Method for preparing hollow UO2 nanosphere through liquid crystal radiation

A nanosphere and hollow technology, which is applied in the field of preparation of uranium oxide nanomaterials, can solve the problems of difficulty in adjusting the cavity size, irregular shape of nanospheres, poor rigidity of bubble templates, etc., and achieves the effect of regular shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

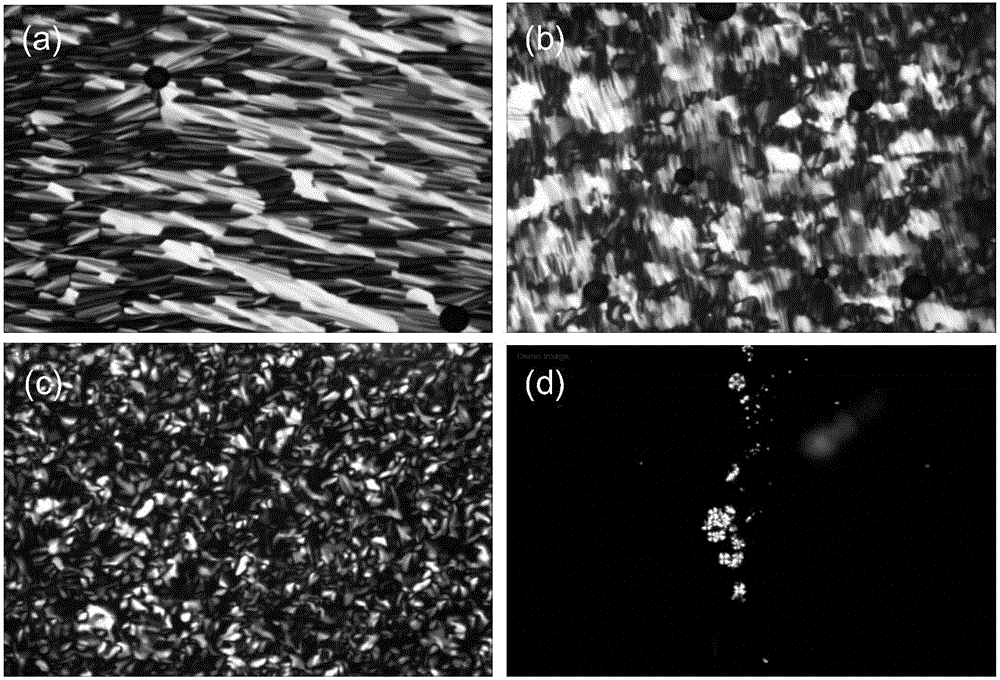

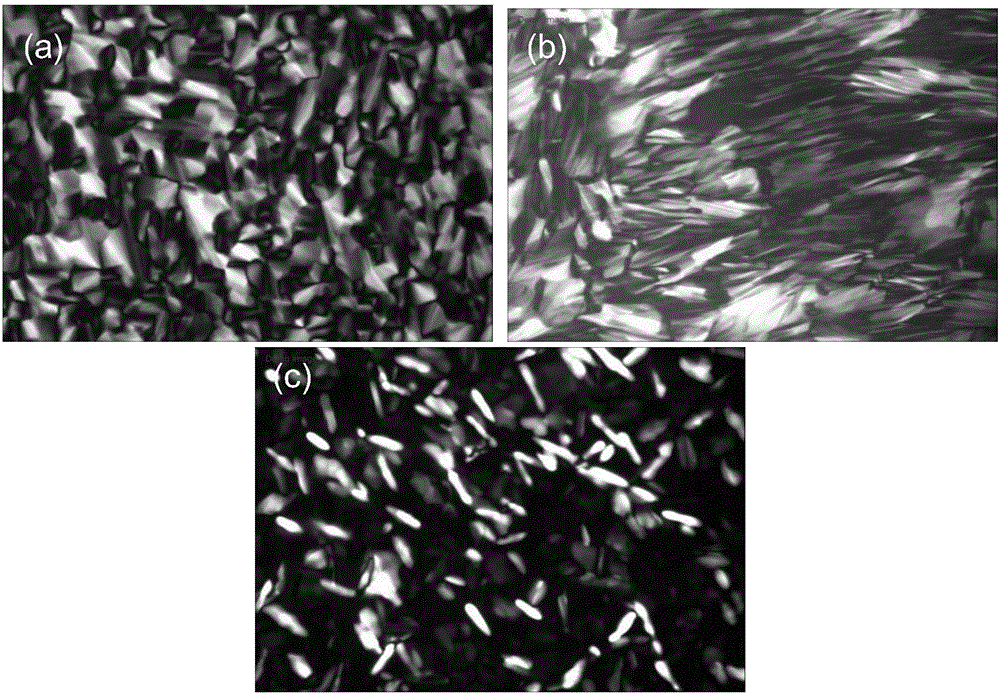

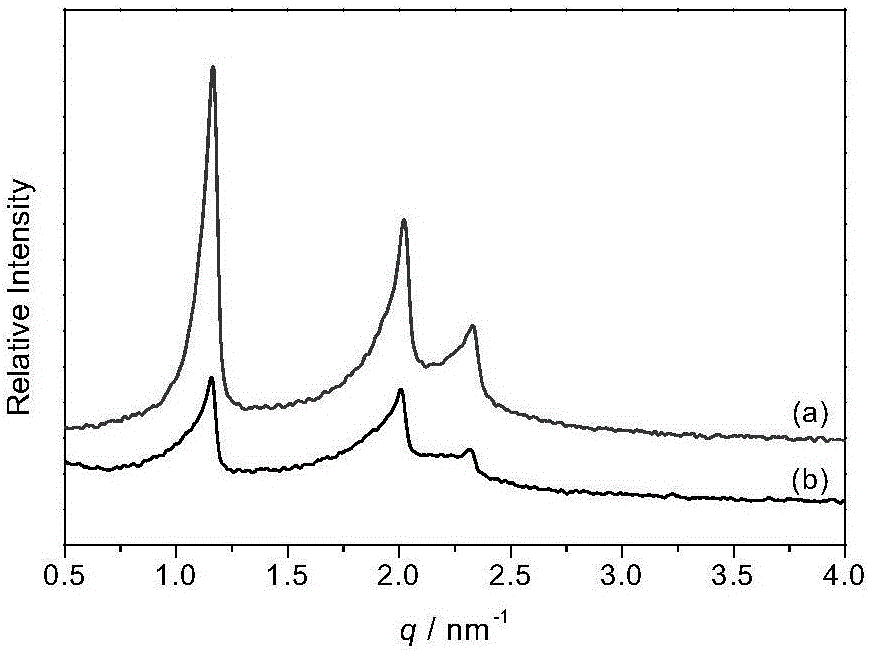

Image

Examples

Embodiment Construction

[0032] 1. Experimental method

[0033] 1. Experimental reagents

[0034] UO 2 (NO 3 ) 2 ·6H 2 O, GR, Chemapol, Prague Czechoslovakia. NH 4 HCO 3 、Na 2 CO 3 , ammonium formate (HCOONH 4 ) were analytically pure and used directly. The experimental water was ultrapure water.

[0035] 2. Synthesis of Ammonium Uranyl Tricarbonate

[0036] According to the reference [31] , the UO 2 (NO 3 ) 2 ·6H 2 O was heat-treated in a muffle furnace at 350 °C for 3 hours to obtain yellow uranium trioxide powder. In a water bath at 60°C, a certain amount of saturated NH 4 HCO 3 The solution was slowly added dropwise to the 3 In a round-bottomed flask, stir until the yellow solid is completely dissolved, filter while hot, and transfer the filtrate into a beaker to cool and stand for crystallization. The crystals were collected by suction filtration and washed with 3wt% NH 4 HCO 3 Washed and dried in vacuo to obtain uranyl carbonate amide (AUC). The elemental analysis results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com