Preparation method of Pr(OH)3 one-dimensional nano-rods

A nanorod and electroplating technology, applied in the field of Pr3 one-dimensional nanorod preparation, can solve the problem that the large-scale production of supercapacitor anode materials is limited to carbon-based materials, achieve excellent capacitance performance, increase specific surface area, and increase capacitance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

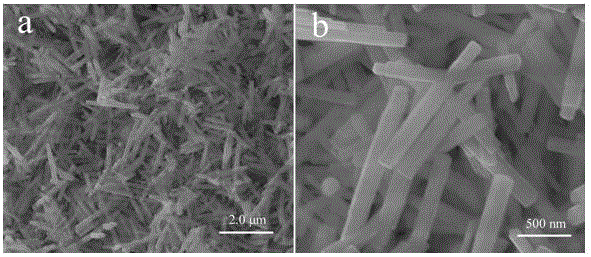

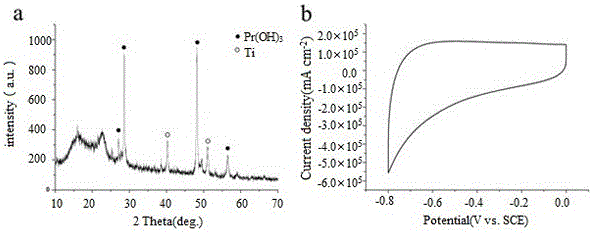

[0025] Pr(OH) 3 The synthesis of nanorods on titanium sheets was achieved by the galvanostatic method. Before the current loading by galvanostatic method, the titanium sheet (1.5 cm × 3 cm) was ultrasonically cleaned in deionized water, ethanol, acetone, and deionized water for 10 minutes respectively, and then dried with compressed air for later use. Dip the cleaned titanium sheet into a two-electrode system containing 20 ml of a precursor aqueous solution mixed with praseodymium nitrate and ammonium nitrate, which corresponds to 90 mg of praseodymium nitrate hexahydrate and 30 mg of ammonium nitrate. A titanium sheet was used as the working electrode and a platinum electrode was used as the counter electrode, and the two-electrode system was placed in an oil bath at 70 °C. After the system temperature stabilized, a negative 2.0 mA loading current was applied to the system and the reaction was kept for 2 h. After the reaction, the titanium sheet was taken out, and the obtai...

Embodiment 2~5

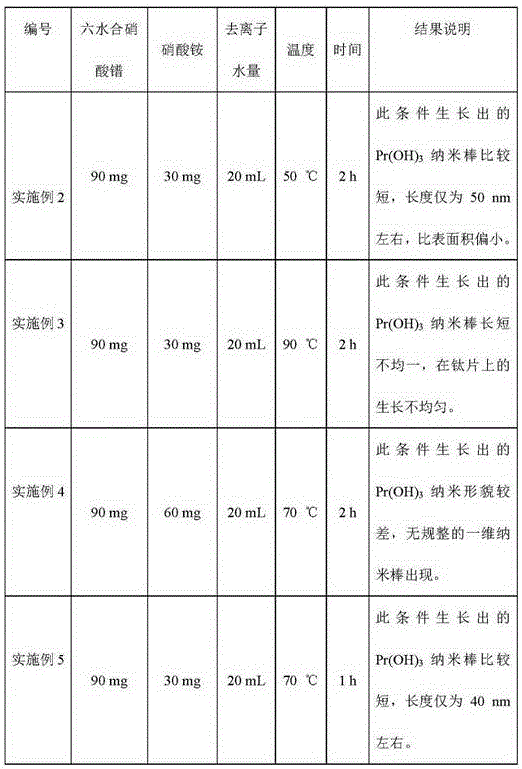

[0028] Based on the scheme of Example 1, by regulating and controlling different reaction conditions, the influence of Pr(OH) 3 growth, and its relationship is shown in Table 1.

[0029] Among them, Examples 2 and 3 show that the temperature factor has a great influence on the material preparation, Example 4 shows that the mixing ratio of the precursor solution affects the material preparation, and Example 5 shows that the reaction time factor will restrict the growth length of the material. Described embodiment 2~5 all can prepare Pr(OH) 3 material, but relatively speaking, the appearance is poor, the specific surface area is small, the reactive active sites are few, and the supercapacitive performance is not as good as that of Example 1.

[0030] Table 1. Pr(OH) 3 Growth regulation of nanorods

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com