Dental implant and preparation method thereof

A dental implant and implant technology, applied in the fields of prosthesis, medical science, tissue regeneration, etc., can solve the problems of unsatisfactory implantation success rate and long-term repair effect, and achieve personalized treatment, good osseointegration ability, The effect of excellent biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a dental implant, comprising the following steps:

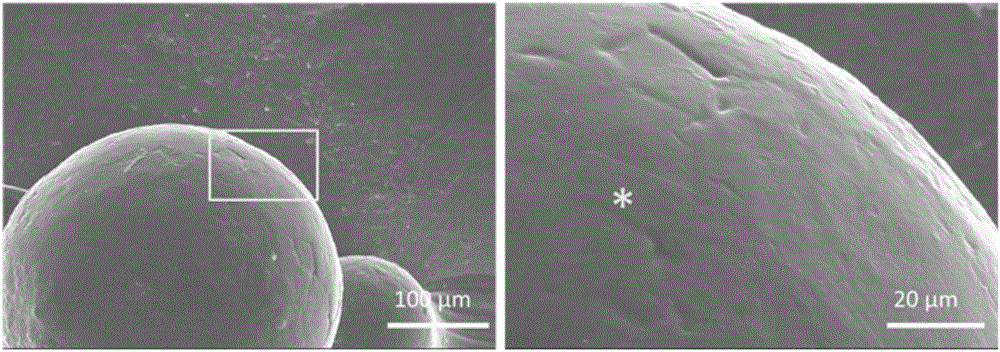

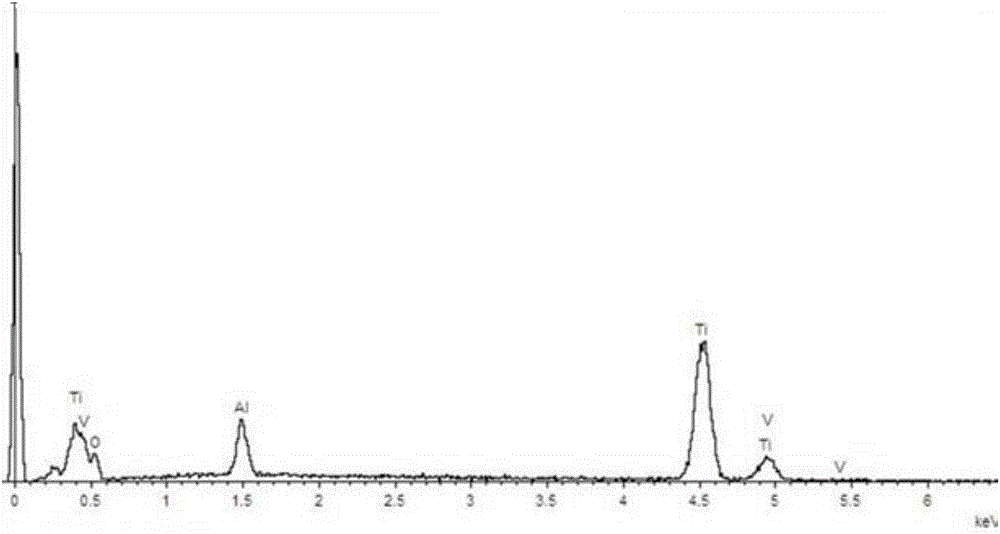

[0032] (1) Use Ti-6Al-4V material to prepare the implant body by 3D printing, use deionized water to continue ultrasonic cleaning until the liquid is clear, and then use acetone, absolute ethanol and deionized water to ultrasonically clean for 15 minutes each, at a constant temperature of 65°C Oven drying for use;

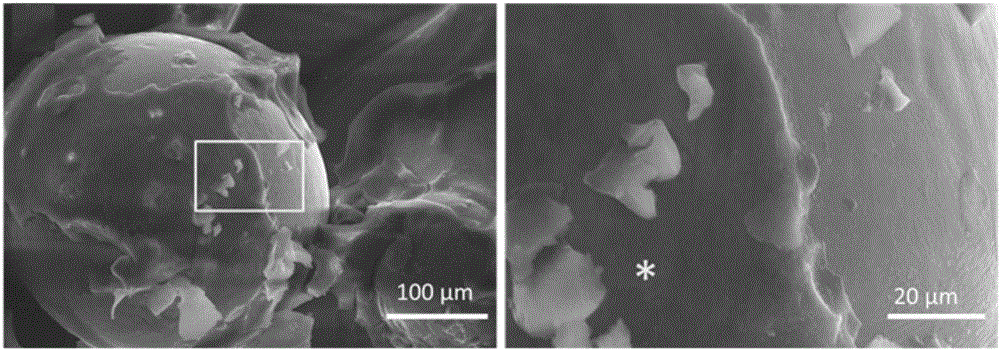

[0033] (2) Soak the implant body in 3% APTES solution for 1 hour to make the surface loaded with positively charged amino groups, and prepare graphene oxide solutions with different concentrations: prepare 0.25 mg / ml graphite oxide with deionized water as solvent alkene aqueous solution;

[0034] (3) Prepare graphene oxide coating on the surface of Ti-6Al-4V sheet by spin coating technology: the specific parameters of spin coating process are: low speed is 600r / min, processing time is 7s, high speed is 1000r / min, processing time 10s, the reaction temperature is room temperature;

...

Embodiment 2

[0038] A method for preparing a dental implant, comprising the following steps:

[0039] (1) Use Ti-6Al-4V material to prepare the implant body by 3D printing, use deionized water to continue ultrasonic cleaning until the liquid is clear, and then use acetone, absolute ethanol and deionized water to ultrasonically clean for 15 minutes each, at a constant temperature of 65°C Oven drying for use;

[0040] (2) Soak the implant body in 3% APTES solution for 1 hour to make the surface loaded with positively charged amino groups, and prepare graphene oxide solutions with different concentrations: prepare 0.5 mg / ml graphite oxide with deionized water as solvent alkene aqueous solution;

[0041] (3) Prepare graphene oxide coating on the surface of Ti-6Al-4V sheet by spin coating technology: the specific parameters of spin coating process are: the low speed is 600r / min, the processing time is 6s, the high speed is 1000r / min, and the processing time is 10s , the reaction temperature i...

Embodiment 3

[0047] A method for preparing a dental implant, comprising the following steps:

[0048] (1) Use Ti-6Al-4V material to prepare the implant body by 3D printing, use deionized water to continue ultrasonic cleaning until the liquid is clear, and then use acetone, absolute ethanol and deionized water to ultrasonically clean for 15 minutes each, at a constant temperature of 65°C Oven drying for use;

[0049] (2) Soak the implant body in 3% APTES solution for 1 hour to make the surface loaded with positively charged amino groups, and prepare graphene oxide solutions with different concentrations: prepare 1.0 mg / ml graphite oxide with deionized water as solvent alkene aqueous solution;

[0050] (3) Prepare graphene oxide coating on the surface of Ti-6Al-4V sheet by spin coating technology: the specific parameters of spin coating process are: the low speed is 600r / min, the processing time is 7s, the high speed is 1000r / min, and the processing time is 10s , the reaction temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com