An aeration control system and method based on an oxygen consumption rate measuring instrument

A technology for controlling system and oxygen consumption rate, applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Set the desired dissolved oxygen concentration. The set dissolved oxygen value is to make the actual aeration amount as close or consistent as possible to the expected value by changing the aeration amount;

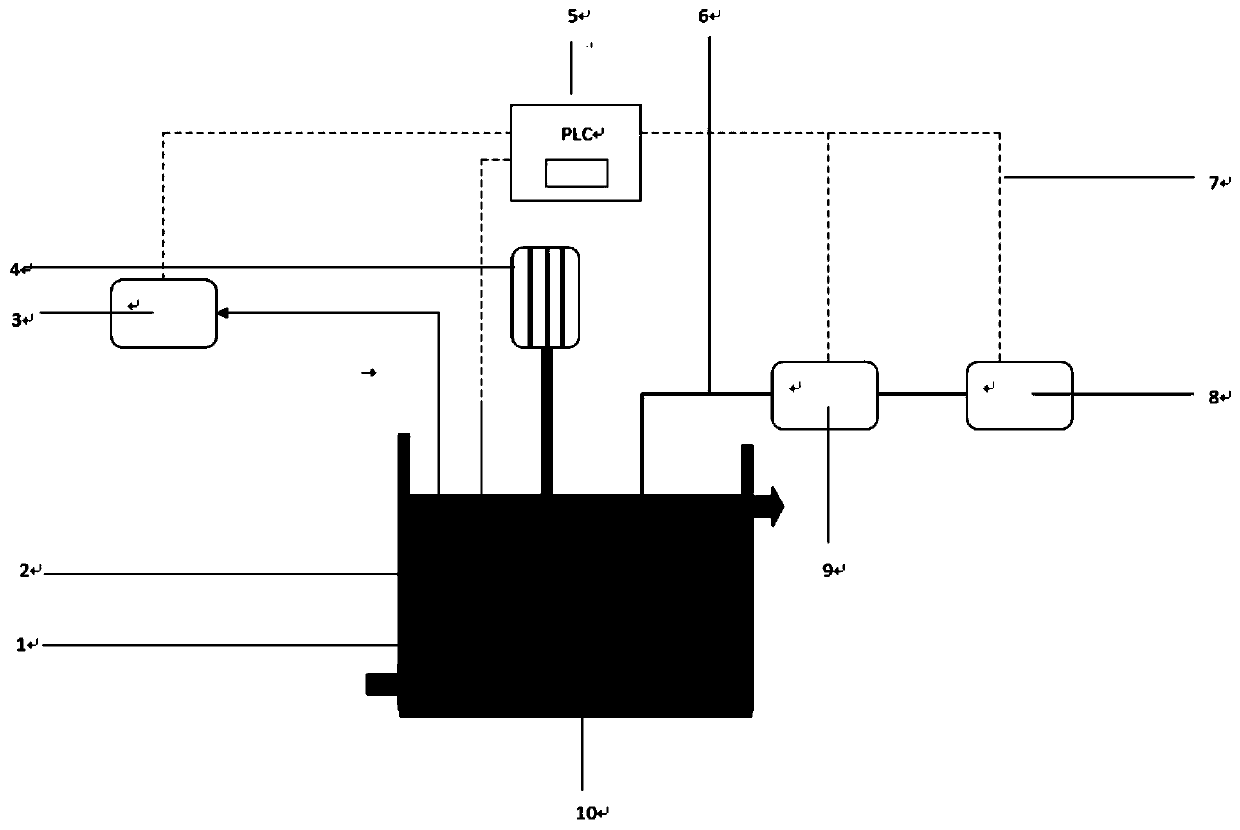

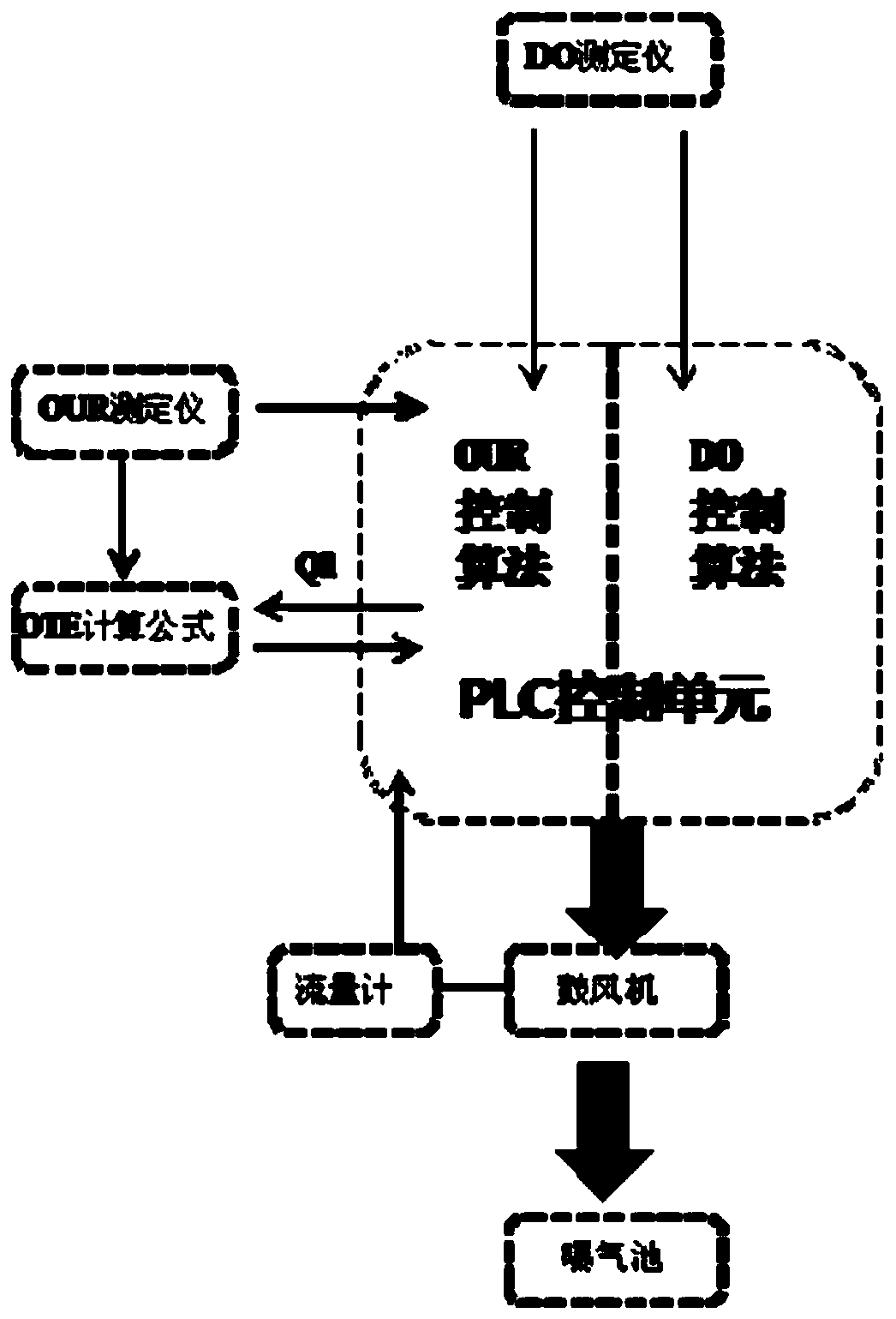

[0089] First write the control algorithm program in the above specification into the PLC control unit 5, when the aeration control system starts to operate, the dissolved oxygen (DO) measuring instrument 2 measures the DO concentration in the sewage in real time, and sends it to the PLC control unit through the data signal transmission line 7 5. The OUR measuring instrument 3 will feed back the data to the PLC control unit 5, and the flow meter 9 will transmit the air volume signal to the PLC control unit 5 in real time through the data signal transmission line 7, and the PLC control unit will calculate the required aeration volume through algorithm integration, and calculate The result is transmitted to the control blower 8 in the form of a signal, and the air volu...

Embodiment 2

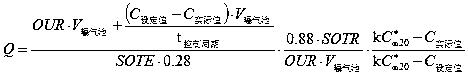

[0094] The volume of the aeration tank is 0.25m 3 , Since the measurement period of the OUR measuring instrument is 15 minutes, the control period is set to 15min, SOTE=20%, SOTR=0.03kg / h, k=0.75, C * ∞20 is the saturated dissolved oxygen value at 20°C;

[0095] The initial setting value of dissolved oxygen is 2. The aeration control can be started after connecting the OUR tester, DO tester and aeration system to the PLC. The OUR tester measures a value every 15 minutes, and the DO tester measures in real time , Each change of the three values of OUR, OTE and DO will be transmitted to the PLC control cabinet through the signal transmission line, and the actual required air volume will be calculated, and the output signal will be sent to the fan to regulate the air volume of the fan. The value of the flowmeter will be displayed through the signal line and recorded on the PLC display.

[0096] Under stable conditions, the OUR and OTE values do not change much, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com