Water-based polyurethane shoe adhesive with low viscosity and high bonding strength and preparation method thereof

A water-based polyurethane and adhesive technology, applied in the field of water-based polyurethane, can solve the problems of unsatisfactory peel strength, affecting leveling, and increasing the amount of glue, so as to achieve easy recycling, improve stability, and reduce the amount of glue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

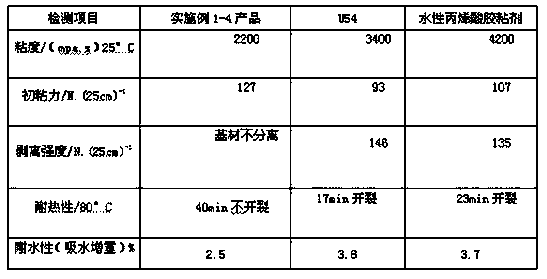

Examples

Embodiment 1

[0031] Add 6 g of sulfonated polyester polyol with a molecular weight of 3000 and 6 g of 1,6-hexanediol adipate with a molecular weight of 2000 into a 500 mL four-necked flask equipped with a thermometer, a stirrer and a reflux condenser, Raise the temperature to about 120°C for dehydration for 30 minutes. After dehydration, cool down to about 80°C. Add 7.5g of 4,4-dicyclomethane diisocyanate, 3g of hexamethylene diisocyanate and 2.5g of trimethylolpropane. Then heat up to 95°C and keep it warm for 3 hours; cool the reaction product to about 60°C and add 2.7g of 1,6 hexanediol, 3g of trimethylpentanediol, 1.8g of dimethylol butyric acid, then heat up to 85°C to expand Chain reaction for 2 hours, after 2 hours of reaction, take samples to measure the content of -NCO in the reactant until it is close to the theoretical value (titration with di-n-butylamine titration method), add 28g of acetone during the reaction to adjust the viscosity, and cool to 40 after the reaction reaches ...

Embodiment 2

[0033] Add 6 g of sulfonated polyester polyol with a molecular weight of 3000 and 6 g of poly(1,6-hexanediol adipate) with a molecular weight of 2000 into a 500 mL four-necked flask equipped with a thermometer, a stirrer and a reflux condenser, and heat up Dehydrate at about 120°C for 30 minutes, after dehydration, cool down to about 80°C, add 1.5g trimethylolpropane and keep it warm for 1 hour, then cool down to about 70°C, add 6g 4,4-dicyclomethane diisocyanate and 4g Hexamethylene diisocyanate, after the addition, heat up to 95°C and keep it warm for 2 hours; cool the reaction product to about 60°C and add 2.5g of 1,6-hexanediol, 2g of trimethylpentanediol, and 1.8g of dimethylol Butyric acid, then heat up to 85°C for chain extension reaction for 2 hours, after 2 hours of reaction, take a sample to measure the content of -NCO in the reactant until it is close to the theoretical value (titration with di-n-butylamine titration), add 28g of acetone during the reaction to adjust...

Embodiment 3

[0035] Add 6 g of sulfonated polyester polyol with a molecular weight of 3,000 and 10 g of poly(1,6-hexanediol adipate) with a molecular weight of 2,000, and 1 g of trimethylolpropane into a 500 mL vessel equipped with a thermometer, a stirrer, and a reflux condenser In a four-neck flask, heat up to about 120 °C for 30 minutes to dehydrate. After dehydration, cool down to about 70 °C, add 4.5g of 4,4-dicyclomethane diisocyanate and 4.5g of hexamethylene diisocyanate, after the addition Heat up to 95°C and keep it warm for 2 hours; cool the reaction product to about 60°C and add 3g of 1,6 hexanediol, 1.5g of trimethylpentanediol, 3g of dimethylol butyric acid, then heat up to 85°C for chain extension reaction 2 hours, after 2 hours of reaction, take a sample to measure the content of -NCO in the reactant until it is close to the theoretical value (titration with di-n-butylamine titration method), add 22g of acetone during the reaction to adjust the viscosity, and cool to 40 °C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com