Carbon dioxide absorbent and method for regenerating carbon dioxide absorbent

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as corrosion of carbon dioxide capture devices, loss of carbon dioxide absorbents, difficulty in capturing carbon dioxide, etc., and achieve excellent carbon dioxide absorption and regeneration Effects of reduction in capacity, viscosity and heat capacity, and reduction in regeneration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

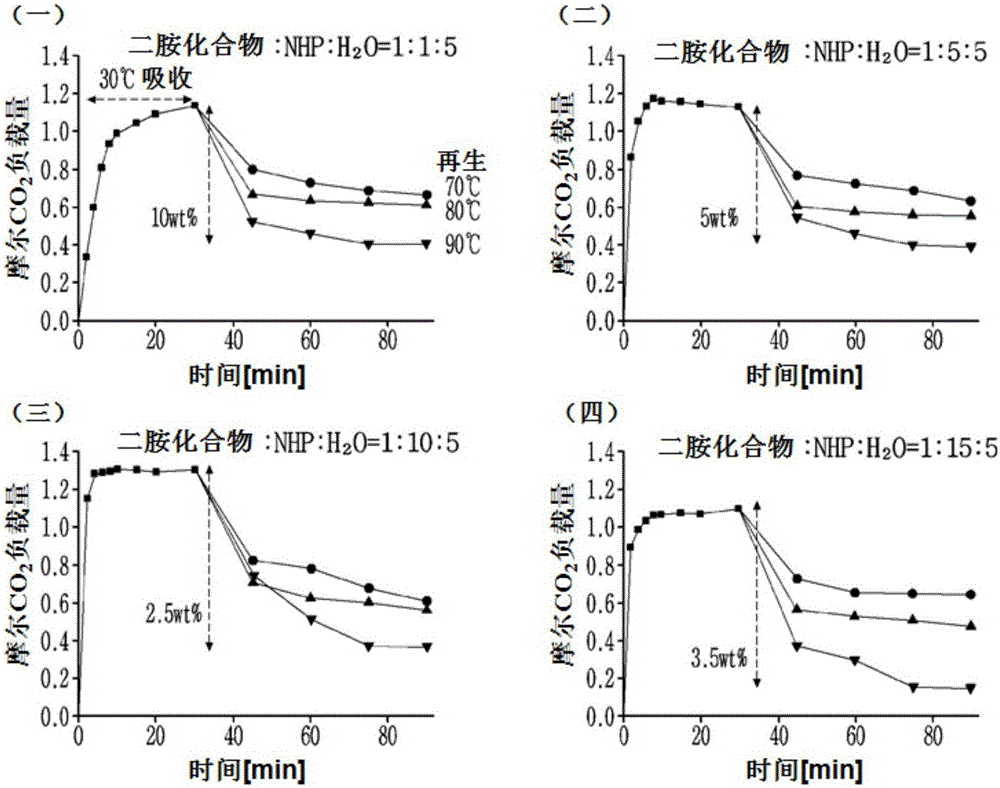

[0078] The carbon dioxide absorption amount and absorption time of the diamine compound, and the regeneration amount and regeneration time of carbon dioxide, which vary according to the concentration of the polar aprotic solvent, were measured.

[0079] Changes in the amount of carbon dioxide absorbed and regenerated were measured while the molar ratio of the diamine compound and the protic solvent was fixed and the molar ratio of the polar aprotic solvent was increased.

[0080] In this case, N,N-diethylpropane-1,3-diamine (N,N-diethylpropane-1,3-diamine) was used as the diamine compound.

[0081] In this case, N-methylpyrrolidone (NMP) was used as the polar aprotic solvent.

[0082] In this case, water was used as the protic solvent.

[0083] At this time, the ratio of the diamine compound, NMP, and water is a molar ratio.

[0084] At this time, 50 ml of carbon dioxide was supplied per minute in the absorption step.

[0085] Absorption of carbon dioxide was carried out at...

