Engineering bamboo nail manufacturing method and engineering bamboo nail processing equipment

A manufacturing method and technology of bamboo nails, which are applied in wood processing, manufacturing tools, machinery and equipment, etc., can solve the problems of reduced performance, rust, low durability of bamboo nails, etc., and achieve increased hardness and toughness, improved durability, Long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

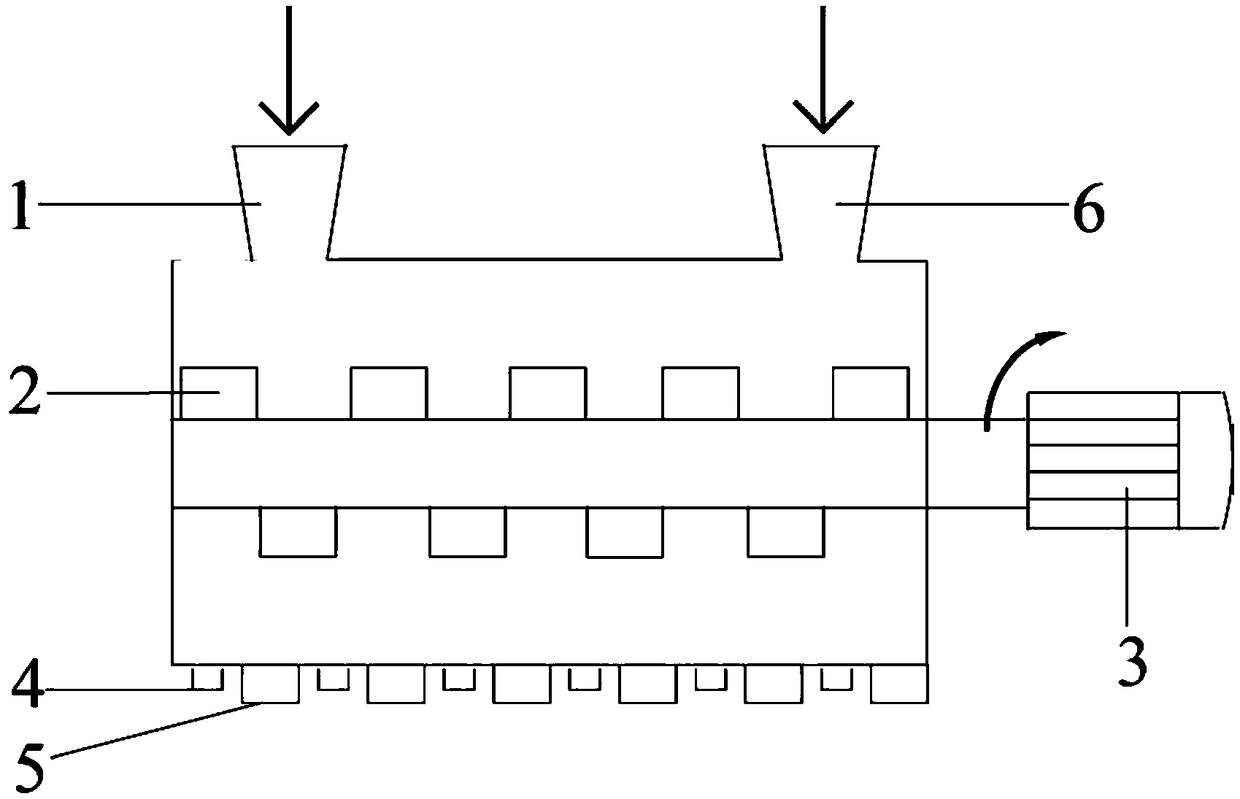

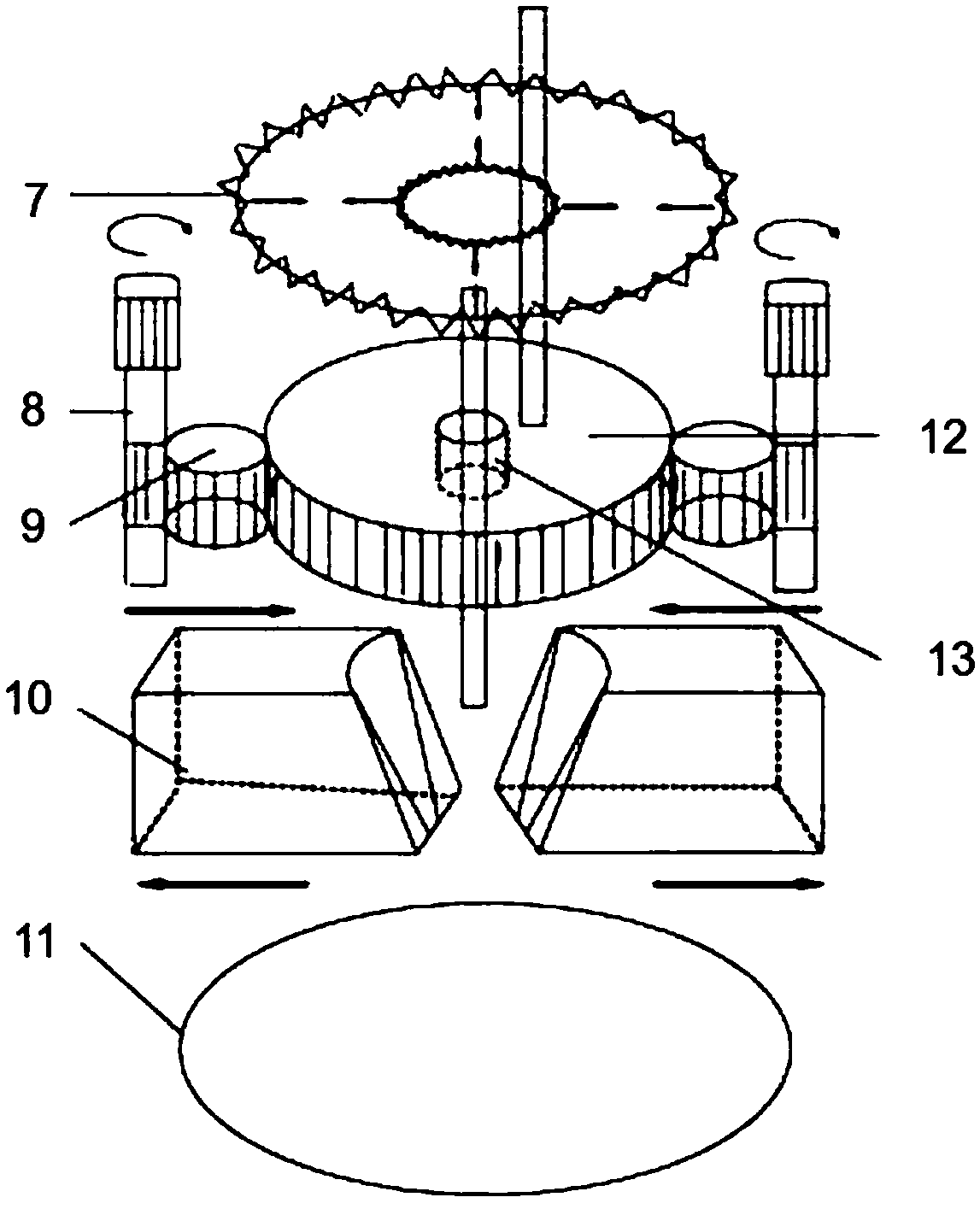

[0030] A kind of manufacturing method of engineering bamboo nail is characterized in that: comprises the following steps:

[0031] Step 1: Bamboo is cut and divided into bamboo slice units, and a round rod-shaped bamboo stick is made by a wire drawing machine. The bamboo is moso bamboo, the thickness of the bamboo wall is 7mm, the width of the split bamboo unit is 6mm, the thickness is 6mm and the length is 2000mm, and the diameter of the round rod-shaped bamboo stick after wire drawing is 5mm.

[0032] In step two, the bamboo sticks obtained in step one are subjected to ultraviolet light treatment and drying treatment.

[0033] UV light intensity is 85W / cm 2 , the wavelength is 260nm, and the treatment time is 40h; drying is carried out in an oven, the drying temperature is 100°C, and the treatment time is 10h.

[0034] Step 3, impregnating the dried bamboo sticks in step 2 with resin, preferably melamine resin. The vacuum-pressure impregnation process is adopted, the vacu...

specific Embodiment 2

[0039] A kind of manufacturing method of engineering bamboo nail is characterized in that: comprises the following steps:

