Preparation method of PDMS in-situ wrinkled antireflection film and monochromatic light organic light emitting diode

A technology of light-emitting diodes and anti-reflection coatings, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices. Light extraction efficiency and final external quantum efficiency, the effects of a wide range of options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In this example,

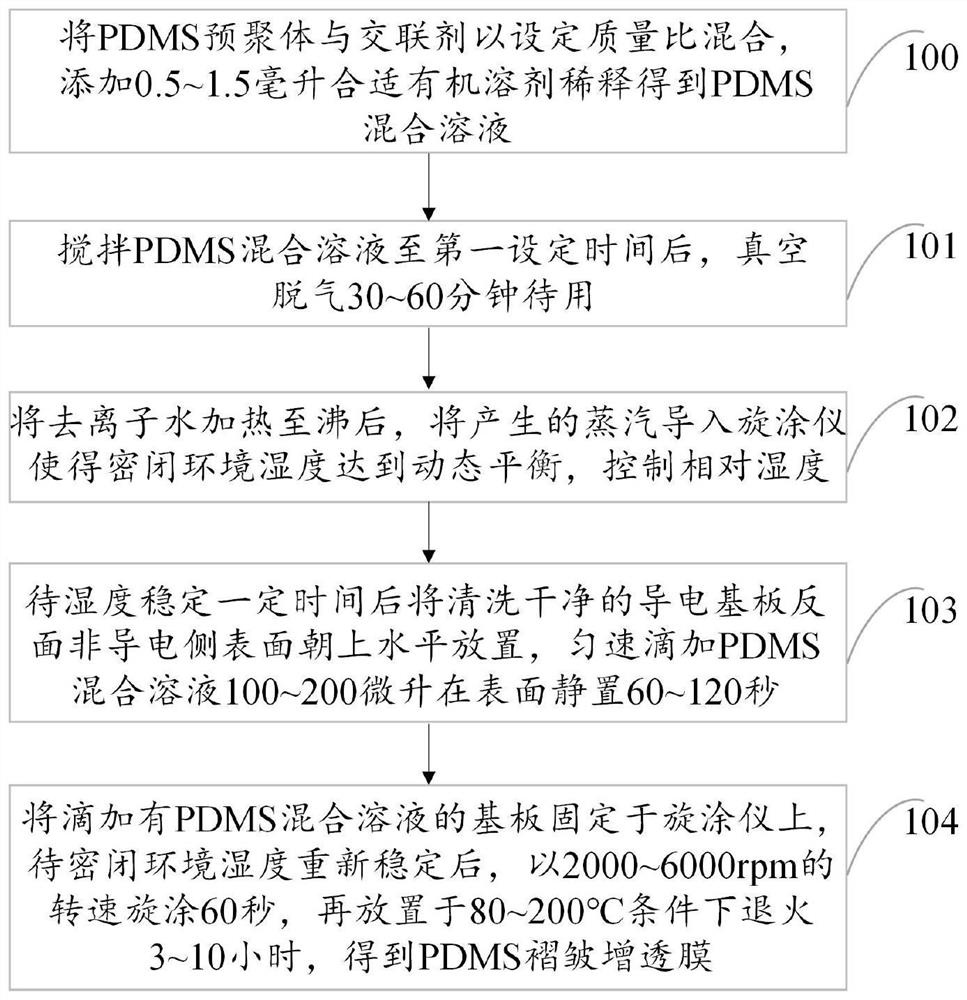

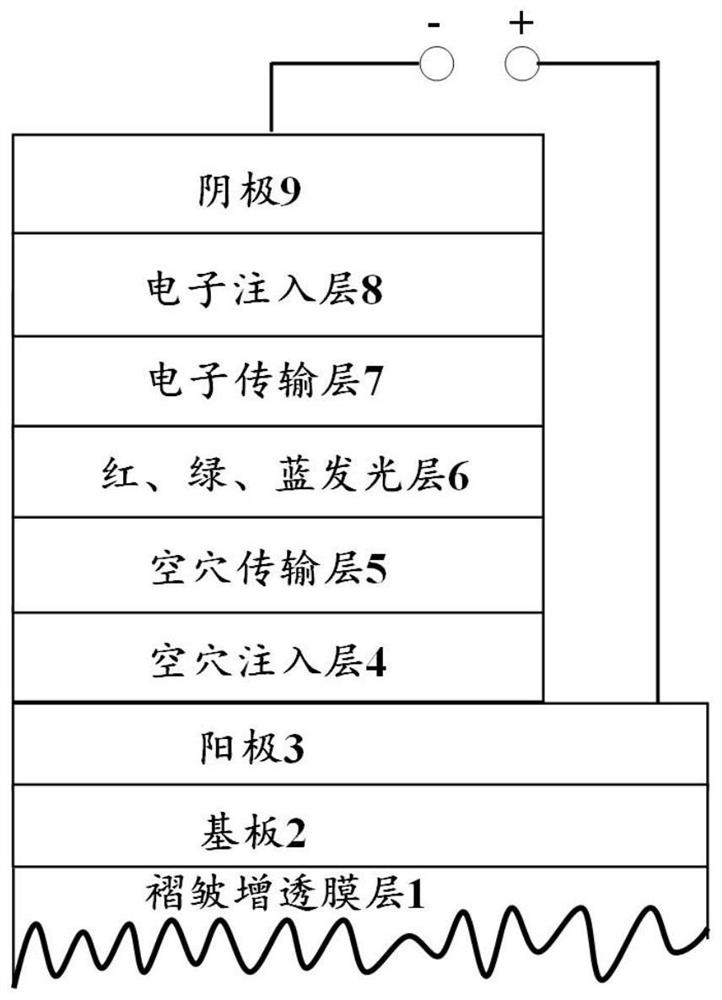

[0056] see figure 1 and figure 2 , a method for preparing a PDMS in-situ wrinkled anti-reflection film and a monochromatic organic light-emitting diode, comprising the steps of:

[0057] Step 100: According to the ratio of the mass ratio of PDMS prepolymer and PDMS crosslinking agent to 10:1, weigh 3.3 g of PDMS prepolymer and PDMS crosslinking agent, add them into clean transparent reagent bottles, and take 0.5 g respectively mL, 1.0mL and 1.5mL of chloroform were mixed with PDMS solution;

[0058] Step 101: Stir evenly, seal, and place the mixed solution in a moderate vacuum environment for degassing for 1 hour;

[0059] Step 102: After heating the deionized water to boiling, the generated steam is introduced into the spin coater so that the humidity in the airtight environment reaches a dynamic balance, and the relative humidity is controlled to be 75%;

