Steel bonded hard alloy and preparing method thereof

A technology of steel-bonded cemented carbide and a manufacturing method, applied in the field of powder metallurgy, can solve the problems that steel-bonded cemented carbide cannot fully meet market requirements, and achieve the effect of improving hardness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

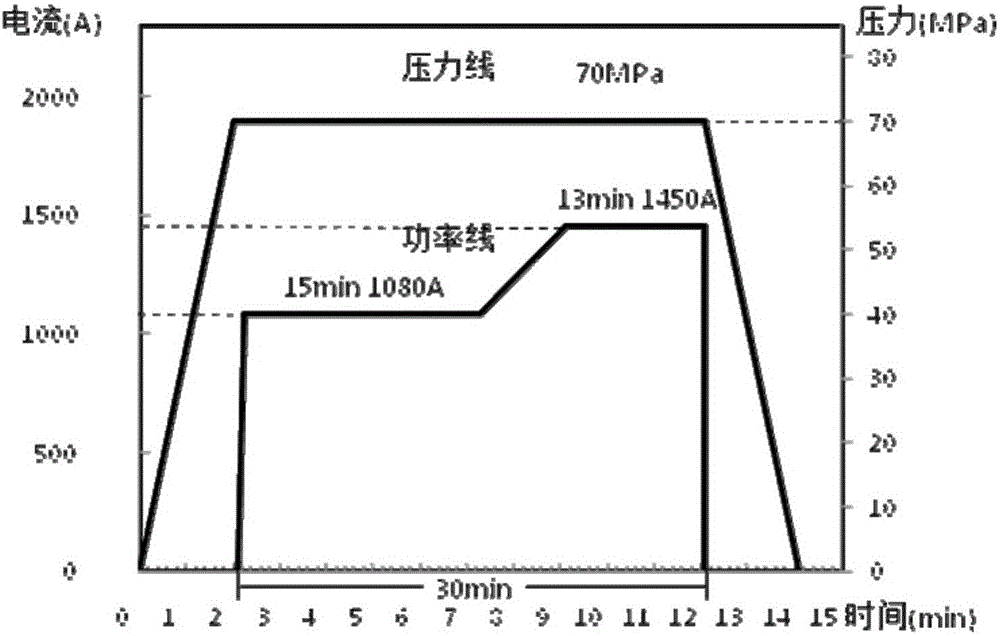

[0028] Weigh 10 kg of 1-micron tungsten carbide powder, 10 kg of 1-micron hydroxyl iron powder, 400 g of liquid paraffin, and 0.2 kg of 1-micron WB(Me), mix the four thoroughly, and place them in the mold with a four-column press Pressed into a columnar shape, dewaxed at 650 degrees and loaded into composite pyrophyllite, and then pressed figure 1 The sintering process line shown is sintered using a six-sided top press. The abscissa in the figure is the time axis, and the ordinate is the qualitative representation of pressure and power. First, raise the pressure line to 70Mpa for 2 minutes, start heating after keeping the pressure for 5 seconds, raise the output current of the heater to 1080 amps in 10 seconds, keep warm for 15 minutes, then slowly increase the current to 1450 amps for 110 seconds, and keep the temperature at 13 The heat supply is stopped within one minute, the power line returns to 0, and then the pressure is released after two minutes, and the pressure line ...

Embodiment 2

[0030] Weigh 10 kg of 1-micron tungsten carbide powder, 10 kg of 1-micron hydroxyl iron powder, 400 g of liquid paraffin, and 0.4 kg of 1-micron WB(Me), mix the four thoroughly, and place them in the mold with a four-column press Press into a columnar shape, put it into composite pyrophyllite after dewaxing at 650 degrees, and use a six-sided top press for sintering. The process is the same as in Example 1. After the pressure is released, take out the steel-bonded cemented carbide test block of the embodiment of the present invention, and test it after quenching and tempering The bending strength of the test block is 3800kg / mm 2 , the compressive strength is 4600kg / mm 2 , hardness HRA93 (corresponding HRC is greater than 70). However, the existing steel-bonded hard alloy has a bending strength of about 1500-1600kg / mm2, a compressive strength of 1600-2000kg / mm2, and a hardness of HRC60-65 (the corresponding HRA is less than 83).

Embodiment 3

[0032] Weigh 10 kg of 0.5 micron tungsten carbide powder, 10 kg of 0.5 micron hydroxy iron powder, 400 g of liquid paraffin, and 0.3 kg of 0.5 micron WB(Me), and mix the four fully, and use a four-column press in the mold Press into a columnar shape, put it into composite pyrophyllite after dewaxing at 650 degrees, and use a six-sided top press for sintering. The process is the same as in Example 1. After the pressure is released, take out the steel-bonded cemented carbide test block of the embodiment of the present invention, and test it after quenching and tempering The bending strength of the test block is 3600kg / mm2, the compressive strength is 4450kg / mm2, and the hardness is HRA93 (the corresponding HRC is greater than 70). However, the existing steel-bonded hard alloy has a bending strength of about 1500-1600kg / mm2, a compressive strength of 1600-2000kg / mm2, and a hardness of HRC60-65 (the corresponding HRA is less than 83).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com