Process of Alkylation Spent Acid Treatment Using Sulfur Plant

A technology of alkylation waste acid and sulfur plant, which is applied in the direction of sulfur preparation/purification, etc., which can solve the problems of prolonging the operation period of the catalyst and the difficulty in the treatment of waste acid in the alkylation plant, so as to eliminate the influence of carbon deposits on the catalyst, Effect of high Claus catalytic activity and improvement of Claus conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present invention utilizes sulfur device to process the technology of alkylation waste acid specifically as follows:

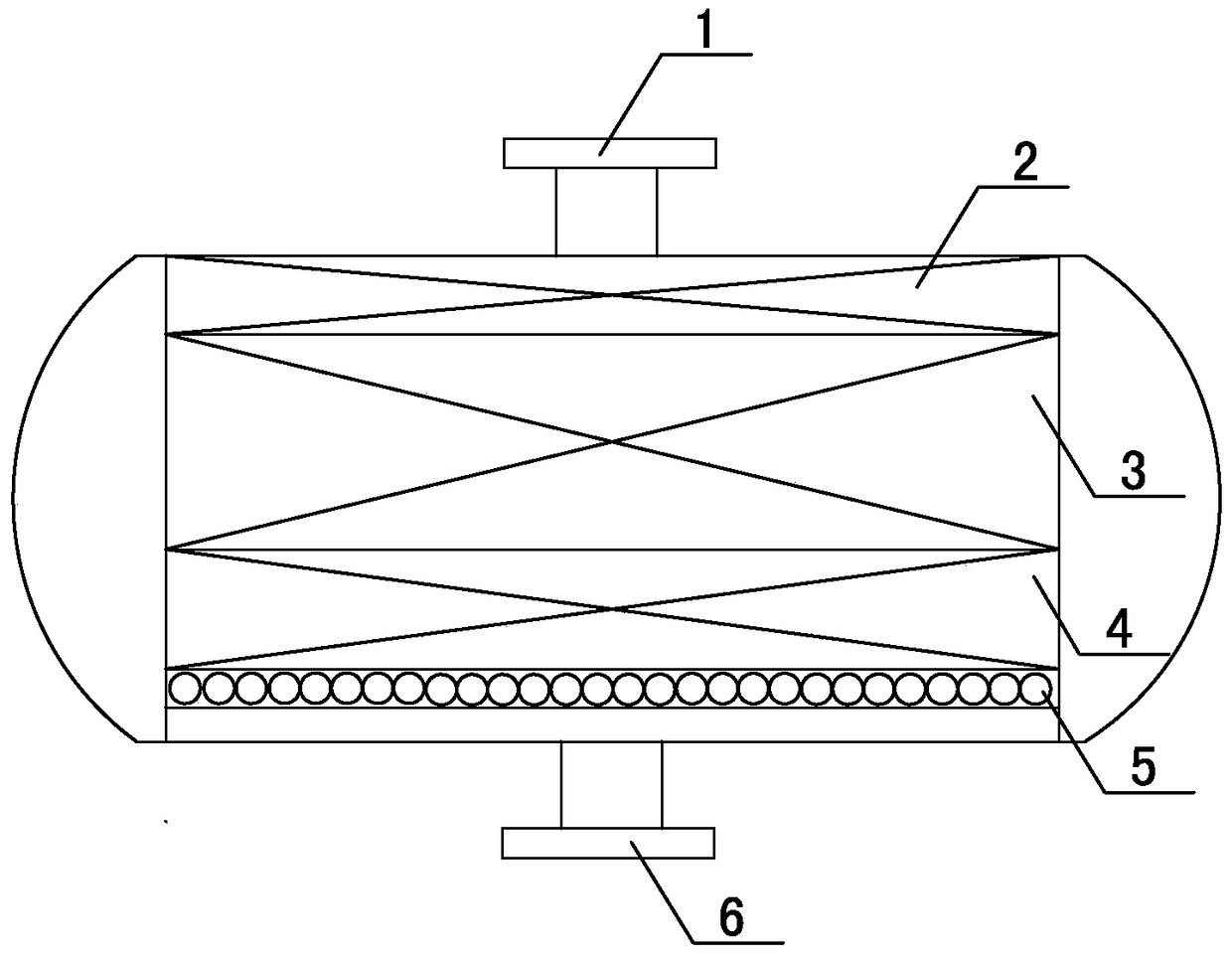

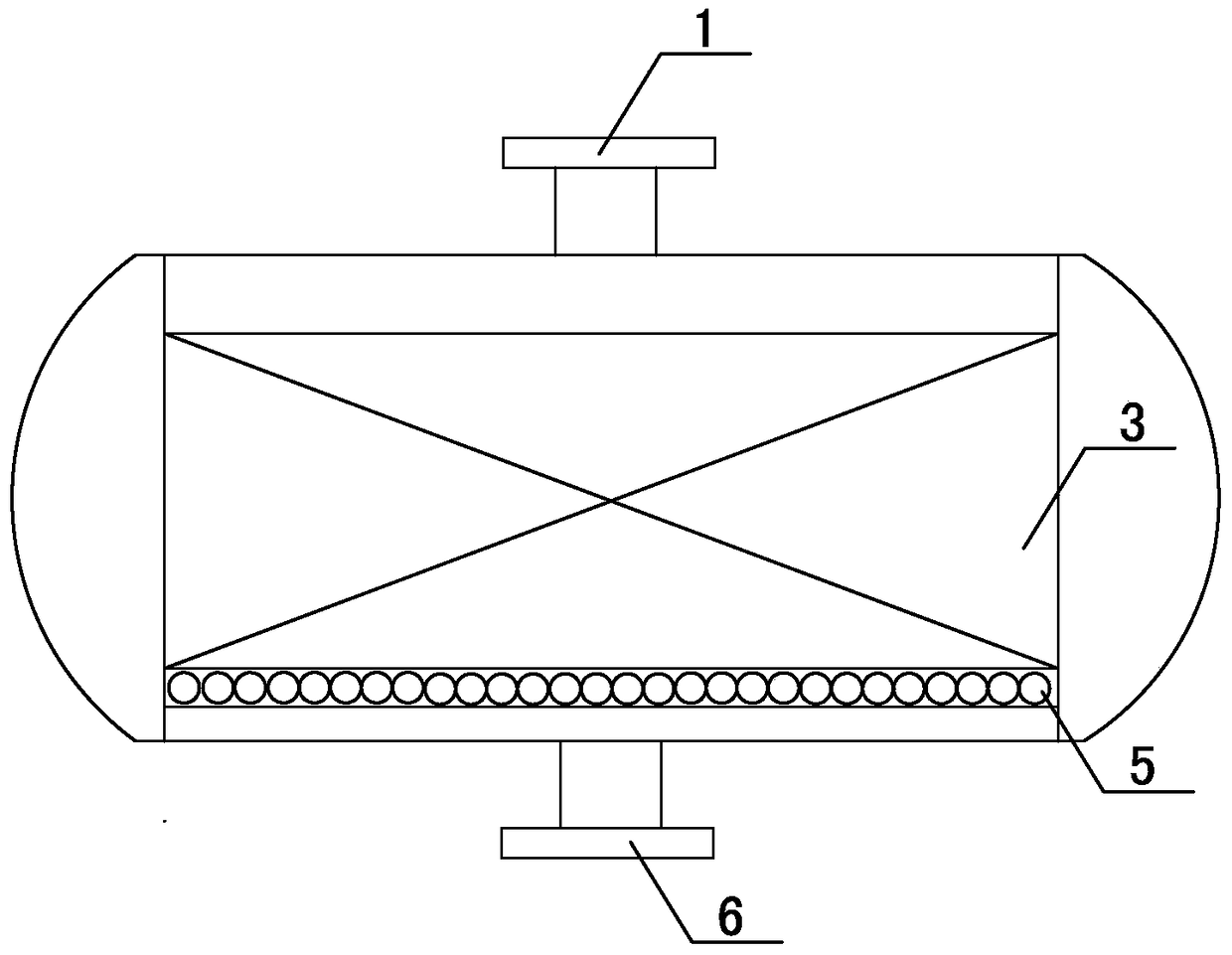

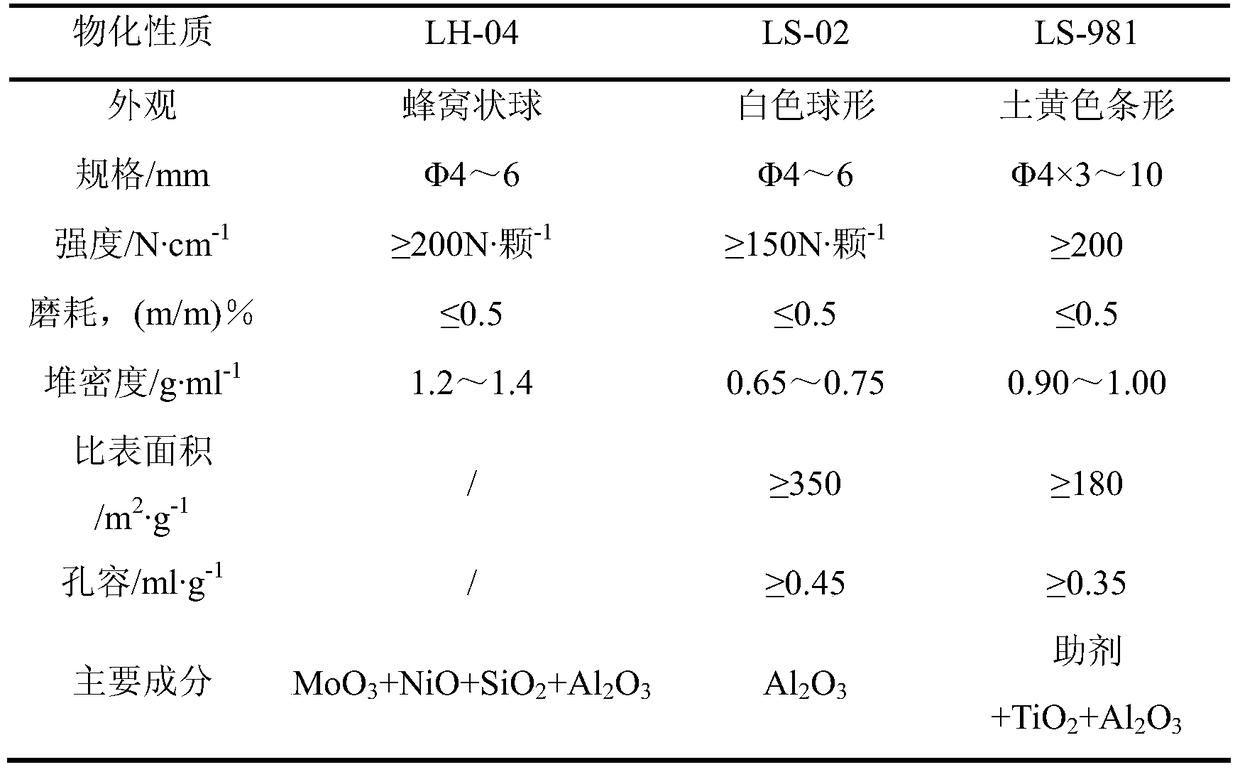

[0057] The upper part of the primary converter is filled with 15% catalytic protector, the middle part is filled with 60% large pore volume and large pore diameter alumina-based sulfur recovery catalyst, and the bottom is filled with 25% multifunctional sulfur recovery catalyst. For details, see figure 1 ; The secondary converters are all filled with large pore volume and large pore diameter alumina-based sulfur recovery catalysts, see figure 2 . The