Industrial wastewater treatment system

A technology for treating system and industrial wastewater, applied in metallurgical wastewater treatment, aerobic process treatment, biological water/sewage treatment, etc., can solve the problems of difficult storage of living flocculants, low reuse rate, high production cost, etc. The effect of large-scale promotion and application, saving manpower and material resources, and low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

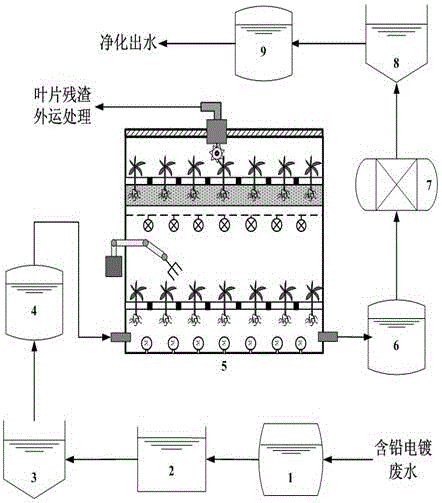

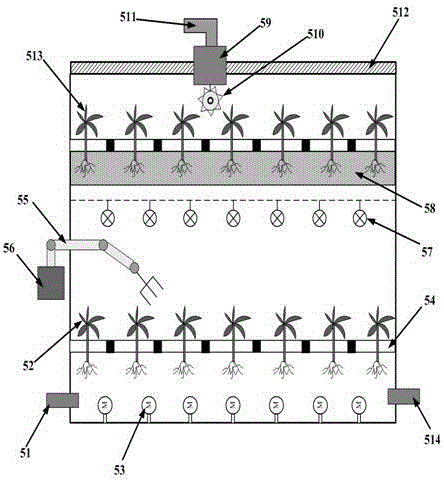

[0028] like figure 1The treatment system for removing lead in electroplating wastewater shown, the system includes 1-collection well, 2-coarse grid, 3-primary sedimentation tank, 4-pH value adjustment tank, 5-plant far-infrared radiation enrichment and removal of lead device, 6-nitration reaction tank, 7-biological denitrification tank, 8-secondary sedimentation tank, 9-water purification tank, etc.; among them, the electroplating wastewater containing lead ions enters the water collection well 1 through the wastewater pipeline, and is collected here And preliminary stable adjustment, the outlet of the collection well 1 is connected to the coarse grid 2 through the wastewater pipeline, where large-diameter solid matter in the wastewater is removed, and the outlet of the coarse grid 2 is connected to the primary sedimentation tank 3 through the wastewater pipeline, where the wastewater is further removed The outlet of the primary sedimentation tank 3 is connected to the pH valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com