Preparation method of DA-based gradient functional material

A gradient functional material, dopamine-based technology, used in medical science, tissue regeneration, prosthesis, etc., to achieve the effect of promoting bone tissue regeneration performance, excellent cell adhesion, and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

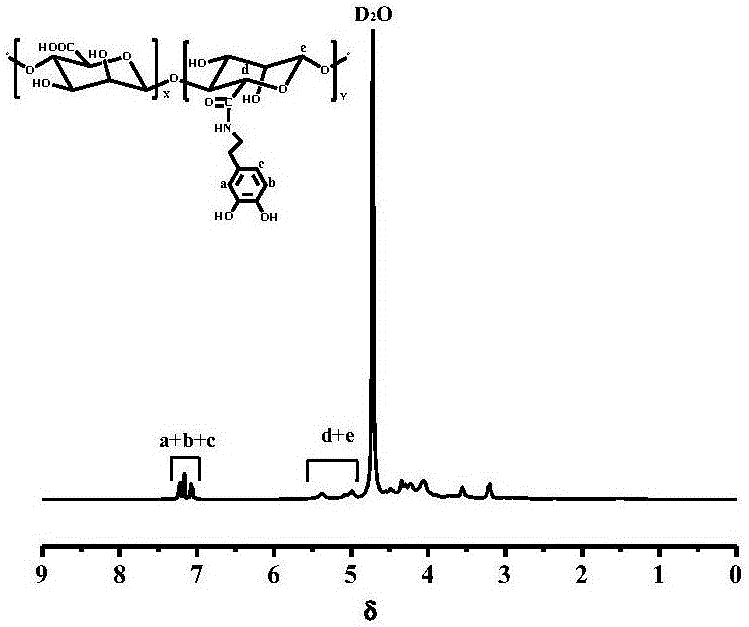

[0015] Embodiment 1, the synthesis of alginic acid-dopamine (Alg-DA) modified macromolecule

[0016] Weigh 1 g of alginic acid (Alg), put it into a three-necked flask, add 100 mL of PBS buffer solution (50 mM, pH=5.5.), stir and dissolve at room temperature, and after it is completely dissolved, add 1.94 g of EDC and 2.32 g of NHS in sequence, n( COOH) / n(EDC) / n(NHS)=1 / 2 / 4, after activation at room temperature for 30 minutes, add 4.79 dopamine hydrochloride (DA), repeat vacuuming and nitrogen three times to exclude air to prevent DA oxidation, under nitrogen atmosphere React at room temperature for 24 hours. After stopping the reaction, dialyze in deionized water to remove the catalyst and unreacted monomers. After there is no dopamine ultraviolet absorption peak in the dialysate, freeze-dry to obtain a white cotton-like biomodified macromolecule Alg-DA.

Embodiment 2

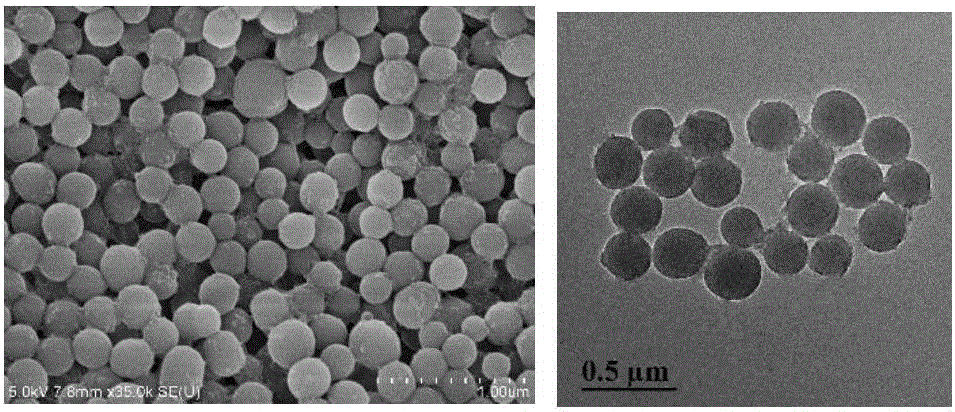

[0017] Embodiment 2, the preparation of polydopamine particle (PDA)

[0018] Add 1.5mL of ammonia water to the mixed solution of ethanol (40mL) and ultrapure water (90mL), stir at 30°C for 30min, then dissolve 0.5g of dopamine in 10mL of ultrapure water and add to the above solution, at 30°C The reaction was carried out for 24 hours, and the obtained product was dialyzed and freeze-dried to obtain PDA particles.

Embodiment 3

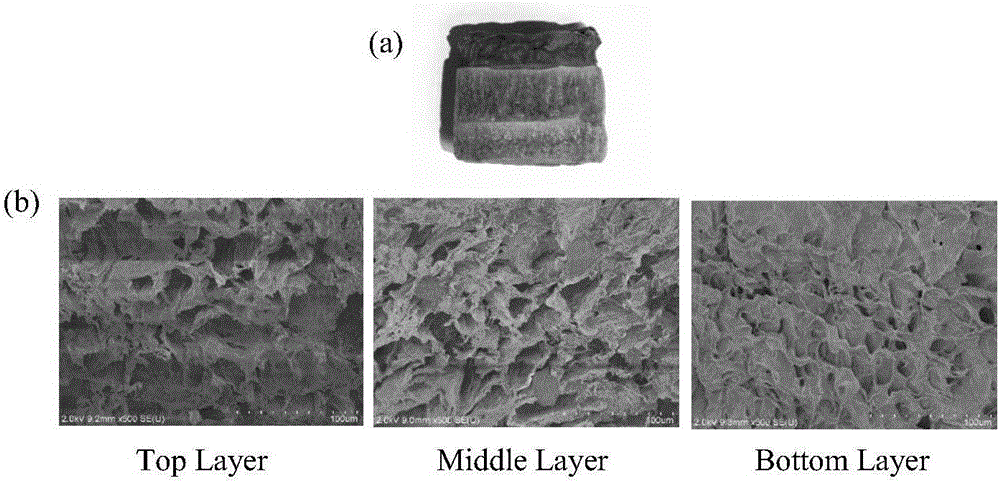

[0019] Embodiment 3, preparation of dopamine-based gradient functional material

[0020] Alg-DA was dissolved in phosphate buffered saline (PBS) with a pH of 5.5 to prepare Alg-DA solutions with concentrations of 2%, 3% and 4%, respectively, and 20 mg of PDA particles were added to the above solutions, and mechanically stirred for 4 hours. First, 2mL of Alg-DA / PDA particles with a concentration of 4% were evenly added to the mold and quickly frozen with liquid nitrogen, and then 2mL of Alg-DA / PDA particles with a concentration of 3% were evenly poured on the first layer of frozen materials And freeze quickly, and finally add 2mL of Alg-DA / PDA particles with a concentration of 2% to the second layer of frozen material. After the third layer of solution is frozen, take out the material and put it in a freeze dryer to freeze dry , the lyophilized material was treated with 5% CaCl 2 Cross-linking is carried out, and the cross-linked sample is washed with ultrapure water and freez...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com