Preparation method of in-situ growth silicon carbide nanowire-reinforced porous carbon composite

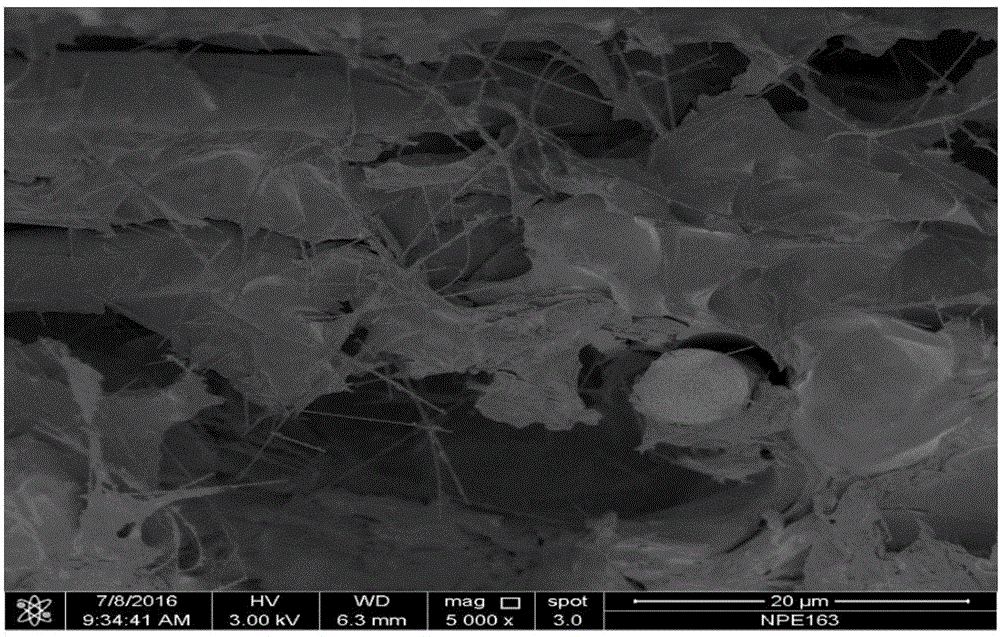

A technology of silicon carbide nanowires and composite materials, applied in ceramic products, applications, household appliances, etc., can solve the problems of easy aggregation of silicon carbide nanowires, damage to the structure of silicon carbide nanowires, and poor dispersion, and achieve large pore diameters , wide application prospects, the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

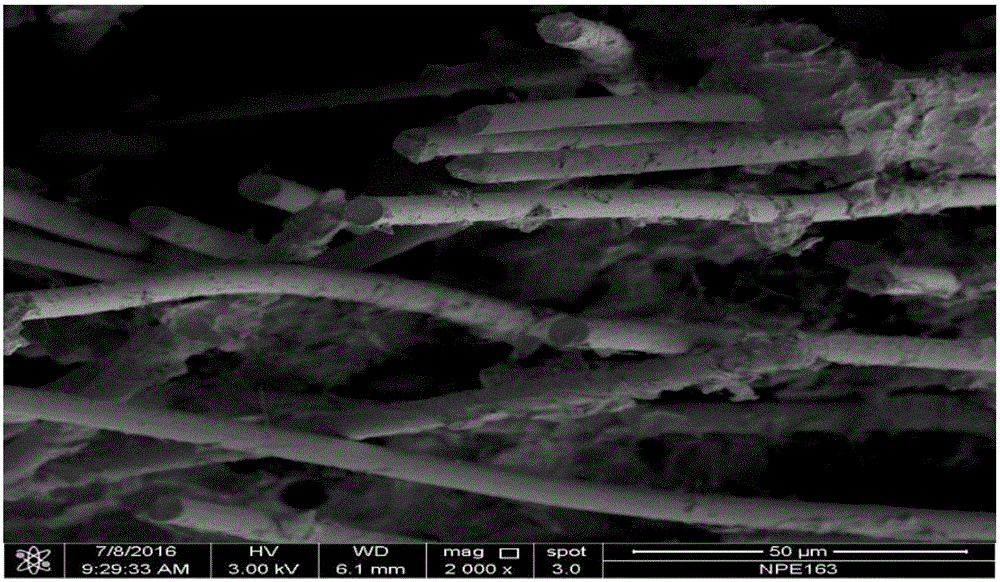

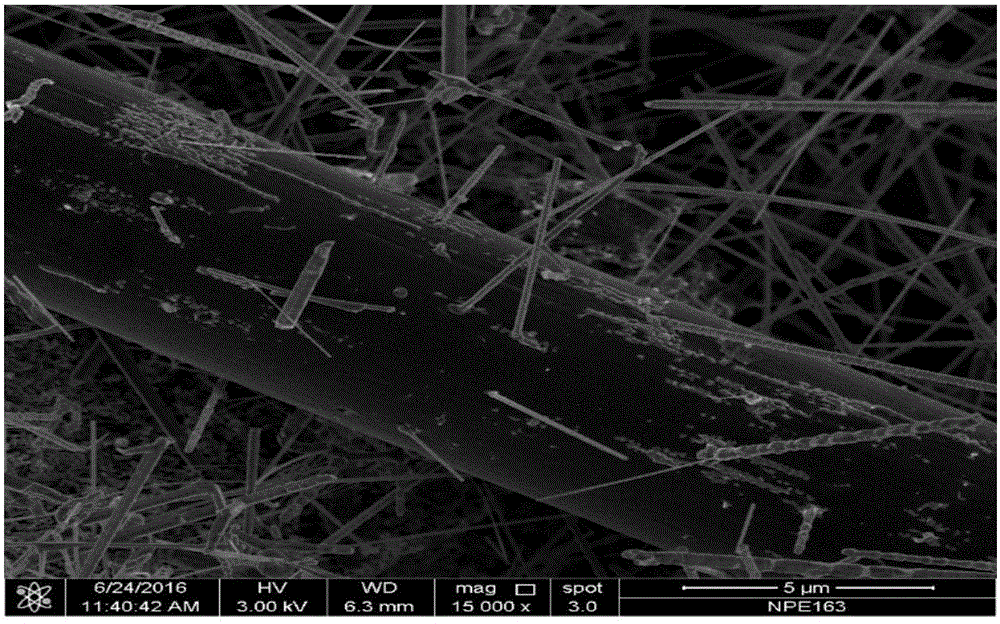

[0019] An in-situ growth silicon carbide nanowire reinforced porous carbon composite material and a preparation method thereof, the steps are as follows:

[0020] (1) Dissolve hydroxyethyl cellulose in distilled water, stir with a magnetic stirrer for 4 hours, and then let stand for 10 hours to form a solution with a concentration of 1.2%.

[0021] (2) Add 3 grams of short carbon fiber (length 3 mm) and 5 grams of phenolic resin particles (0.1 mm in diameter) to the above solution, stir with a magnetic stirrer for 2 hours, and wait for the phenolic resin and short carbon fiber Disperse evenly.

[0022] (3) Pour the dispersed solution into a glass tube, absorb water with a gypsum block at the bottom for 12 hours, and finally form a block of short carbon fibers mixed with resin particles.

[0023] (4) Dry the block in (3), put it into a high-temperature furnace for curing at 200°C for 2 hours, and then carry out carbonization in a high-temperature furnace at 1000°C for 1 hour u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com