Vegetarian sausage and processing method thereof

A processing method and vegetarian technology, applied in the field of food processing, can solve the problems of poor taste and single nutrition, and achieve the effects of rich flavor, rich and comprehensive nutrition, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

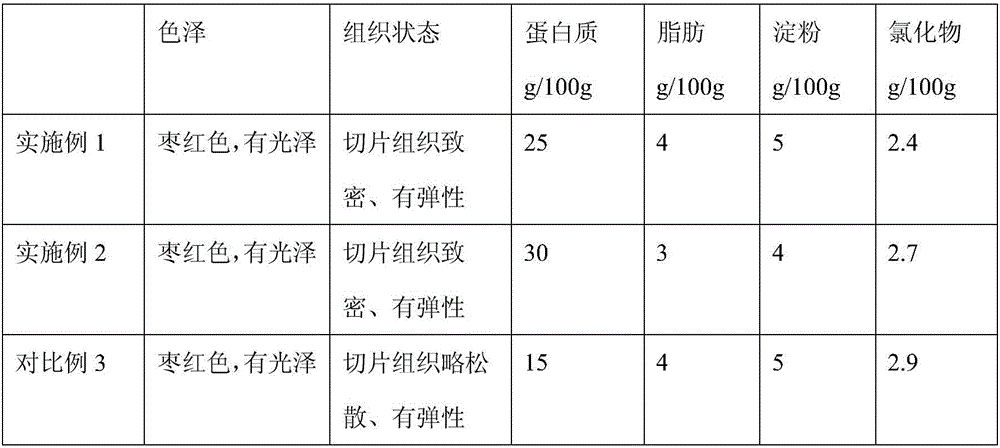

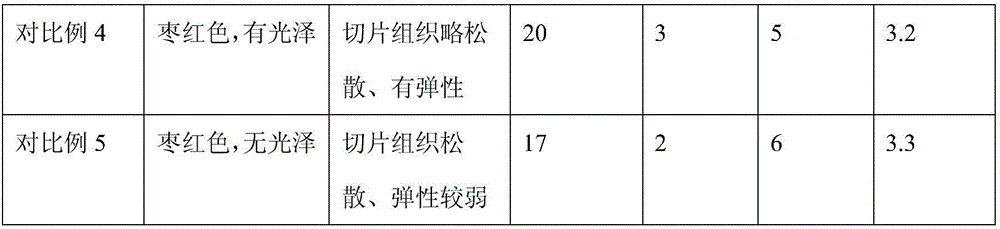

Examples

Embodiment 1

[0050] Embodiment 1 uses technical scheme of the present invention to process vegetarian sausage

[0051] A processing method of the above-mentioned vegetarian sausage, comprising the following steps:

[0052] a. Raw material handling

[0053] Process the soybean product into a powder of ≤5mm, stir the poultry egg liquid evenly, chop the celery and Coprinus comatus into 0.1-0.5cm fine powder; the soybean product is obtained by mixing soybeans:red beans:black beans=5:1:1 ;

[0054] b. Tumbling

[0055] Each raw material processed in step a is weighed according to the following parts by weight: 60 parts of soy products, 15 parts of poultry egg liquid, 20 parts of cornstarch, 5 parts of celery, 10 parts of Coprinus comatus, 5 parts of soybean oil, mix each raw material After mixing well, roll and knead for 10 minutes, and let stand for 15 minutes;

[0056] c. Mix and chop

[0057]Put the material obtained in step b into a chopping machine for high-speed chopping for 3 minute...

Embodiment 2

[0064] Embodiment 2 uses technical scheme of the present invention to process vegetarian sausage

[0065] A processing method of the above-mentioned vegetarian sausage, comprising the following steps:

[0066] a. Raw material handling

[0067] Process the soybean product into a powder of ≤5mm, stir the poultry egg liquid evenly, chop the celery and shiitake mushroom into 0.1-0.5cm fine powder; the soybean product is obtained by mixing soybean: red bean: black bean = 7:2:2;

[0068] b. Tumbling

[0069] Weigh the raw materials processed in step a according to the following parts by weight: 70 parts of soybean products, 20 parts of poultry egg liquid, 30 parts of cornstarch, 10 parts of celery, 20 parts of shiitake mushrooms, 10 parts of peanut oil, and mix the raw materials Finally, roll and knead for 20 minutes, and let stand for 30 minutes;

[0070] c. Mix and chop

[0071] Put the material obtained in step b into a chopping machine for high-speed chopping for 5 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com