A high reliability power cable

A power cable, reliability technology, applied in the direction of power cables with shielding layer/conductive layer, insulated cables, cables, etc., can solve the problems of affecting processability, poor adhesion and self-adhesiveness, poor tear resistance, etc. , to achieve good tear strength, good processing performance, good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

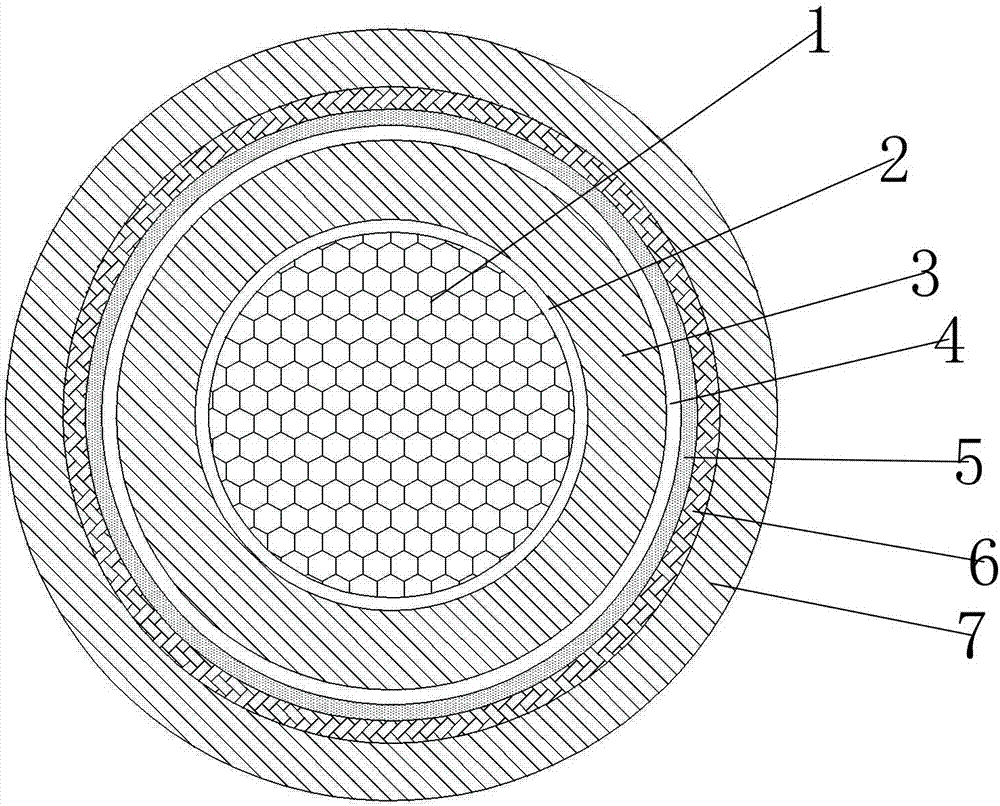

[0016] Embodiment 1: as figure 1 As shown, it includes multi-strand tinned annealed copper stranded conductor 1, Teflon tape wrapping layer 2 wrapped around multi-strand tinned annealed copper stranded conductor 1, and extruded Teflon tape wrapping layer 2 The outer rubber insulation layer 3, the aluminum-plastic composite tape shielding layer 4 wrapped around the rubber insulation layer 3, the 3M 8882 elastic insulating waterproof resin layer 5 outside the aluminum-plastic composite tape shielding layer 4, wrapped in 3M 8882 elastic insulation The PET braided mesh pipe refractory layer 6 outside the waterproof resin layer 5 is extruded and wrapped with a rubber outer sheath 7 outside the PET braided mesh pipe fireproof layer 6 .

[0017] The rubber material used for the rubber insulating layer and the rubber outer sheath of the high-reliability power cable is made through the following steps:

[0018] (1) 2.2 kg of nano-yttrium aluminate with an average particle size of 40nm...

Embodiment 2

[0022] Embodiment 2: The structure of a high-reliability power cable is the same as in Embodiment 1, except that the rubber material used for the rubber insulating layer and the rubber outer sheath is made through the following steps:

[0023] (1) 2 kg of nano-yttrium aluminate with an average particle size of 40 nm, 3 kg of nano-lanthanum trioxide with an average particle size of 50 nm, 5 kg of isopropanol, Nanjing Quanxi Chemical Co., Ltd. (QX-1613) hexadecyl trimethoxy 1.5 kg of silane and 4 kg of diethylene glycol monobutyl ether were mixed with a magnetic stirrer, stirred for 5 minutes, and then ultrasonically oscillated at 60-70°C for 150 minutes;

[0024] (2) Add 2 kg of secondary alcohol polyoxyethylene ether (S-50) to 50 times the weight of pure water and stir evenly, then add 8 kg of hydroxyapatite with an average particle size of 20um and silicon dioxide 28 with an average particle size of 2um 20 kg of dolomite powder with an average particle size of 5um and 8 kg of...

Embodiment 3

[0027] Embodiment 3: The structure of the high-reliability power cable is the same as that of Embodiment 1, except that the rubber material used for the rubber insulating layer and the rubber outer sheath is made by the following steps:

[0028] (1) 2.5 kg of nanometer yttrium aluminate with an average particle size of 40 nm, 3.5 kg of nanometer lanthanum trioxide with an average particle size of 50 nm, 6 kg of isopropanol, Nanjing Quanxi Chemical Co., Ltd. (QX-1613) hexadecyltrimethoxy Mix 2 kg of base silane and 5 kg of diethylene glycol monobutyl ether with a magnetic stirrer, stir for 5 minutes, and then ultrasonically vibrate for 150 minutes at 60-70 °C;

[0029] (2) Add 2.5 kg of secondary alcohol polyoxyethylene ether (S-50) to 50 times the weight of pure water, then add 10 kg of hydroxyapatite with an average particle size of 20 μm, 32 kg of silica with an average particle size of 2 μm, 22 kg of dolomite powder with an average particle size of 5um and 10 kg of magnesiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com