[0040] Step 1: Bamboo is cut and divided into bamboo slice units, and a round rod-shaped bamboo stick is made by a wire drawing machine. The bamboo is Moso bamboo, the thickness of the bamboo wall is 9mm, the width of the split bamboo unit is 8mm, the thickness is 8mm and the length is 2000mm, and the diameter of the round rod-shaped bamboo stick after drawing is 6.5mm.

[0041] In step two, the bamboo sticks obtained in step one are subjected to ultraviolet light treatment and drying treatment.

[0042] UV light intensity is 95W / cm 2 , the wavelength is 260nm, and the processing time is 45h; the drying is carried out in an oven, the drying temperature is 100°C, and the drying time is 11h.

[0043] Step 3, impregnating the dried bamboo sticks in step 2 with resin, preferably melamine resin. The vacuum-pressure impregnation process is adopted, the vacuu...

specific Embodiment 3

[0048] A kind of manufacturing method of engineering bamboo nail is characterized in that: comprises the following steps:

[0049] Step 1: Bamboo is cut and divided into bamboo slice units, and a round rod-shaped bamboo stick is made by a wire drawing machine. The bamboo is moso bamboo, the thickness of the bamboo wall is 11mm, the width of the split bamboo unit is 10mm, the thickness is 10mm and the length is 2000mm, and the diameter of the round rod-shaped bamboo stick after wire drawing is 8mm.

[0050] In step two, the bamboo sticks obtained in step one are subjected to ultraviolet light treatment and drying treatment.

[0051] UV light intensity is 110W / cm 2 , the wavelength is 260nm, and the treatment time is 50h; drying is carried out in an oven, the drying temperature is 100°C, and the drying time is 12h.

[0052] Step 3, impregnating the dried bamboo sticks in step 2 with resin, preferably melamine resin. The vacuum-pressure impregnation process is adopted, the vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com