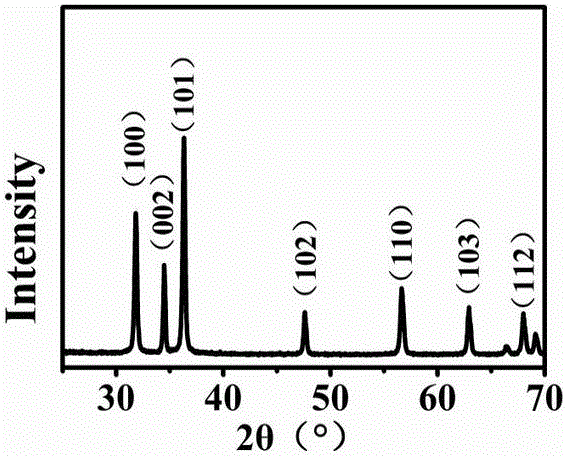

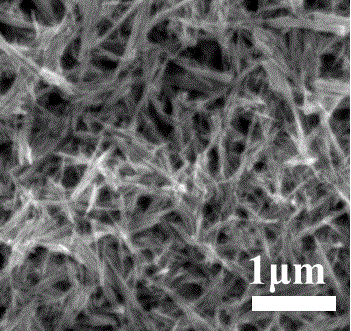

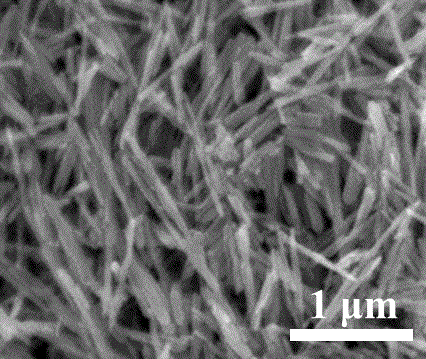

Preparation method of size-controllable mono-crystalline zinc oxide nano-rods

A zinc oxide nanorod, single crystal technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, single crystal growth, etc., can solve the problem of poor size controllability of zinc oxide nanorods, easy aggregation, and operation. The process is cumbersome and other problems, to achieve the effect of easy size, good repeatability, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dissolve 0.6g of zinc acetate dihydrate in a mixed solution of 3mL of acetic acid and 37mL of diethylene glycol, stir at room temperature until the particles are completely dissolved to obtain a clear solution, transfer the clear solution to a 50mL polytetrafluoroethylene liner, and seal it in The reaction was heated at 150° C. for 6 h in a constant temperature drying oven, and the white precipitate formed by the reaction was washed twice with deionized water and ethanol in turn, and then vacuum-dried at 60° C. to obtain single crystal zinc oxide nanorods ZnO-NR1.

Embodiment 2

[0019] Dissolve 0.8g of zinc acetate dihydrate in a mixed solution of 3mL of acetic acid and 37mL of diethylene glycol, stir at room temperature until the particles are completely dissolved to obtain a clear solution, transfer the clear solution to a 50mL polytetrafluoroethylene liner, seal it in The reaction was heated at 150° C. for 6 hours in a constant temperature drying oven, and the white precipitate formed by the reaction was washed twice with deionized water and ethanol in turn, and then vacuum-dried at 60° C. to obtain single crystal zinc oxide nanorods ZnO-NR2.

Embodiment 3

[0021] Dissolve 1g of zinc acetate dihydrate in a mixed solution of 3mL of acetic acid and 37mL of diethylene glycol, stir at room temperature until the particles are completely dissolved to obtain a clear solution, transfer the clear solution to a 50mL polytetrafluoroethylene liner, seal it and place it at a constant temperature The reaction was heated at 150°C in a drying oven for 6h, and the white precipitate formed by the reaction was washed twice with deionized water and ethanol in turn, and then dried in vacuum at 60°C to obtain single crystal zinc oxide nanorods ZnO-NR3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com