Special organic fertilizer for wheat, and preparation method and application method thereof

An organic fertilizer and wheat technology, which is applied in the field of special organic fertilizer for wheat and its preparation, can solve the problems of unreasonable nutrient distribution and short fertilizer effect period, and achieve the effects of reducing fertilization costs, avoiding soil compaction, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

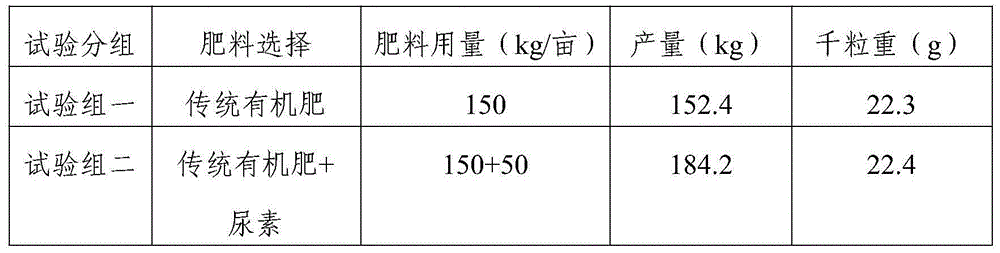

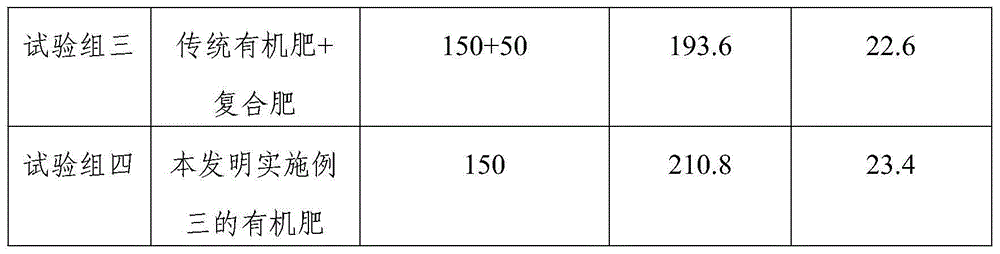

Image

Examples

Embodiment 1

[0024] raw material:

[0025] Vermicompost 10kg, cow dung 100kg, oil 120kg, starter 0.3kg, Eupatorium adenophorum 40kg, moss 20kg, ghost needle grass 20kg, potassium chloride 4kg and potassium nitrate 6kg.

[0026] Preparation:

[0027] (1) Raw material pretreatment: First boil Eupatorium adenophorum, Eupatorium adenophora and moss with water for 20 minutes respectively, then dry Eupatorium adenophorum, Eupatorium adenophorum and moss respectively, grind them and mix them evenly, and The obtained mixed material is sent into a carbonization kiln, the temperature is raised to 120°C and kept at a constant temperature for 3 hours, and then the temperature is raised to 400°C and kept for 8 hours to obtain a semi-carbonized material;

[0028] (2) Fermentation: Send the semi-carbonized material obtained in step (1) and oil dryness, starter, vermicompost and cow dung into the fermentation tank, after stirring and mixing evenly, adjust the moisture content of the fermentation material...

Embodiment 2

[0037] raw material:

[0038] Vermicompost 30kg, cow dung 200kg, oil 180kg, starter 0.4kg, Eupatorium adenophorum 60kg, moss 30kg, ghost needle grass 40kg, potassium chloride 8kg and potassium nitrate 10kg.

[0039] Preparation:

[0040] (1) Raw material pretreatment: first boil Eupatorium adenophorum, Eupatorium adenophora and moss with water for 30 minutes respectively, then dry Eupatorium adenophorum, Eupatorium adenophorum and moss respectively, grind them and mix them evenly, and The obtained mixed material is sent into a carbonization kiln, the temperature is raised to 150°C and kept at a constant temperature for 4 hours, and then the temperature is raised to 500°C and kept for 10 hours to obtain a semi-carbonized material;

[0041] (2) Fermentation: Send the semi-carbonized material obtained in step (1) and oil sour, starter, vermicompost and cow dung into the fermentation tank, after stirring and mixing evenly, adjust the moisture content of the fermentation material ...

Embodiment 3

[0050] raw material:

[0051] 20kg of vermicompost, 150kg of cow dung, 150kg of oil, 0.35kg of starter, 50kg of Eupatorium adenophorum, 25kg of moss, 30kg of ghost needle grass, 6kg of potassium chloride and 8kg of potassium nitrate.

[0052] Preparation:

[0053] (1) Raw material pretreatment: first boil Eupatorium adenophorum, Eupatorium adenophora and moss with water for 25 minutes respectively, then dry Eupatorium adenophorum, Eupatorium adenophorum and moss respectively, grind them and mix them evenly, and The obtained mixed material is sent into a carbonization kiln, the temperature is raised to 130°C and kept at a constant temperature for 3.5 hours, and then the temperature is raised to 450°C and kept for 9 hours to obtain a semi-carbonized material;

[0054] (2) Fermentation: Send the semi-carbonized material obtained in step (1) and oily dryness, starter, vermicompost and cow dung into the fermentation tank, after stirring and mixing evenly, adjust the moisture conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com