Interior wall mildew-proof coating and preparation method thereof

A mildew-proof and coating technology, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of long-term effect, poor heat resistance and safety, low sterilization efficiency, etc., and achieve excellent water resistance Alkali resistance, low manufacturing cost, and strong brush resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

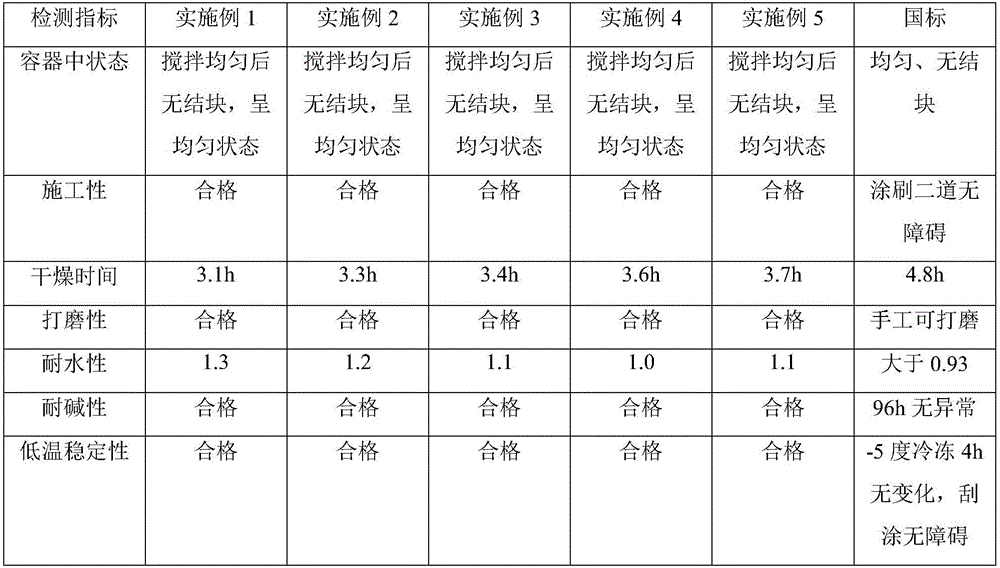

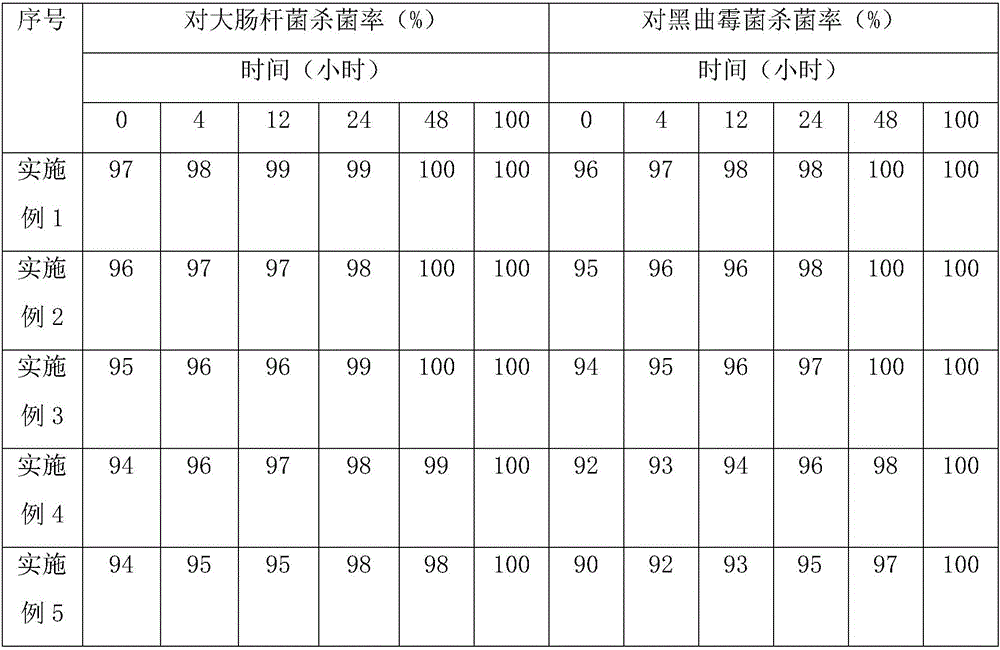

Examples

Embodiment 1

[0016] An anti-mildew coating for interior walls, made of the following raw materials in parts by weight: 26 parts of butyl acrylate, 20 parts of dibutyl phthalate, 24 parts of elastic emulsion, 17 parts of nonylphenol polyoxyethylene ether, titanium 23 parts of white powder, 14 parts of guar gum, 26 parts of azodicarbonamide, 22 parts of 1,2-benzisothiazolin-3-one, 14 parts of water-soluble silicone oil, and 24 parts of deionized water.

[0017] The preparation method of the anti-mildew coating for interior walls is characterized in that it comprises the following steps:

[0018] (1) In the dispersion kettle, add butyl acrylate, dibutyl phthalate, elastic emulsion and nonylphenol polyoxyethylene ether, stir at 1800r / min for 8min to obtain mixture A;

[0019] (2) In the dispersion kettle, add titanium dioxide, guar gum, azodicarbonamide, 1,2-benzisothiazolin-3-one, water-soluble silicone oil and deionized water, at a speed of 3500r / min Stir for 15min to obtain mixture B;

[...

Embodiment 2

[0022] An anti-mildew coating for interior walls, made of the following raw materials in parts by weight: 20 parts of butyl acrylate, 15 parts of dibutyl phthalate, 20 parts of elastic emulsion, 10 parts of nonylphenol polyoxyethylene ether, titanium 20 parts white powder, 10 parts guar gum, 10 parts azodicarbonamide, 20 parts 1,2-benzisothiazolin-3-one, 10 parts water-soluble silicone oil, 20 parts deionized water.

[0023] The preparation method of the anti-mildew coating for interior walls is characterized in that it comprises the following steps:

[0024] (1) In the dispersion kettle, add butyl acrylate, dibutyl phthalate, elastic emulsion and nonylphenol polyoxyethylene ether, stir at 1800r / min for 8min to obtain mixture A;

[0025] (2) In the dispersion kettle, add titanium dioxide, guar gum, azodicarbonamide, 1,2-benzisothiazolin-3-one, water-soluble silicone oil and deionized water, at a speed of 3500r / min Stir for 15min to obtain mixture B;

[0026] (3) The mixture ...

Embodiment 3

[0028] An anti-mildew coating for interior walls, made of the following raw materials in parts by weight: 30 parts of butyl acrylate, 25 parts of dibutyl phthalate, 30 parts of elastic emulsion, 20 parts of nonylphenol polyoxyethylene ether, titanium 30 parts of white powder, 20 parts of guar gum, 30 parts of azodicarbonamide, 30 parts of 1,2-benzisothiazolin-3-one, 20 parts of water-soluble silicone oil, and 30 parts of deionized water.

[0029] The preparation method of the anti-mildew coating for interior walls is characterized in that it comprises the following steps:

[0030] (1) In the dispersion kettle, add butyl acrylate, dibutyl phthalate, elastic emulsion and nonylphenol polyoxyethylene ether, stir at 1800r / min for 8min to obtain mixture A;

[0031] (2) In the dispersion kettle, add titanium dioxide, guar gum, azodicarbonamide, 1,2-benzisothiazolin-3-one, water-soluble silicone oil and deionized water, at a speed of 3500r / min Stir for 15min to obtain mixture B;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com