High-efficiency and energy-saving thermal desorption treatment system for organic contaminated soil

An organic pollution, high-efficiency and energy-saving technology, applied in the field of soil remediation, can solve the problems of high processing cost, inability to accurately control system temperature, limited energy consumption, etc., achieve high concentration of organic pollutants, ensure soil remediation effect, and reduce waste gas treatment volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

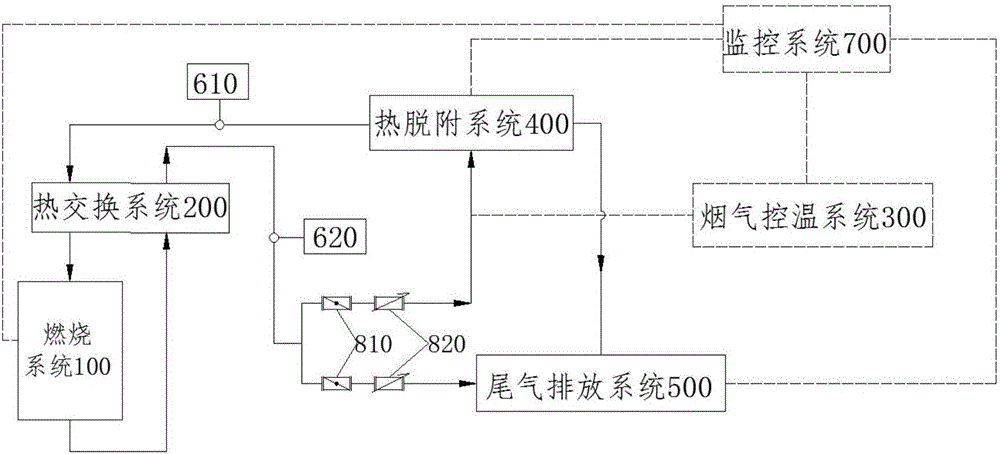

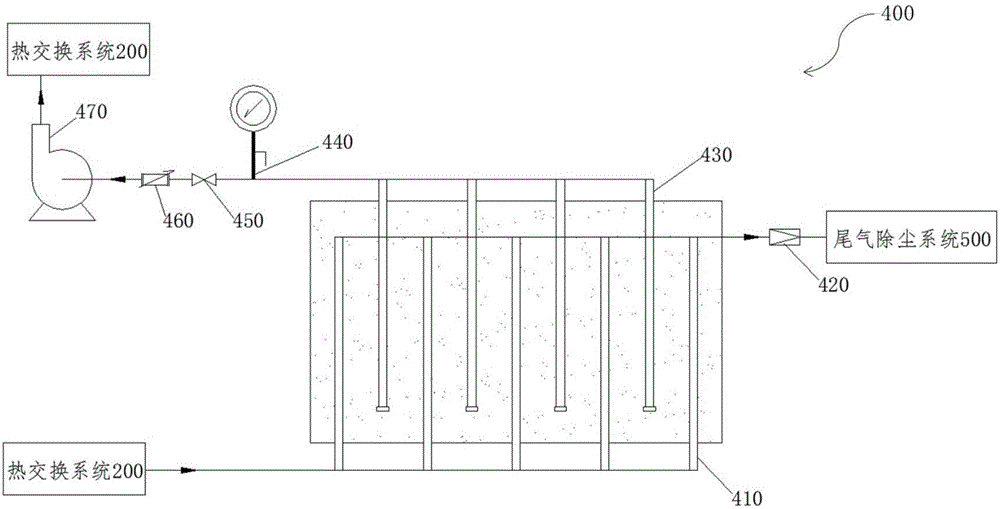

[0022] Such as figure 1 As shown, the present invention provides an efficient and energy-saving thermal desorption treatment system for organic polluted soil, including a combustion system 100, a heat exchange system 200, a flue gas temperature control system 300, a thermal desorption system 400, an exhaust gas discharge system 500, and a detection system and monitoring system 700 .

[0023] The combustion system 100 generates heat-carrying gas, which flows through the heat exchange system 200, and then is controlled by the regulating valve 810 and the flow meter 820, and part of it is passed into the thermal desorption system 400 to reach a preset temperature, heat the polluted soil, and generate Exhaust gas containing organic pollutants; the remaining part is passed into the tail gas discharge system 500 and discharged after dust remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com