Preparation technology for extracting dendrobium officinale polysaccharide and polysaccharide instant powder with ultrasonic assisted negative pressure cavitation method

A technology of Dendrobium officinale polysaccharide and negative pressure cavitation is applied in the field of extraction and purification of Dendrobium officinale polysaccharide to achieve the effects of maintaining integrity, good dispersibility and fluidity, and reducing spray temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

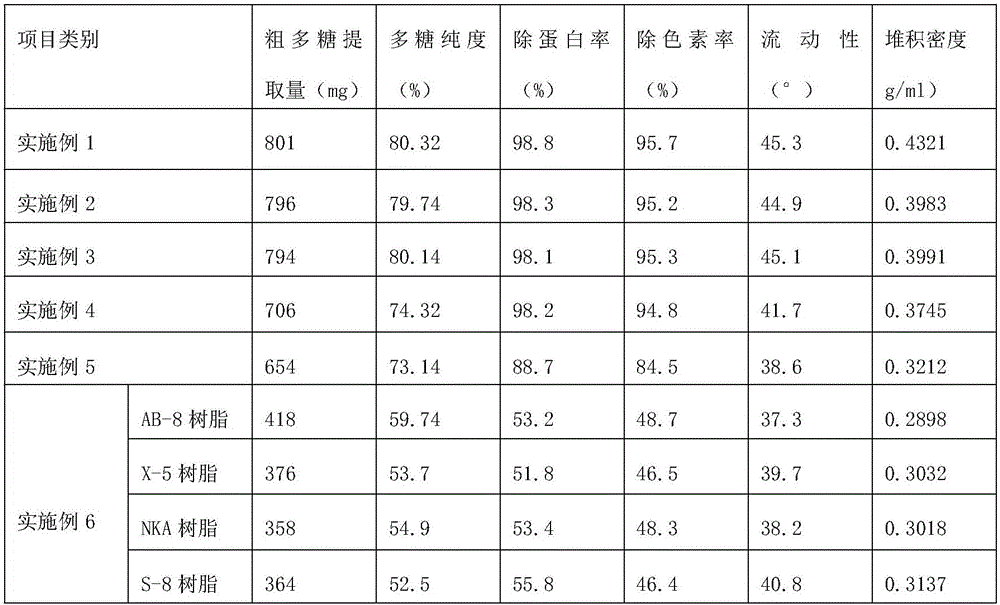

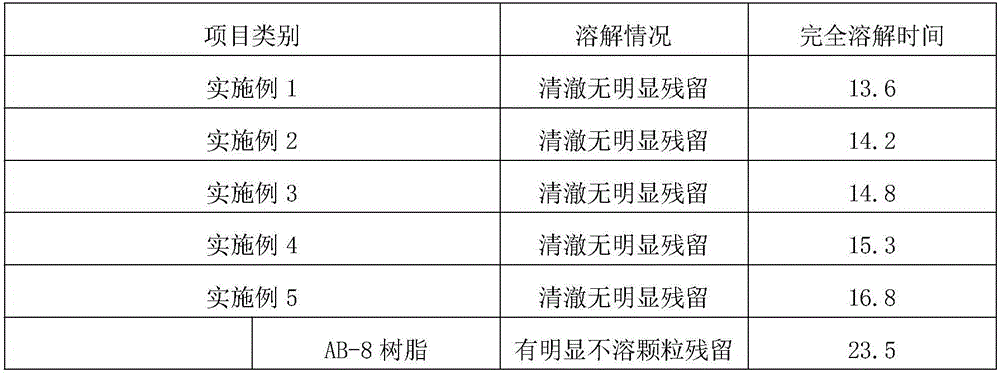

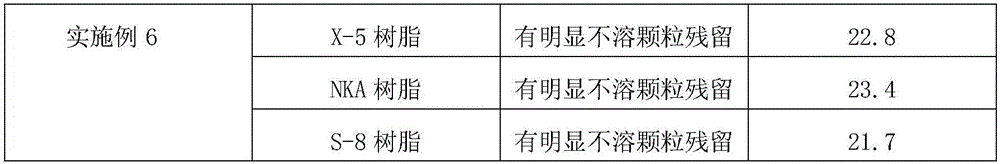

Examples

Embodiment 1

[0021] Ultrasonic-assisted negative pressure cavitation method to extract polysaccharides from Dendrobium officinale and the preparation technology of its instant powder are as follows:

[0022] (1) Dendrobium officinale polysaccharide ultrasonic-assisted negative pressure cavitation extraction process: take 100 g of dried stems of Dendrobium officinale, pulverize through a 60-mesh sieve, and use petroleum ether to reflux extract it for 3 hours according to the liquid-solid mass-volume ratio of 10ml:1g. The degreased medicinal material is obtained, and the obtained degreased medicinal material is extracted with distilled water according to the liquid-solid mass volume ratio of 10ml:1g negative pressure ultrasonic extraction, the extraction temperature is 70°C, the ultrasonic extraction time is 1h, the ultrasonic frequency is 50kHz, and the negative pressure strength is -0.05Mpa , extract twice, collect the water extract, and concentrate the water extract to one-tenth of the ext...

Embodiment 2

[0026] Ultrasonic-assisted negative pressure cavitation method to extract polysaccharides from Dendrobium officinale and the preparation technology of its instant powder are as follows:

[0027] (1) Ultrasonic-assisted negative pressure cavitation extraction process of Dendrobium officinale polysaccharides: take 100 g of dried stems of Dendrobium officinale, crush them through a 60-mesh sieve, and use cyclohexane to reflux extract them for 2 hours according to the liquid-solid mass volume ratio of 8ml:1g , to obtain the degreased medicinal material, the obtained degreased medicinal material is extracted with distilled water according to the liquid-solid mass volume ratio of 8ml:1g negative pressure ultrasonic extraction, the extraction temperature is 68°C, the ultrasonic extraction time is 0.8h, the ultrasonic frequency is 45kHz, and the negative pressure intensity is - 0.03Mpa, extract twice, collect the water extract, and concentrate the water extract to one-tenth of the extr...

Embodiment 3

[0031] Ultrasonic-assisted negative pressure cavitation method to extract polysaccharides from Dendrobium officinale and the preparation technology of its instant powder are as follows:

[0032] (1) Dendrobium officinale polysaccharide ultrasonic-assisted negative pressure cavitation extraction process: get the dried stem of Dendrobium officinale 100g, pulverize through a 60-mesh sieve, and use ether to carry out reflux extraction to it for 4 hours according to the liquid-solid mass volume ratio of 12ml:1g, to obtain After degreasing the medicinal materials, the obtained degreasing medicinal materials are extracted with distilled water according to the liquid-solid mass volume ratio of 12ml:1g negative pressure ultrasonic extraction, the extraction temperature is 72°C, the ultrasonic extraction time is 1.2h, the ultrasonic frequency is 55kHz, and the negative pressure strength is -0.07Mpa , extract twice, collect the water extract, and concentrate the water extract to one-tenth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com