experiment example 2

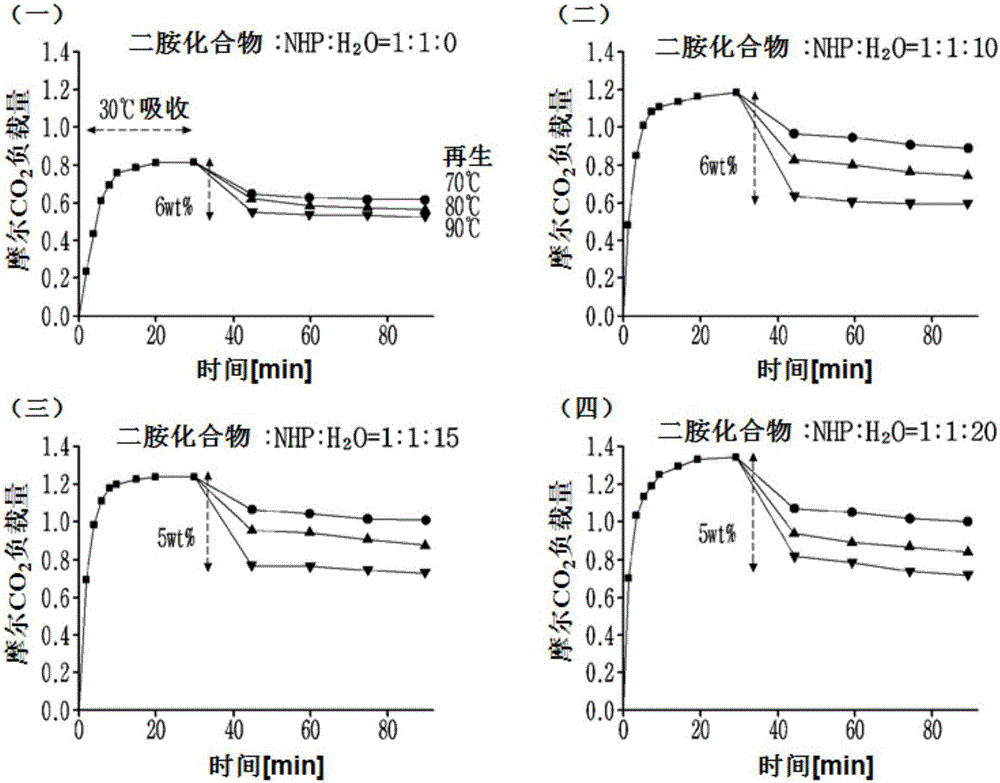

[0092] The carbon dioxide absorption amount and absorption time of the diamine compound and the regeneration amount and regeneration time of carbon dioxide were measured according to the protic solvent concentration.

[0093] Except that under the condition that the molar ratio of the diamine compound and the polar aprotic solvent is fixed and the molar ratio of the protic solvent is increased, changes in the amount of carbon dioxide absorbed and regenerated are measured, and the rest are the same as those in the experiment. The reaction was carried out under the same conditions as Example 1.

[0094] figure 2 It is a graph showing the absorption and regeneration concentration of carbon dioxide according to time measured in Experimental Example 2.

[0095] refer to figure 2 , it can be found that under the carbon dioxide absorption conditions at 30°C and the regeneration conditions of the carbon dioxide absorbent at 90°C, as the content of water as a protic solvent increas...

experiment example 3

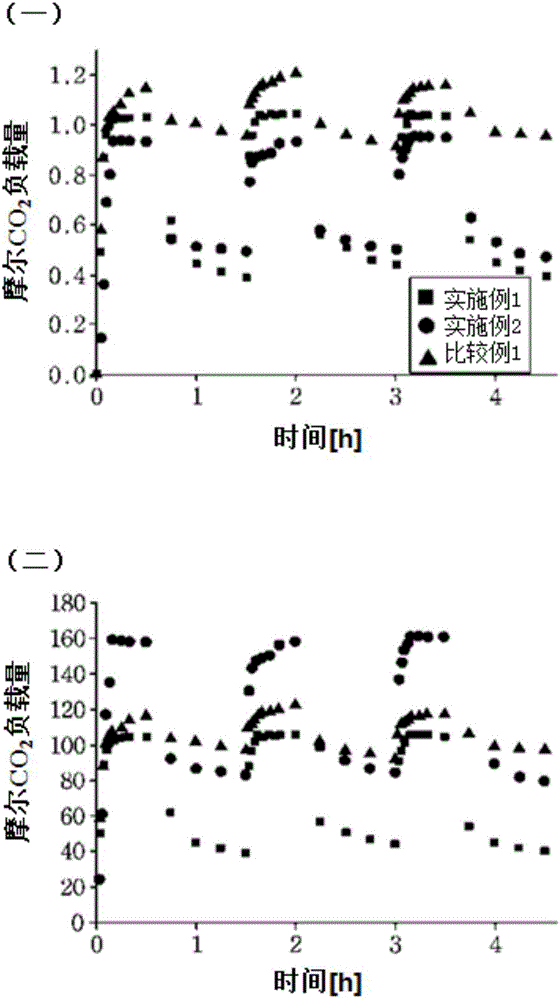

[0099] In Examples 1 and 2 and Comparative Example 1, the absorption amount and absorption time of carbon dioxide of the diamine compound, and the regeneration amount and regeneration time of carbon dioxide were repeatedly measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com