catalytic protector adopts the LH-04 catalytic protector developed by the Research Institute of Sinopec Qilu Branch, the large pore volume and large pore size alumina-based sulfur recovery catalyst adopts the LS-02 catalyst developed by the Research Institute of Sinopec Qilu Branch, and the multifunctional sulfur recovery catalyst adopts The LS-981 catalyst developed by the Research Institute of Sinop...

Embodiment 2

[0059] The present invention utilizes sulfur device to process the technology of alkylation waste acid specifically as follows:

[0060] The upper part of the primary converter is filled with 10% catalytic protector, the middle part is filled with 50% large pore volume and large pore diameter alumina-based sulfur recovery catalyst, and the bottom is filled with 40% multifunctional sulfur recovery catalyst. For details, see figure 1 ; The secondary converters are all filled with large pore volume and large pore diameter alumina-based sulfur recovery catalysts, see figure 2 . The catalytic protector adopts the LH-04 catalytic protector developed by the Research Institute of Sinopec Qilu Branch, the large pore volume and large pore size alumina-based sulfur recovery catalyst adopts the LS-02 catalyst developed by the Research Institute of Sinopec Qilu Branch, and the multifunctional sulfur recovery catalyst adopts The LS-981 catalyst developed by the Research Institute of Sinop...

Embodiment 3

[0062] The present invention utilizes sulfur device to process the technology of alkylation waste acid specifically as follows:

[0063] The upper part of the primary converter is filled with 5% catalytic protector, the middle part is filled with 90% large pore volume and large pore diameter alumina-based sulfur recovery catalyst, and the bottom is filled with 5% multifunctional sulfur recovery catalyst. For details, see figure 1 ; The secondary converter is filled with a large pore volume and large pore size alumina-based sulfur recovery catalyst, see figure 2 . The catalytic protector adopts the LH-04 catalytic protector developed by the Research Institute of Sinopec Qilu Branch, the large pore volume and large pore size alumina-based sulfur recovery catalyst adopts the LS-02 catalyst developed by the Research Institute of Sinopec Qilu Branch, and the multifunctional sulfur recovery catalyst adopts The LS-981 catalyst developed by the Research Institute of Sinopec Qilu Bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com