Ore dressing method for copper-sulfur-white tungsten minerals

A beneficiation method and scheelite technology, applied in flotation, solid separation, etc., can solve the problems of large amount of foam flushing water, many times of scheelite flotation flotation, and large medium ore circulation, so as to reduce foam flushing water, The effect of reducing the consumption of harmful ions on the chemical and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

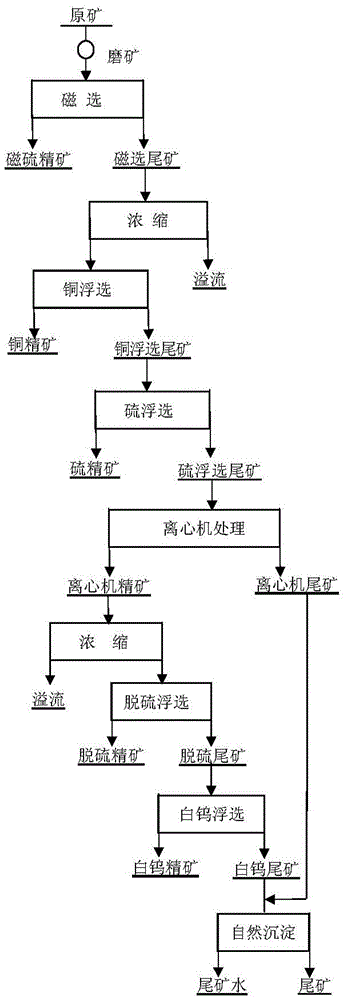

Image

Examples

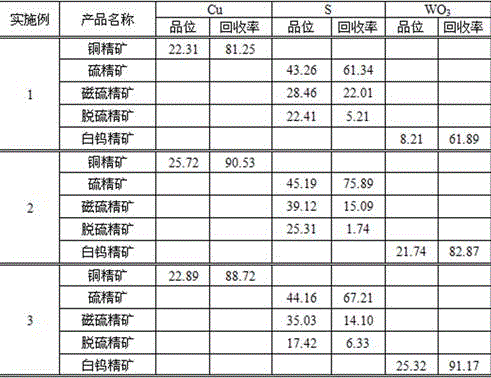

Embodiment 1

[0018] pair containing WO 3 0.08%, Cu 0.16%, S 9.53%, Fe15.76% copper-sulfur scheelite ore. After the raw ore is ground to a grinding fineness of 65%-0.074mm, the following steps are carried out in sequence:

[0019] 1) Magnetic separation: 1 roughing magnetic field strength 0.3T; 1 fine magnetic field strength 0.08T; obtain magnetic sulfur concentrate and magnetic separation tailings;

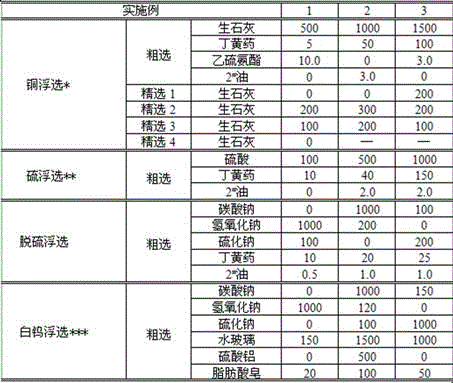

[0020] 2) Copper flotation: Concentrate the magnetic separation tailings to a concentration of 35%, based on the raw ore, 1 roughing: add 500 grams / ton of quicklime, 5 grams / ton of butyl xanthate, and 10.0 grams / ton of thiocarbamate , stirring for 3 minutes; 4 selections: selection 1 and selection 4 do not add quicklime, selection 2 and selection 3 add quicklime 200 and 100 g / ton respectively, and stir for 2 minutes; 1 selection does not add chemicals, Stir for 2 minutes; obtain copper concentrate and copper flotation tailings;

[0021] 3) Sulfur flotation: based on the raw ore, the above-m...

Embodiment 2

[0027] pair containing WO 3 0.21%, Cu 0.67%, S 26.27%, Fe 38.31% copper-sulfur scheelite ore. After the raw ore is ground to a grinding fineness of 74%-0.074mm, the following steps are carried out in sequence:

[0028] 1) Magnetic separation: 1 roughing magnetic field strength 0.4T; 1 fine magnetic field strength 0.15T; obtain magnetic sulfur concentrate and magnetic separation tailings;

[0029] 2) Copper flotation: Concentrate the magnetic separation tailings to a concentration of 30%, based on the original ore, 1 roughing: add quicklime 1000 grams / ton, butyl xanthate 50 grams / ton, 2 # Oil 3.0 g / ton, stirring for 5 minutes; 3 times of selection: selection 1 without quicklime, selection 2 and selection 3 respectively add quicklime 300 and 200 g / ton, stirring for 3 minutes; 2 times of sweeping without adding chemicals , stirring for 4 minutes; obtain copper concentrate and copper flotation tailings;

[0030]3) Sulfur flotation: based on the raw ore, the above-mentioned cop...

Embodiment 3

[0036] pair containing WO 3 1.76%, Cu 0.20%, S 18.94%, Fe27.21% copper-sulfur scheelite ore. After the raw ore is ground to a grinding fineness of 87%-0.074mm, the following steps are carried out in sequence:

[0037] 1) Magnetic separation: 1 roughing magnetic field strength 0.5T; 1 fine magnetic field strength 0.15T; obtain magnetic sulfur concentrate and magnetic separation tailings;

[0038] 2) Copper flotation: Concentrate the magnetic separation tailings to a concentration of 30%, based on the raw ore, 1 roughing: add quicklime 1500 g / ton, butyl xanthate 100 g / ton, thiocarbamate 3.0 g / ton , stirred for 5 minutes; 3 times of selection: 200, 200 and 100 g / t of quicklime were added respectively for selection 1, selection 2 and selection 3, and stirred for 4 minutes; 1 sweep without adding chemicals, stirred for 2 minutes; obtained Copper concentrates and copper flotation tailings;

[0039] 3) Sulfur flotation: based on the raw ore, the above-mentioned copper flotation ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com