Ultrasonic auxiliary acid extracting method for optimizing collagen through response surface method

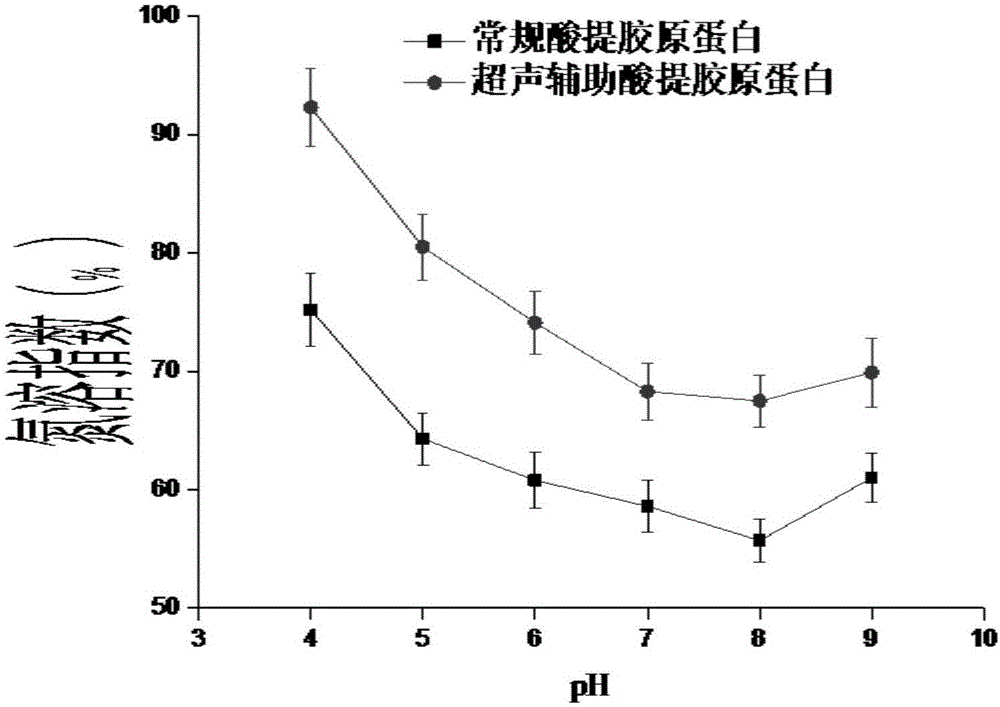

A collagen, ultrasound-assisted technology, applied in the preparation methods of peptides, chemical instruments and methods, animal/human proteins, etc., can solve the problems of a large amount of hazardous waste, large amount of reagents, long extraction time, etc., and achieve short processing time. , Solubility improvement, the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An ultrasonic-assisted acid extraction method utilizing response surface methodology to optimize collagen, comprising the following steps:

[0038] Step 1: Take fresh or frozen soft-shelled soft-shelled turtle skirt and chop it, then add NaCl solution with a mass fraction of 2.0% at a material-to-liquid ratio of 1:20, and stir at 20°C for 9 hours. After homogenizing at 8000rpm at high speed for 2min, the precipitate was collected once, and 0.5mol / L of Na was added with a solid-liquid ratio of 1:20 2 CO 3 The solution was stirred at 20°C for 9h. Then, after high-speed homogenization at 8000 rpm for 2 minutes, the secondary precipitate was collected, and 0.3 mol / L EDTA aqueous solution was added to soak and remove impurities at a solid-liquid ratio of 1:25. Stir at 20°C for 10 h, then homogenize at 8000 rpm for 2 min at high speed, collect three precipitates, wash repeatedly with distilled water, drain fully and set aside. Then add isopropanol solution with a mass frac...

Embodiment 2

[0051] An ultrasonic-assisted acid extraction method utilizing response surface methodology to optimize collagen, comprising the following steps:

[0052] Step 1: Take fresh or frozen soft-shelled soft-shelled turtle skirt and chop it, then add NaCl solution with a mass fraction of 1.0% at a material-liquid ratio of 1:10, and stir at 20°C for 6 hours. Then, after high-speed homogenization at 5000rpm for 1min, the precipitate was collected once, and 0.3mol / L Na was added with a solid-liquid ratio of 1:10. 2 CO 3 The solution was stirred at 20°C for 6h. Then, after high-speed homogenization at 5000 rpm for 1 min, the secondary precipitate was collected, and 0.2 mol / L EDTA aqueous solution was added to soak and remove impurities at a solid-liquid ratio of 1:20. Stir at 20°C for 6 hours, then homogenize at 5,000 rpm for 1 minute at high speed, collect three precipitates, wash repeatedly with distilled water, drain well and set aside. Then add isopropanol solution with a mass fr...

Embodiment 3

[0055] An ultrasonic-assisted acid extraction method utilizing response surface methodology to optimize collagen, comprising the following steps:

[0056] Step 1: Take fresh or frozen soft-shelled soft-shelled turtle skirt and chop it, then add NaCl solution with a mass fraction of 3.0% at a material-to-liquid ratio of 1:30, and stir at 20°C for 2 hours. Then, after high-speed homogenization at 10000rpm for 3min, the precipitate was collected once, and 0.6mol / L Na was added with a solid-liquid ratio of 1:30. 2 CO 3 The solution was stirred at 20°C for 12h. Then, after high-speed homogenization at 10,000 rpm for 3 minutes, the secondary precipitate was collected, and 0.4 mol / L EDTA aqueous solution was added to soak and remove impurities at a solid-liquid ratio of 1:30. Stir at 20°C for 12 hours, then homogenize at 10,000 rpm for 3 minutes at high speed, collect three precipitates, wash repeatedly with distilled water, drain fully and set aside. Then add isopropanol solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com