Composite feed for sheep

A sheep feed and mineral feed technology, which is applied in the field of compound sheep feed, can solve the problem that the growth needs of sheep cannot be fully met, and achieve the effects of improving feed conversion rate, rational formula and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

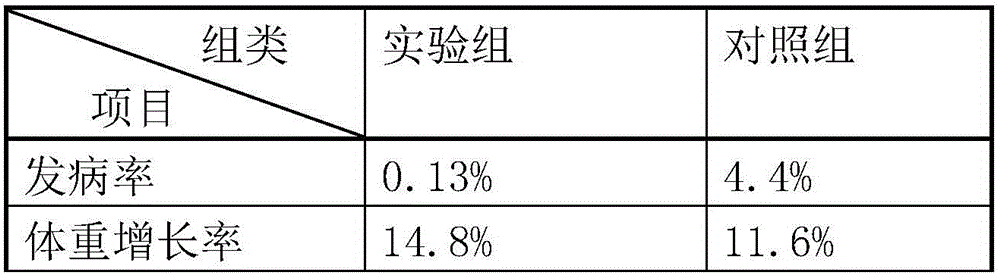

Image

Examples

Embodiment 1

[0019] A compound sheep feed, which is mainly made by pulverizing and mixing the following raw materials according to the proportion by weight:

[0020] Corn 60kg, soybean meal 20kg, peanut seedling 20kg, grape leaves 5kg, mulberry leaves 5kg, ryegrass 5kg, buckwheat 100kg, alfalfa 50kg, shell powder 3kg, salt 0.2kg, bone meal 10kg, probiotics 1kg, mineral feed 1kg, inorganic salt And vitamin additives 2.5kg.

[0021] The mineral feed consists of the following raw materials by weight: 40 kg of calcium carbonate and 40 kg of calcium bicarbonate.

[0022] The inorganic salt and vitamin additives are a mixture of copper sulfate, vitamin C and vitamin E in a mass ratio of 1:2:2.

[0023] The preparation method of described compound sheep feed, its preparation steps are as follows:

[0024] (1) Mix corn, soybean meal, peanut seedlings, grape leaves, mulberry leaves, ryegrass, buckwheat, and alfalfa according to the ratio and process them into powder;

[0025] (2) Pour all the re...

Embodiment 2

[0027] A compound sheep feed, which is mainly made by pulverizing and mixing the following raw materials according to the proportion by weight:

[0028] Corn 70kg, soybean meal 25kg, peanut seedling 25kg, grape leaves 8kg, mulberry leaves 8kg, ryegrass 8kg, buckwheat 150kg, alfalfa 65kg, shell meal 4kg, salt 0.3kg, bone meal 12kg, probiotics 2kg, mineral feed 2kg, inorganic salt And vitamin additive 3.5kg.

[0029] The mineral feed consists of the following raw materials by weight: calcium carbonate 45kg, calcium bicarbonate 50kg.

[0030] The inorganic salt and vitamin additives are a mixture of copper sulfate, vitamin C and vitamin E in a mass ratio of 1:2:2.

[0031] The preparation method of described compound sheep feed, its preparation steps are as follows:

[0032] (1) Mix corn, soybean meal, peanut seedlings, grape leaves, mulberry leaves, ryegrass, buckwheat, and alfalfa according to the ratio and process them into powder;

[0033] (2) Pour all the remaining raw ma...

Embodiment 3

[0035] A compound sheep feed, which is mainly made by pulverizing and mixing the following raw materials according to the proportion by weight:

[0036] Corn 80kg, soybean meal 30kg, peanut seedling 30kg, grape leaves 10kg, mulberry leaves 10kg, ryegrass 10kg, buckwheat 200kg, alfalfa 80kg, shell powder 5kg, salt 0.4kg, bone meal 15kg, probiotics 3kg, mineral feed 3kg, inorganic salt And vitamin additives 4.5kg.

[0037] The mineral feed consists of the following raw materials by weight: calcium carbonate 50kg, calcium bicarbonate 60kg.

[0038] The inorganic salt and vitamin additives are a mixture of copper sulfate, vitamin C and vitamin E in a mass ratio of 1:2:2.

[0039] The preparation method of described compound sheep feed, its preparation steps are as follows:

[0040] (1) Mix corn, soybean meal, peanut seedlings, grape leaves, mulberry leaves, ryegrass, buckwheat, and alfalfa according to the ratio and process them into powder;

[0041] (2) Pour all the remaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com