A kind of preparation method of inner protective coating for oil casing storage

An internal protection, oil casing technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effect of improving impermeability, good resistance reduction effect, and good alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

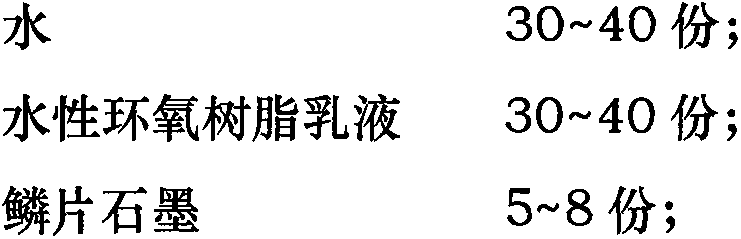

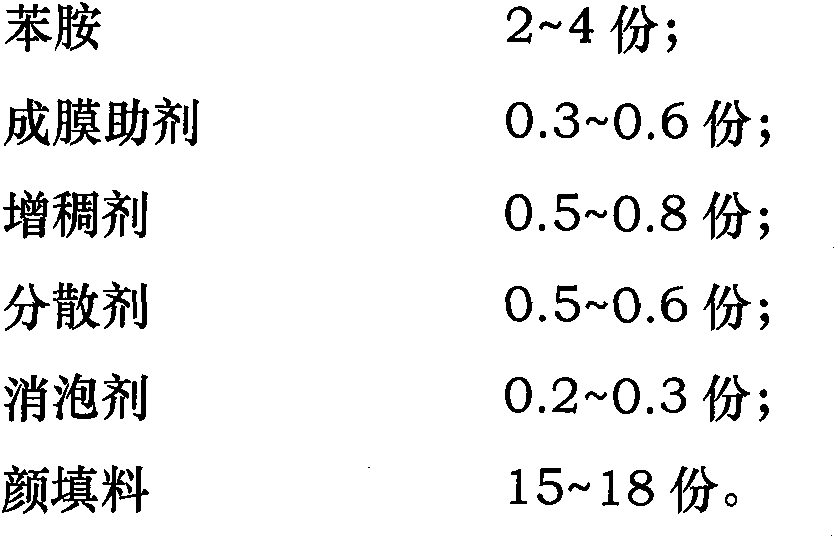

[0034] Example 1: A kind of internal protective coating for oil casing storage

[0035] The main formula includes: 36.1 parts of water; 36.1 parts of water-based epoxy resin emulsion; 6.1 parts of flake graphite; 3.2 parts of aniline; 0.45 parts of film-forming aid; 0.65 parts of thickener; 16.5 servings.

Embodiment 2

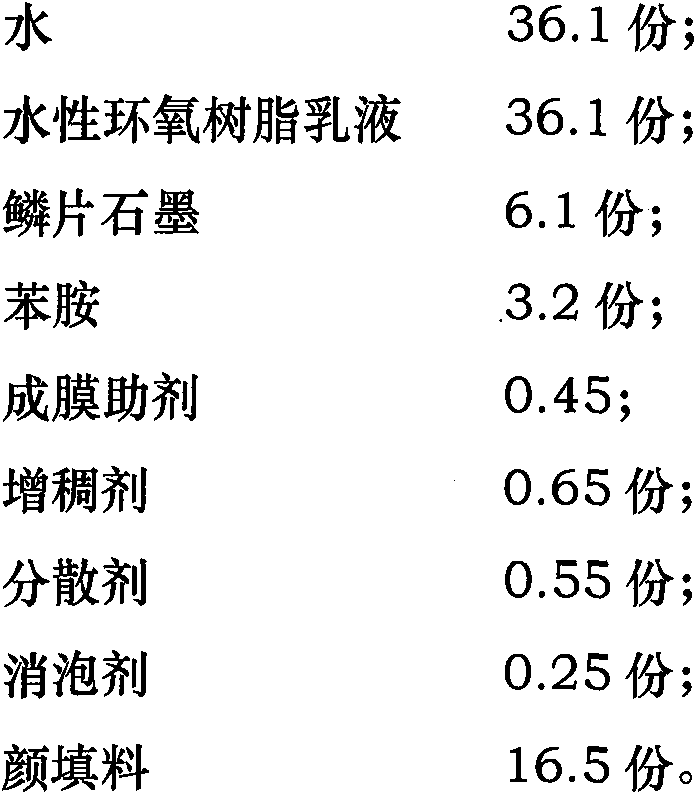

[0036] Example 2: An inner protective coating for oil casing storage

[0037] The main formula includes: 37 parts of water; 34 parts of water-based epoxy resin emulsion; 7 parts of flake graphite; 4 parts of aniline; 0.4 part of film-forming aid; 0.7 part of thickener; 15.8 servings.

Embodiment 3

[0038] Embodiment 3: A method for preparing an inner protective coating for storage of oil and casing according to the embodiment, comprising the following steps:

[0039] 1) Emulsification of epoxy resin

[0040] After heating 300g of epoxy resin in a water bath at 70°C for 20min, put it into an ultrasonic instrument, add 12.6g of octylphenol polyoxyethylene (10) ether, polyoxyethylene ether under the action of a 6000r / min high-shear mixing emulsifier 0.21g of sorbitan monolaurate, 6.3g of sodium lauryl sulfate and 15ml of propylene glycol methyl ether, the selection and proportioning of the emulsifier in the above ratio have a good emulsification effect, and the stability of the emulsion after emulsification is better, After reacting for 5 minutes, keep the temperature at 70°C and add hot water at 80°C dropwise, and continue to perform 6000r / min high-speed shearing for 10 minutes, then add the remaining water dropwise, the total amount of water added is 170ml, and the method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com