Preparing method for high-pressure-resistant tough epoxy paint

A technology of epoxy coating and high pressure resistance, which is applied in the field of coatings. It can solve the problems of epoxy coatings that are not resistant to high temperature, prone to defects in the coating film, and affect the appearance of equipment, and achieve cooking resistance, corrosion resistance, excellent physical and chemical properties, Effect of excellent elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

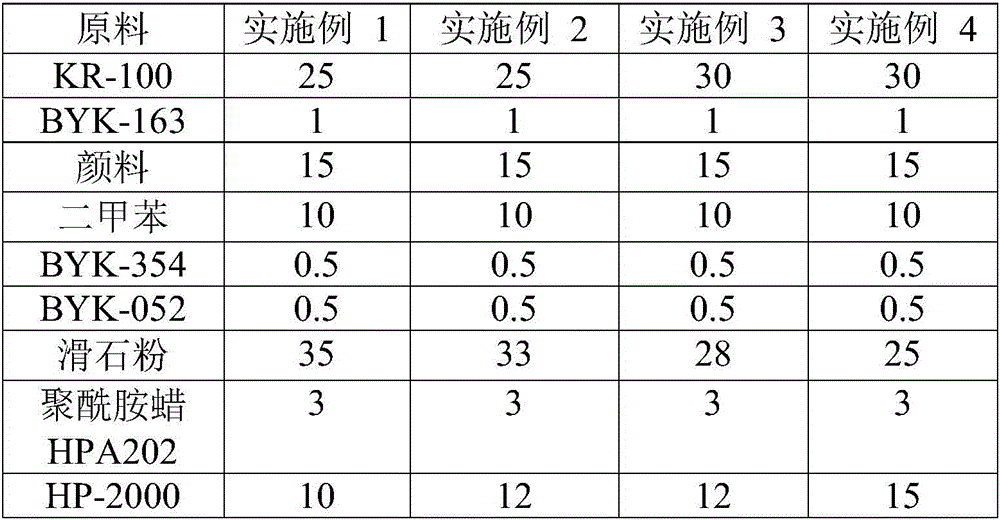

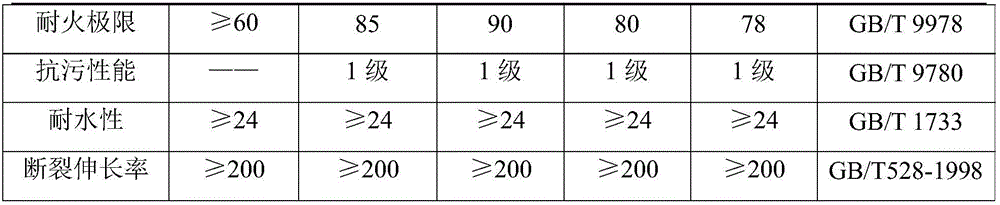

Embodiment 1

[0026] A kind of high-pressure resistant tough epoxy coating, this coating is made of the raw material that comprises following percentage by weight: epoxy resin 25%, pigment 15%, filler 35%, diluent 10%, auxiliary agent 5%, curing agent 10%; The additives include dispersants, leveling agents, defoamers and rheological additives, and the mass ratio of the dispersants, leveling agents, defoamers and rheological additives is 1:0.5:0.5: 3.

[0027] The preparation method of the high-pressure-resistant tough epoxy coating mainly includes the preparation method of the main agent and the preparation method of the curing agent, and the preparation method of the main agent includes the following steps:

[0028] (1) add epoxy resin, diluent, dispersant in the mixer successively, stir under the stirring speed of rotating speed 800rpm;

[0029] (2) Add pigments and defoamers to the mixer in step (1) successively, after fully stirring evenly, add filler, and obtain grinding slurry after ...

Embodiment 2

[0033] A kind of high pressure resistant tough epoxy coating, this coating is made of the raw material that comprises following percentage by weight: epoxy resin 25%, pigment 15%, filler 33%, diluent 10%, auxiliary agent 5%, curing agent 12%; The additives include dispersants, leveling agents, defoamers and rheological additives, and the mass ratio of the dispersants, leveling agents, defoamers and rheological additives is 1:0.5:0.5: 3.

[0034] The preparation method of the high-pressure-resistant tough epoxy coating mainly includes the preparation method of the main agent and the preparation method of the curing agent, and the preparation method of the main agent includes the following steps:

[0035] (1) add epoxy resin, diluent, dispersant in the mixer successively, stir under the stirring speed of rotating speed 800rpm;

[0036] (2) Add pigment and defoamer to the mixer in step (1) successively, after fully stirring evenly, add filler, and obtain grinding slurry after be...

Embodiment 4

[0047] A kind of high-pressure resistant tough epoxy coating, this coating is made of the raw material that comprises following percentage by weight: 30% of epoxy resin, 15% of pigment, 25% of filler, 10% of diluent, 5% of auxiliary agent, 15% of curing agent; The additives include dispersants, leveling agents, defoamers and rheological additives, and the mass ratio of the dispersants, leveling agents, defoamers and rheological additives is 1:0.5:0.5: 3.

[0048] The preparation method of the high-pressure-resistant tough epoxy coating mainly includes the preparation method of the main agent and the preparation method of the curing agent, and the preparation method of the main agent includes the following steps:

[0049] (1) add epoxy resin, diluent, dispersant in the mixer successively, stir under the stirring speed of rotating speed 800rpm;

[0050] (2) Add pigment and defoamer to the mixer in step (1) successively, after fully stirring evenly, add filler, and obtain grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com