Method for utilizing biological enzyme to conduct continuous and rapid desizing and boiling-off on cellulosic fiber containing textile fabric

A technology of cellulose fibers and textiles, which is applied in the field of pretreatment of cellulose fiber textiles, can solve the problems of cumbersome processing procedures, long processing time, and high temperature requirements, and achieve high product qualification rate, maintain original characteristics, and good The effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

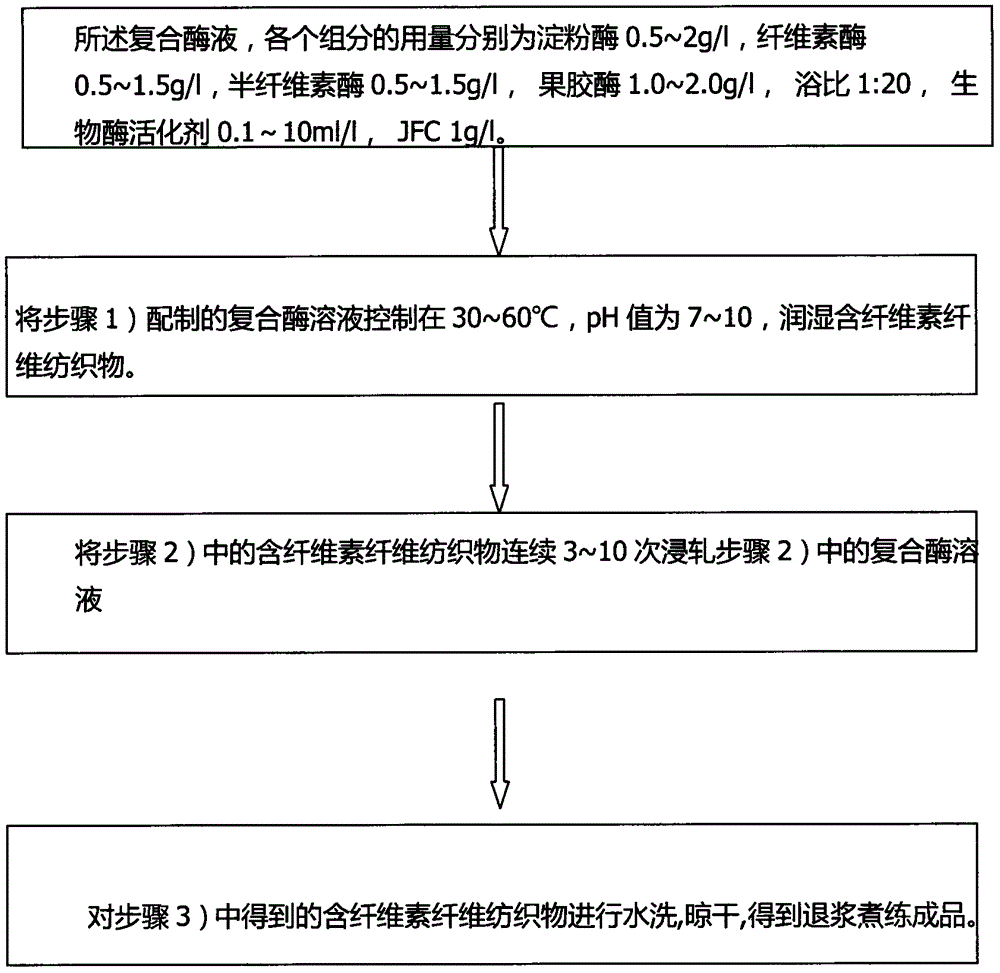

Image

Examples

Embodiment 1

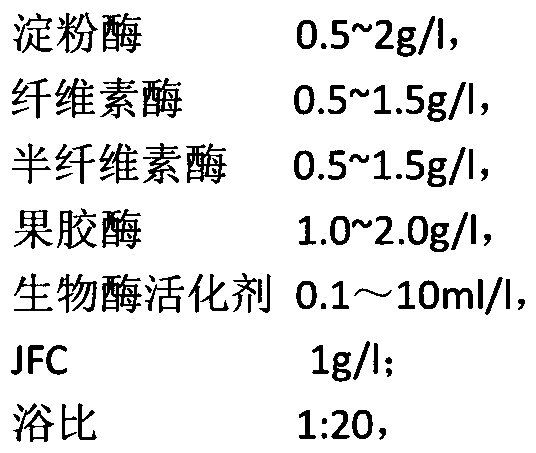

[0029] 1) prepare compound enzyme solution, described compound enzyme solution formula is:

[0030]

[0031] Control the compound enzyme solution prepared in step 1) at 50° C., the pH value is 7, and wet the woven cotton fabric;

[0032] With the woven cotton fabric in step 2) padding the compound enzyme solution in step 2) continuously for 10 times;

[0033] The woven cotton fabric obtained in step 3) is washed with water and dried to obtain a desizing and scouring finished product.

[0034] Process flow chart see figure 1 .

Embodiment 2

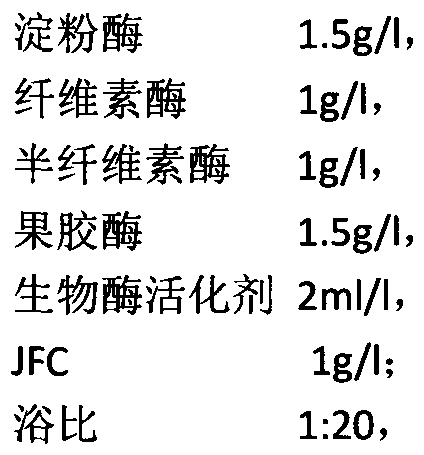

[0036] 1) prepare compound enzyme solution, described compound enzyme formula is:

[0037]

[0038] The complex enzyme solution prepared in step 1) is controlled at 55° C., the pH value is 8, and the knitted cotton fabric is wetted;

[0039] The knitted cotton fabric in step 2) is continuously padded with the compound enzyme solution in step 2) for 8 times;

[0040] The knitted cotton fabric obtained in step 3) is washed with water and dried to obtain a desizing and scouring finished product.

[0041] Process flow chart see figure 1 .

Embodiment 3

[0043] 1) prepare compound enzyme solution, described compound enzyme formula is:

[0044]

[0045]

[0046] The complex enzyme solution prepared in step 1) is controlled at 55° C., the pH value is 7, and the hemp fabric is wetted;

[0047] The hemp fabric in step 2) is continuously padded with the compound enzyme solution in step 2) for 6 times;

[0048] The hemp fabric obtained in step 3) is washed with water and dried to obtain a desizing and scouring finished product.

[0049] Process flow chart see figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com