A back-contact crystalline silicon solar cell, its preparation method, component, and system

A technology for solar cells and crystalline silicon, applied in the field of solar cells, can solve problems such as being difficult to obtain, and achieve the effects of increasing open-circuit voltage and short-circuit current, reducing recombination, and excellent field passivation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

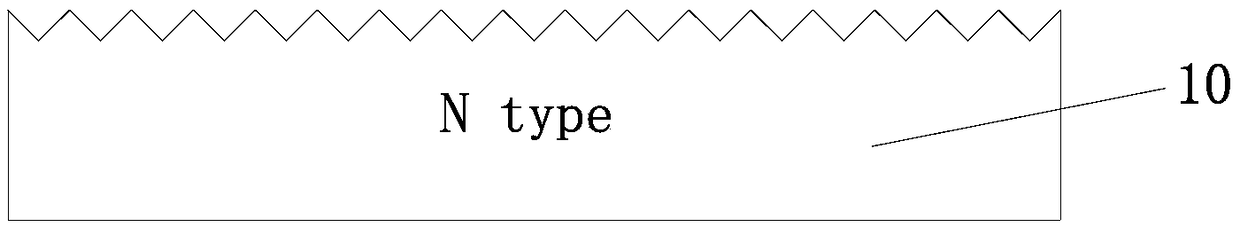

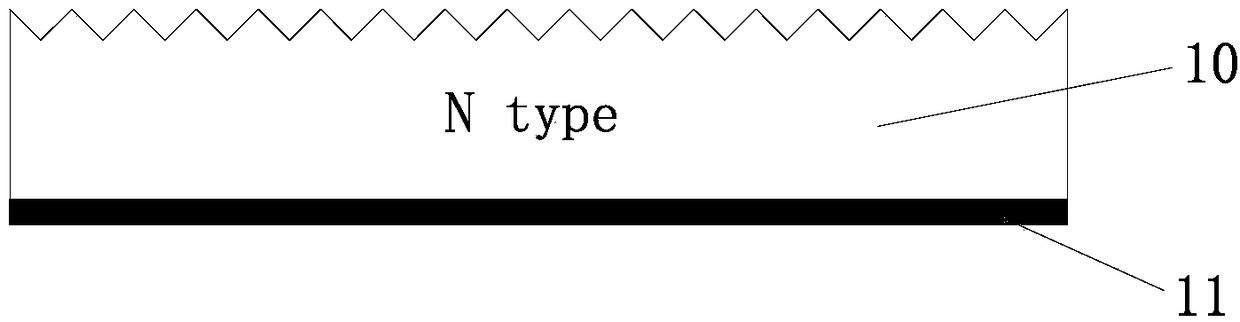

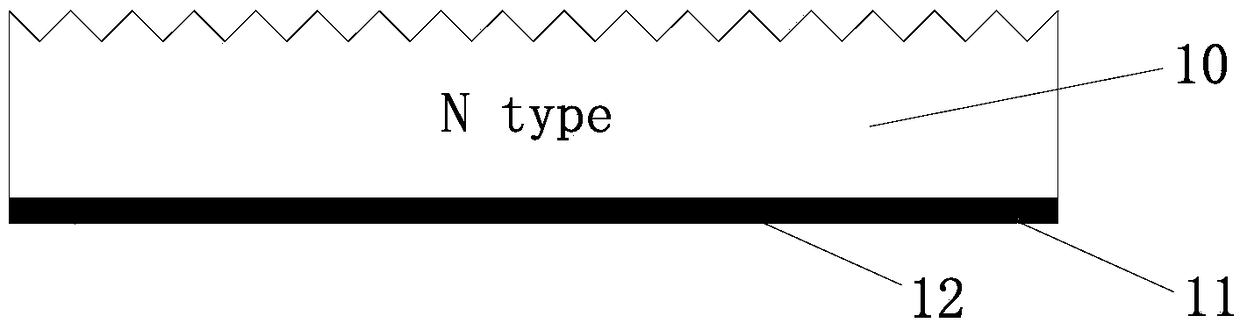

[0036] see Figure 7As shown, a back-contact crystalline silicon solar cell of this embodiment includes an N-type crystalline silicon substrate 10, and the front surface of the N-type crystalline silicon substrate 10 is an oxide layer on the front surface and an n+ doped polysilicon on the front surface. Layer 13 and anti-reflection film on the front surface; the back surface of the N-type crystalline silicon substrate 10 is sequentially composed of doped regions, passivation films on the back surface, and metal electrodes in ohmic contact with the doped regions, and the doped regions include alternately The back surface n+ doped region 12 and the back surface p+ doped region 11 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com