Automobile turbocharger shell and preparation method thereof

A turbocharger and casing technology, which is applied in mechanical equipment, machines/engines, engine components, etc., can solve the problem of very high internal quality and internal porosity requirements of products, unable to meet the porosity requirements of auto parts, low density, etc. problems, to achieve the effect of good market prospects, accurate design, and lightweight materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

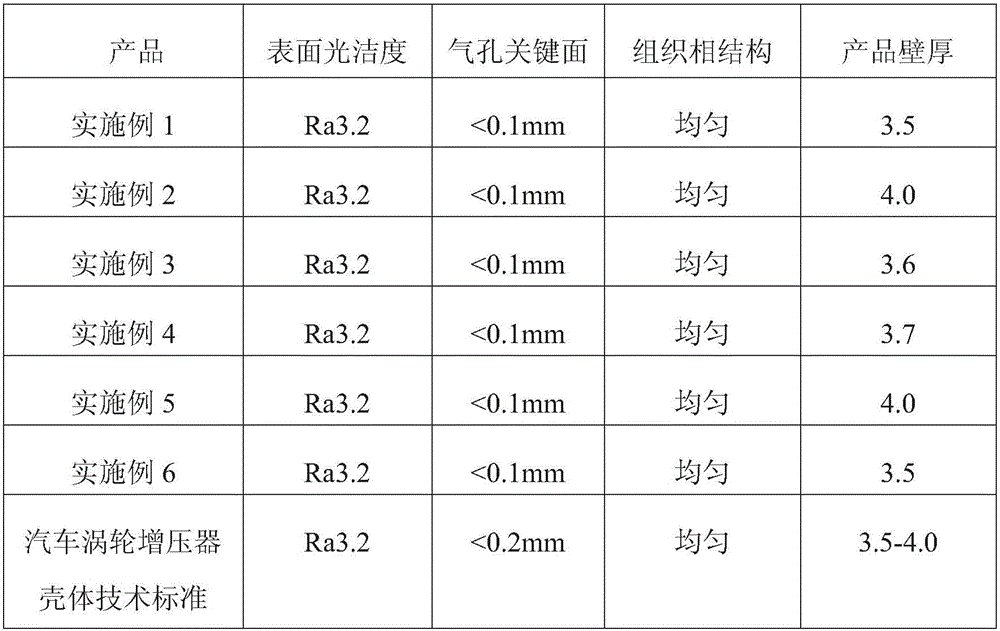

Examples

Embodiment 1

[0028] An automobile turbocharger housing, composed of the following components by weight: 9% silicon, 1.3% iron, 4.0% copper, 0.55% magnesium, 1.1% zinc, 0.10% chromium, 0.35% nickel, 0.25% tin , 0.25% titanium, 0.35% lead, 0.55% manganese, and the balance is aluminum.

[0029] The smelting furnace is heated to above 600°C, and silicon, iron, copper, magnesium, zinc, chromium, nickel, tin, titanium, lead, manganese and aluminum are added into the furnace according to the above-mentioned weight ratio. Continue to heat the above mixed material, and when the temperature of the mixed material rises to 720°C±10°C, add a two-in-one refining agent with an amount of 0.1%-0.8% of the mixed material for refining, and use a bell jar to press the refining agent into the mixed material Perform circular stirring in the liquid for 5-15 minutes, use 99.99% argon for degassing operation for 3-15 minutes, and stand still for 10-15 minutes to prepare for die-casting; Preheat the mold to 160-25...

Embodiment 2

[0034]In this embodiment, the automobile turbocharger housing is composed of the following components in weight percentage: 8.5% silicon, 0.5% iron, 2.5% copper, 0.10% magnesium, 1.0% zinc, 0.05% chromium, and 0.05% nickel , 0.10% tin, 0.15% titanium, 0.15% lead, 0.2% manganese, and the balance is aluminum.

[0035] The above-mentioned automobile turbocharger housing is obtained by the same method as in Example 1.

[0036] Compared with the existing thin-walled turbocharger shell products, the turbocharger shell product prepared in this embodiment has a uniform structure and low porosity, meets the technical requirements of pores <0.2mm, and has high endurance and quality. lighter.

Embodiment 3

[0038] In this embodiment, the automobile turbocharger housing is composed of the following components in weight percentage: 10.5% silicon, 1.3% iron, 4.0% copper, 0.55% magnesium, 1.2% zinc, 0.15% chromium, and 0.55% nickel , 0.25% tin, 0.25% titanium, 0.35% lead, 0.55% manganese, and the balance is aluminum.

[0039] The above-mentioned automobile turbocharger housing is obtained by the same method as in Example 1.

[0040] Compared with the existing thin-walled turbocharger shell products, the turbocharger shell product prepared in this embodiment has a uniform structure and low porosity, meets the technical requirements of pores <0.2mm, and has high endurance and quality. lighter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com