Production method of grey white monocrystalline fused alumina

A technology of single crystal corundum and production method, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc. It can solve the problems of irregular color change of grinding wheel, affect the appearance of grinding wheel products, and is not easy for users to accept, so as to achieve a clean production environment Neatness, reasonable particle size composition distribution, enhanced hardness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

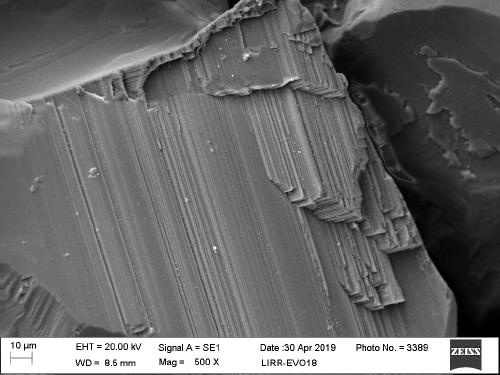

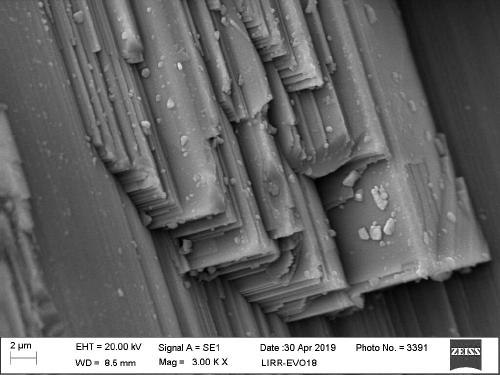

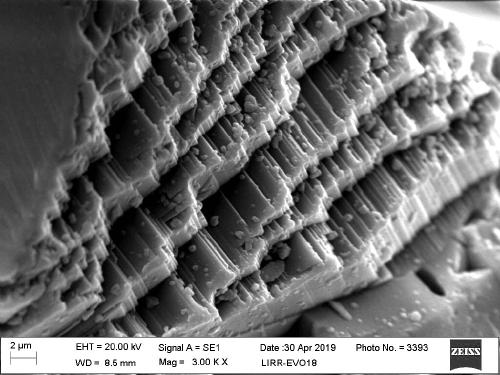

Image

Examples

Embodiment Construction

[0031] A production method of off-white single crystal corundum, comprising the steps of:

[0032] a. Mixing: Mix the raw materials according to the following parts by weight: Al 2 o 3 100 parts, TiO 2 1-5 parts; preferably, TiO 2 for 3 copies;

[0033] b. Smelting: put the mixed raw materials into an electric arc furnace for smelting, heat to 2100°C~2400°C, until the raw materials in the electric arc furnace are fully melted; preferably, heat to 2300°C;

[0034] c. Discharging: After fully melting, pour it into the receiving bag, and keep it warm for 24 hours at room temperature;

[0035] d. Crushing: Break the corundum into small pieces with a hammer, and then crush it with a counterattack;

[0036] e. Magnetic separation and impurity removal: use a magnetic separator to separate the magnetic impurities in the corundum sand;

[0037] f. Screening: Screening by jet mill, and classifying the sieved particles with a sieve of appropriate mesh number;

[0038] g. Secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com