Preparation method for antistatic coating for stainless steel pipe

An antistatic, stainless steel technology, which is applied in coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of bombs, missiles and detonators, such as large safety threats, large specific surface area, high resistance, etc., to improve mechanical strength, Effect of large specific surface area and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method for an antistatic coating for stainless steel pipes, comprising the steps of:

[0024] (1) Modified graphene, nano-metal compounds, and silver-loaded mesoporous SiO 2 Add the microspheres and butanediol into the reaction kettle, and stir for 0.5-1h at a temperature of 50-60°C;

[0025] (2) Add epoxy acrylic resin and catalyst to the reaction kettle of step (1), raise the temperature of the system to 200-220°C, and react for 2-3h;

[0026] (3) Add antioxidant 1010 and stabilizer, then vacuumize for 3-5 hours quickly to obtain antistatic and antibacterial composite functional stainless steel pipe coating;

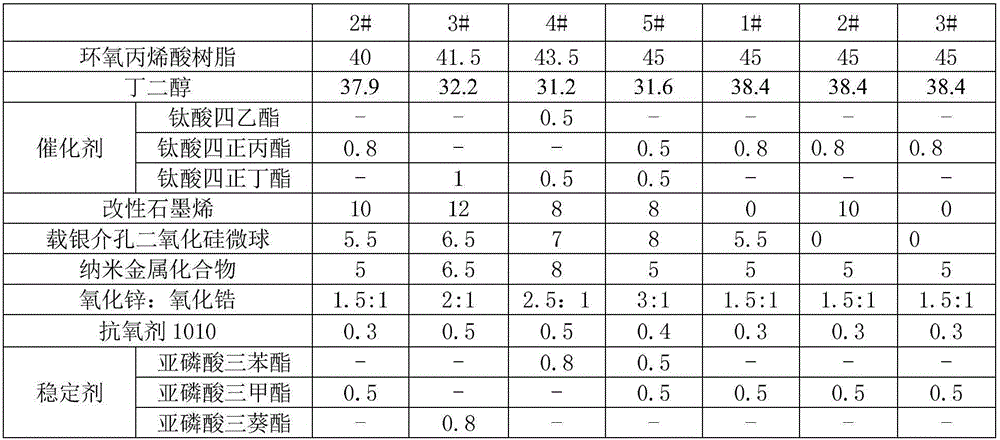

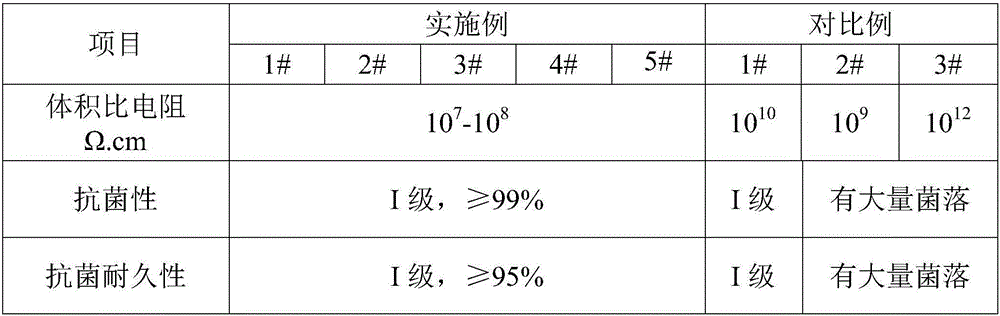

[0027] Wherein each component is in following mass parts, and its composition is as follows:

[0028] 40 parts of epoxy acrylic resin, 43.1 parts of butanediol, 0.5 parts of tetraethyl titanate, 8 parts of modified graphene, 5 parts of silver-loaded mesoporous silica microspheres, zinc oxide with a particle size of 50-100 nm and Zirconia is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com