A preparation method of graphene and octahedral ferrite composite magnetic nanomaterial

A technology of composite magnetic and nanomaterials, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., to achieve low pollution, good photocatalytic effect, and the effect of magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

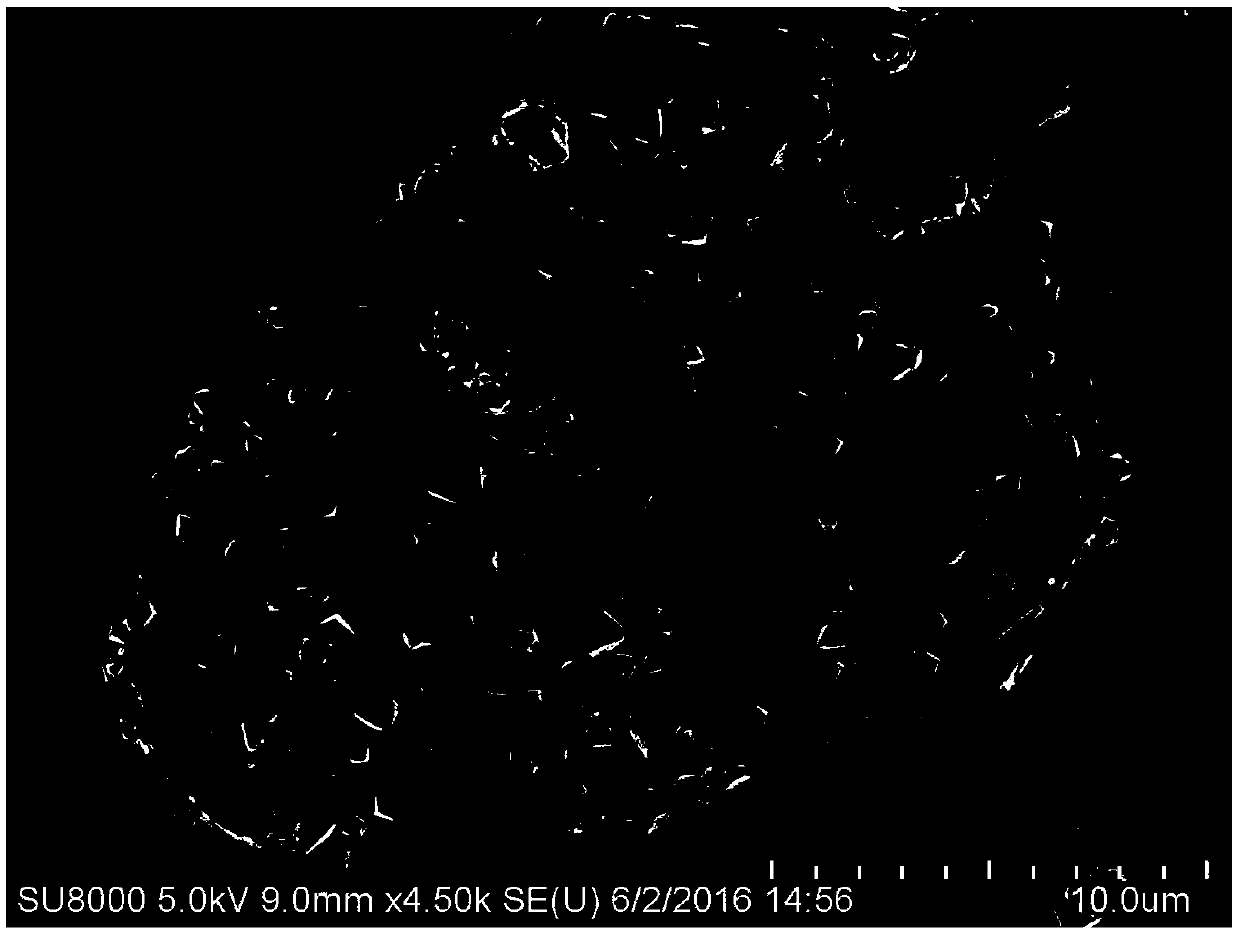

Image

Examples

Embodiment 1

[0023] A preparation method of graphene and octahedral ferrite composite magnetic nanomaterial

[0024] (1) Add 0.0456g GO to 4mL ethylene glycol, sonicate for 4h to form a black liquid;

[0025] (2) Put (0.728; 2mmol) Mg(NO 3 ) 2 ·6H 2 O and (1.612g; 4mmol) Fe(NO 3 ) 3 9H 2 O was dissolved in 20mL of ethylene glycol, and magnetically stirred at room temperature to form a transparent solution;

[0026] (3) While stirring, add (1.31g) NaAc and the black liquid obtained in the step (1) to the solution in step (2), and continue to stir for 60min;

[0027] (4) Add the reaction mixture of step (3) into a 50mL polytetrafluoroethylene stainless steel reactor, and react in an oven at 200°C for 12h;

[0028] (5) Then the reactor was cooled to room temperature, the black precipitate was collected, washed three times with absolute ethanol, and then dried at 60° C. for 6 h;

[0029] (6) Calcining the black powder obtained in step (5) at a heating rate of 2° C. / min at 650° C. for 2...

Embodiment 2

[0036] A preparation method of graphene and octahedral ferrite composite magnetic nanomaterial

[0037] (1) Add 0.0142g GO to 4mL ethylene glycol, and ultrasonicate to form a uniform black liquid;

[0038] (2) Put (0.728; 2mmol) Mg(NO 3 ) 2 ·6H 2 O and (1.612g; 4mmol) Fe(NO 3 ) 3 9H 2 Dissolve O in 40mL of ethylene glycol and stir magnetically at room temperature to form a transparent solution;

[0039] (3) While stirring, add (1.31g) NaAc and the black liquid obtained in the step (1) to the solution in step (2), and continue to stir for 60min;

[0040] (4) Add the reaction mixture of step (3) into a 50mL polytetrafluoroethylene stainless steel reactor, and react in an oven at 200°C for 12h;

[0041] (5) Then the reactor was cooled to room temperature, the black precipitate was collected, washed three times with absolute ethanol, and then dried at 60° C. for 6 h;

[0042] (6) Calcining the black powder obtained in step (5) at a heating rate of 2° C. / min at 650° C. for ...

Embodiment 3

[0044] A preparation method of graphene and octahedral ferrite composite magnetic nanomaterial

[0045] (1) Add 0.0142g GO to 4mL ethylene glycol, and ultrasonicate to form a uniform black liquid;

[0046] (2) Put (0.595; 2mmol) Zn(NO 3 ) 2 ·6H 2 O and (1.612g; 4mmol) Fe(NO 3 ) 3 9H 2 Dissolve O in 40mL of ethylene glycol and stir magnetically at room temperature to form a transparent solution;

[0047] (3) While stirring, add (1.31g) NaAc and the black liquid obtained in the step (1) to the solution in step (2), and continue to stir for 60min;

[0048] (4) Add the reaction mixture of step (3) into a 50mL polytetrafluoroethylene stainless steel reactor, and react in an oven at 200°C for 12h;

[0049] (5) Then the reactor was cooled to room temperature, the black precipitate was collected, washed three times with absolute ethanol, and then dried at 60° C. for 6 h;

[0050] (6) Calcining the black powder obtained in step (5) at a heating rate of 2° C. / min at 650° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com