[0060] Step 103: After ultrasonically cleaning the ITO glass substrate with detergent, ac...

Embodiment 2

[0069] This embodiment is basically the same as Embodiment 1, especially in that:

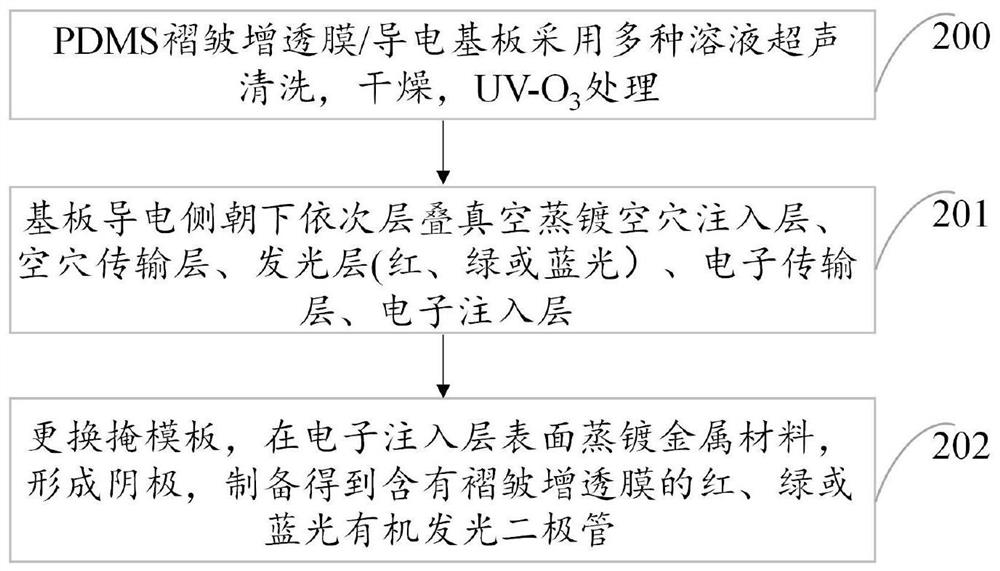

[0070] In this embodiment, a method for preparing a PDMS in-situ wrinkled anti-reflection film and a monochromatic organic light-emitting diode includes the following steps:

[0071] Step 100: According to the ratio of the mass ratio of PDMS prepolymer and PDMS crosslinking agent to 10:1, weigh 3.3g of PDMS prepolymer and PDMS crosslinking agent, add it to a clean transparent reagent bottle, and take 1.0mL Chloroform is mixed with PDMS solution;

[0072] Step 101~step 200: this step is the same as that of Embodiment 1;

[0073] Step 201: Place the conductive side of the substrate in step 200 down in a vacuum evaporation chamber to sequentially evaporate various functional layers, including MoO 3 (5nm) / NPB(35nm) / mCP(5nm) / DMAC-DPS:DPEPO(10wt%, 20nm) / DPEPO(10nm) / Bphen(40nm) / LiF(0.8nm);

[0074] Step 202: Finally, replace the mask to vapor-deposit cathode metal Al to prepare an electrode cathode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com