Carbamazepine dispersible tablet preparation method

A technology of dispersible tablets and carbamazepine, which is applied in the field of preparation of carbamazepine dispersible tablets, can solve the problems of easy energy consumption, unfavorable large-scale production, cumbersome process, etc., and achieve the goal of reducing process steps, reducing input costs, and increasing dissolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

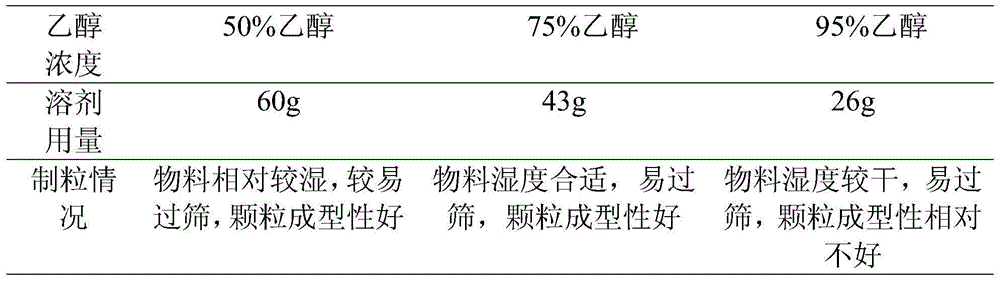

[0025] The selection test of embodiment 1 carbamazepine dissolving solvent

[0026] Take about 20 mg of the raw materials and put them in a beaker, gradually add ethanol solutions of different concentrations (50%, 75%, 95%), observe while shaking until the solution is clear, and weigh the amount of solvent added. According to the amount of different ethanol concentrations, 180 mg of mixed auxiliary materials were used to make soft materials, and the humidity of the soft materials was observed, and sieved with a 20-mesh sieve. The results are shown in Table 1.

[0027] Table 1 The selection and investigation results of the main ingredient dissolving solvent

[0028]

[0029] Results: The above-mentioned ethanol solutions with different concentrations can dissolve 20mg of raw materials well under a certain amount, have a good wetting effect on 180mg, and have good formability on material particles. It is determined that 50-95% ethanol is used as the granulation solvent for th...

experiment example 2

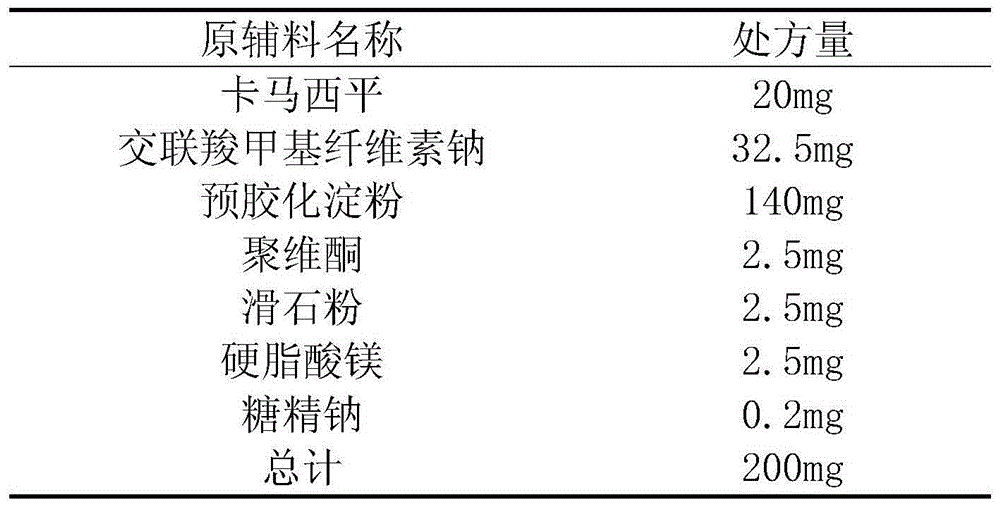

[0031] The prescription of carbamazepine tablets consists of the ingredients shown in Table 2.

[0032] Table 2 Prescription of Carbamazepine Tablets

[0033]

[0034] The preparation method of above-mentioned carbamazepine dispersible tablet is as follows:

[0035] Preparation Process:

[0036] 1. The carbamazepine of recipe quantity, povidone are ultrasonically dissolved in the 75% ethanol solution of about 60g simultaneously, as the binding agent containing principal agent, this binding agent is colorless and transparent, without agglomerate and bubble.

[0037] 2. Take the prescribed amount of sodium carboxymethyl starch, pregelatinized starch, talcum powder, and sodium saccharin and mix them through a 100-mesh sieve for 3 times.

[0038] 3. Add the binder containing the main ingredient to the mixture in step 2, prepare the soft material and granulate it with a 20-mesh sieve, and dry it in an oven at 60°C.

[0039] 4. The granules are passed through a 24-mesh sieve f...

experiment example 3

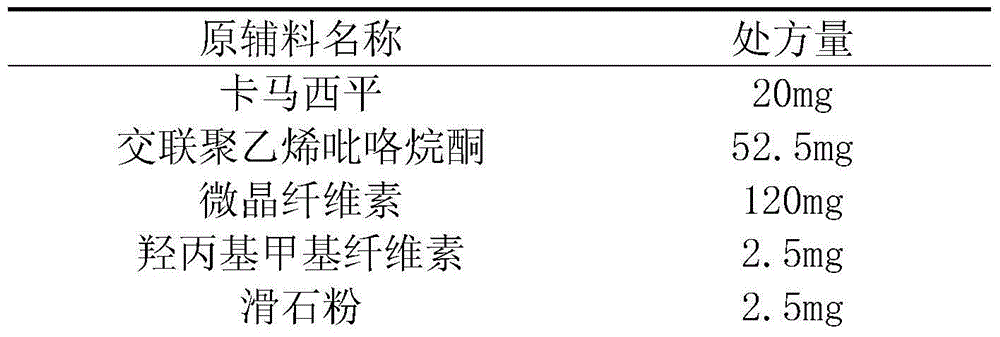

[0042] The prescription of carbamazepine tablets consists of the ingredients shown in Table 3.

[0043] Table 3 Prescription of Carbamazepine Tablets

[0044]

[0045]

[0046] The preparation method of above-mentioned carbamazepine dispersible tablet is as follows:

[0047] Preparation Process:

[0048] 1. Dissolve the prescribed amount of carbamazepine and hydroxypropyl methylcellulose in about 60g of 50% ethanol solution at the same time, and use it as a binder containing the main drug. The binder is colorless and transparent without lumps Blocks and bubbles.

[0049] 2. Take the prescribed amount of microcrystalline cellulose, cross-linked polyvinylpyrrolidone, talcum powder, and aspartame and mix them through a 100-mesh sieve for 3 times.

[0050] 3. Add the binder containing the main ingredient to the mixture in step 2, prepare the soft material and granulate it with a 20-mesh sieve, and dry it in an oven at 40°C.

[0051] 4. The granules are passed through a 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com