering medium assembly of the present invention is connected in series with 4-fI subsystems along the optical path direction 4. Random scattering medium 5, 4-fII subsystem 6; the feedback control subsystem of the present invention is connected in series after the 4-fII6 subsystem, and the feedback control subsystem is sequentially provided with a spatial light modulator (S...

Embodiment 2

[0035] The overall composition of the controllable sub-wavelength maskless lithography system based on random scattering medium is the same as that in Embodiment 1, and the 4-fI sub-system 4 of the present invention can use two lenses, wherein the front is a lens with a large focal length, and the rear is a system with a small focal length , can also be combined with a reduction objective lens and a lens, no matter which scheme can achieve beam reduction. 4-fII sub-system 6 can use two lenses, the front is a small focal length lens, and the back is a large focal length system, or a combination of a microscope objective lens and a lens can be used, no matter which scheme can achieve beam expansion. The focal lengths of all the lenses are selected according to the size of the two spatial light modulators and the required resolution.

Embodiment 3

[0037] The overall composition of the controllable sub-wavelength maskless lithography system based on random scattering medium is the same as that in Embodiment 1-2. The random scattering medium 5 either uses a strong scattering material or a high refractive index material whose surface is polished into a rough surface; according to this System imaging principle, the field of view of the entire lithography system is FOV≈λd / πL, and the axial variation range of the system is Δz FOV ≈2·FOV·d / D, the range in which the target changes axially, and changes within this range will not affect the subsequent imaging process. Where λ is the wavelength of the light source, d is the distance between the target and the random scattering medium, and L is the thickness of the random scattering medium, so a thin medium should be used. The random scattering medium used in this example is frosted glass (GROUND GLASS 100MM DIA TS, 62620EDMUND) with a particle size of 220. The present invention a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com