Method for preparing medium chrome yellow from bichromate or chromate

A technology of dichromate and chromate is applied in the preparation of chromate/dichromate, alkali metal nitrate, etc., and achieves the effects of easy large-scale promotion, simple reaction system and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

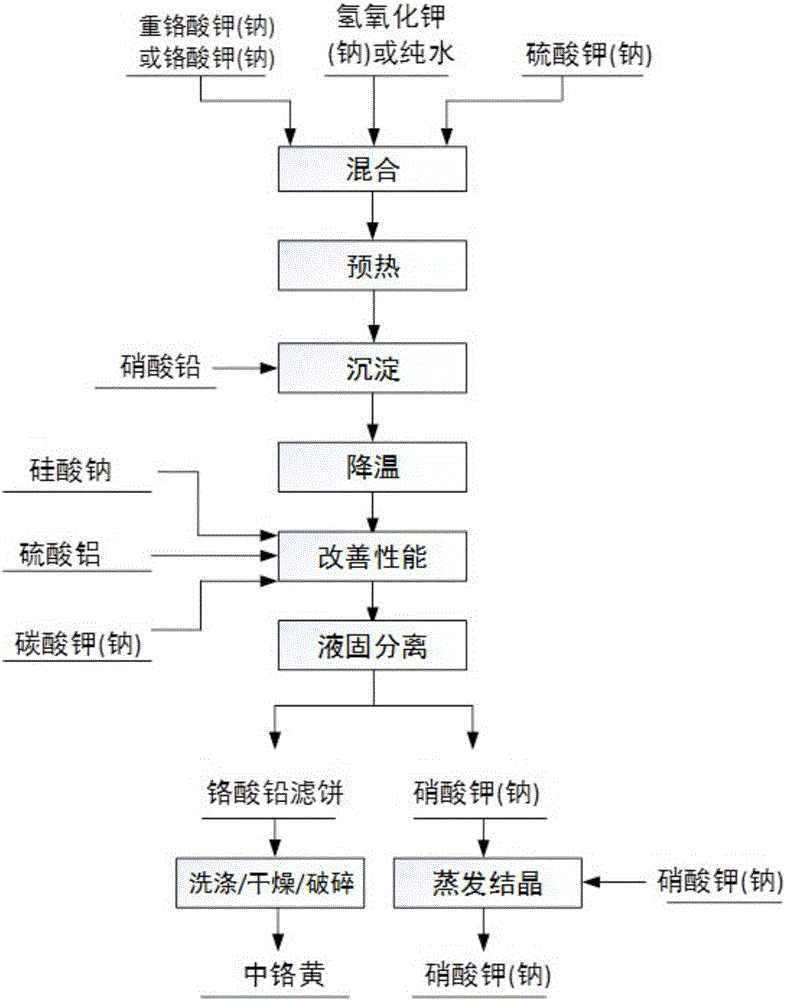

[0034] The method for preparing medium chrome yellow as raw material with dichromate of the present embodiment is as figure 1 As shown, it proceeds in the following steps:

[0035] 1. Weigh 390g of potassium dichromate and 120g of sodium sulfate and add it into a 38% sodium hydroxide solution to adjust the pH to 8, then dilute to 4400mL;

[0036] Two, according to the amount of potassium dichromate in the step one, calculate the amount of required lead nitrate of complete reaction potassium dichromate, and take lead nitrate and be mixed with concentration and be 35% lead nitrate solution;

[0037] 3. Put the mixed solution obtained in step 1 into the preheating tank to preheat to 90°C;

[0038] 4. Add the lead nitrate solution prepared in step 2 to the preheated mixed solution in step 3. After standing for 20 minutes, cool to 90° C. to prepare a mixed slurry;

[0039] 5. Add 110 g of sodium silicate and 72 g of aluminum sulfate in turn to the mixed slurry prepared in step 4....

Embodiment 2

[0042] The method for preparing medium chrome yellow as raw material with dichromate of the present embodiment is as figure 1 As shown, it proceeds in the following steps:

[0043] 1. Weigh 300g of sodium dichromate and 135g of potassium sulfate and add it into a 40% sodium hydroxide solution to adjust the pH to 10, then dilute to 4300mL;

[0044] Two, according to the amount of sodium dichromate in step one, calculate the amount of required lead nitrate of complete reaction sodium dichromate, and take lead nitrate and be mixed with concentration and be 30% lead nitrate solution;

[0045] 3. Put the mixed solution obtained in step 1 into the preheating tank to preheat to 100°C;

[0046] 4. Add the lead nitrate solution prepared in step 2 to the preheated mixed solution in step 3, and after standing for 40 minutes, cool to 60° C. to obtain a mixed slurry;

[0047] 5. Add 118g of sodium silicate and 80g of aluminum sulfate successively into the mixed slurry obtained in step 4....

Embodiment 3

[0050] The method for preparing medium chrome yellow as raw material with dichromate of the present embodiment is as figure 1 As shown, it proceeds in the following steps:

[0051] 1. Weigh 480g of potassium dichromate and 130g of potassium sulfate and add it into a 20% potassium hydroxide solution to adjust the pH to 8.5, then dilute to 4800mL;

[0052] Two, according to the amount of potassium dichromate in the step one, calculate the amount of required lead nitrate of complete reaction potassium dichromate, and take lead nitrate and be mixed with concentration and be 45% lead nitrate solution;

[0053] 3. Put the mixed solution obtained in step 1 into the preheating tank to preheat to 70°C;

[0054]4. Add the lead nitrate solution prepared in step 2 to the preheated mixed solution in step 3. After standing for 23 minutes, cool to 70° C. to obtain a mixed slurry;

[0055] 5. Add 124g of sodium silicate and 78g of aluminum sulfate to the mixed slurry prepared in step 4. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com