Shape memory alloy micro valve based on acoustic surface waves and control method of shape memory alloy micro valve

A technology of memory alloy and surface acoustic wave, which is applied to valve devices, engine components, mechanical equipment, etc., can solve problems such as difficult circuits, difficult application of piezoelectric microfluidic devices, and high current of aluminum wires, and achieves simple structure and small volume , easy-to-integrate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

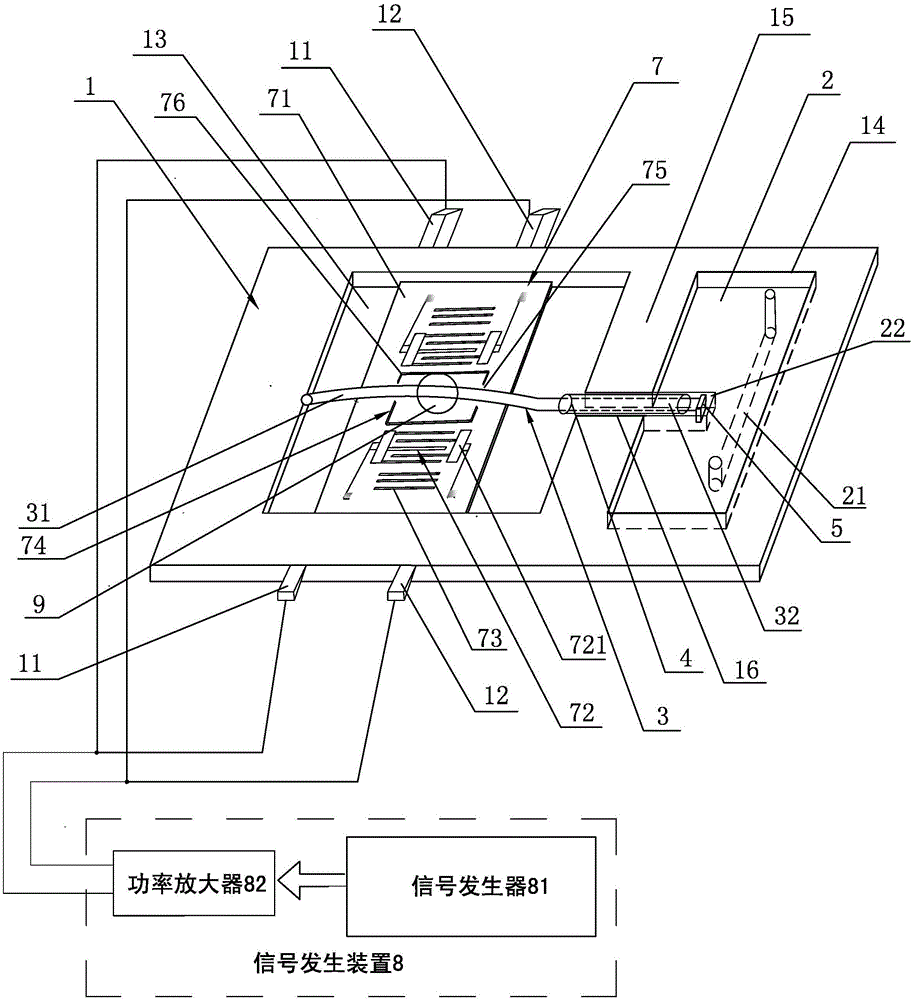

[0036] A kind of shape memory alloy microvalve based on surface acoustic wave proposed in this embodiment, such as figure 1 As shown, it includes a PCB board 1, a surface acoustic wave excitation device 7, a PDMS solidified body 2 with a microchannel 21, a shape memory alloy wire 3, and the shape memory alloy wire 3 is a first section that is slightly bent at room temperature made of one piece The shape memory alloy wire 31 is composed of the second straight shape memory alloy wire 32 at room temperature, the surface acoustic wave excitation device 7 and the PDMS solidified body 2 are installed on the PCB board 1, and one side of the PDMS solidified body 2 is provided with a Groove 22, the other end of the first section of shape memory alloy wire 31 is connected to the PCB board 1, the first section of shape memory alloy wire 31 is across the propagation path of the surface acoustic wave excited by the surface acoustic wave excitation device 7, and the second A section of shap...

Embodiment 2

[0047] This embodiment proposes the control method of the SAW-based shape memory alloy microvalve of Embodiment 1, which includes the following steps:

[0048] ① Place the paraffin oil micro-liquid on the propagation path of the surface acoustic wave excited by the surface acoustic wave excitation device.

[0049] ② When the signal generator and power amplifier are not activated, and the surface acoustic wave excitation device does not excite the surface acoustic wave, the shape memory alloy microvalve is in the open state, and the digital microfluidics can pass through the PDMS solidified body under the action of the external sampler. Transport in microchannels;

[0050] The control process of the shape memory alloy microvalve from the open state to the closed state is: start the signal generator and the power amplifier; the signal generator outputs the RF electric signal, and transmits the RF electric signal to the power amplifier; the amplified RF electric signal output by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com