Water-based black and transparent wax polishing leather surface finishing agent with color transfer resistance and preparation method of leather surface finishing agent

A technology of surface treatment agent and color migration, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve problems such as difficult to achieve environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

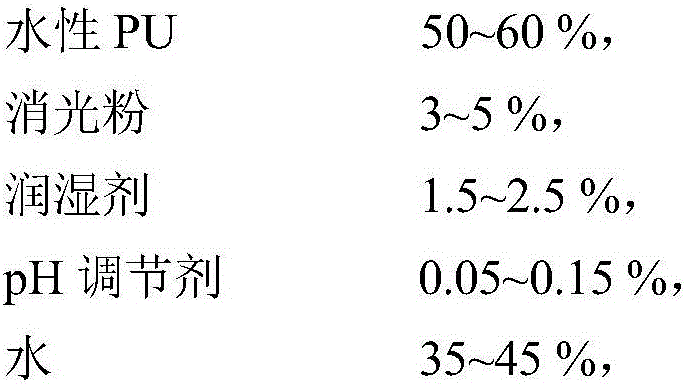

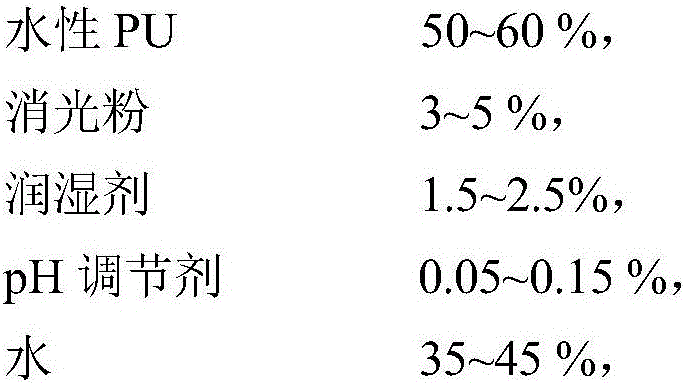

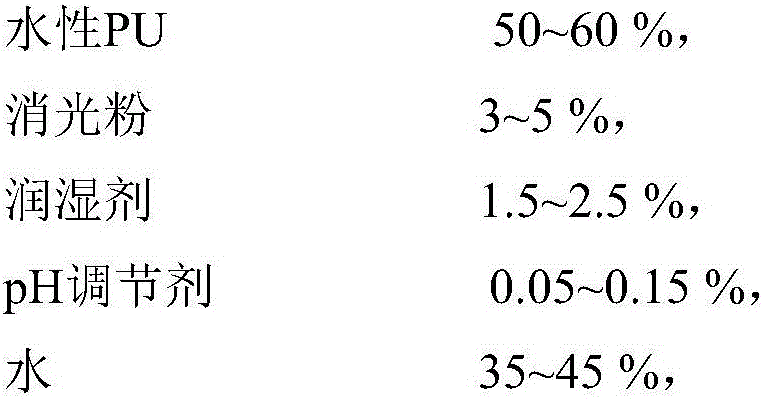

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of water-based PU: 100 g of weighed polyols (20% of polyethylene adipate diol, 20% of polyoxypropylene diol, 60% of reactive polyurethane colorant, and It is black, and the coloring agent that all the other embodiments are used is black) adds in the four-necked flask, starts agitator, stirs. Add 33.3 g of weighed isocyanate (toluene diisocyanate 100%) into the reactor, and add 8 drops of catalyst (100% stannous octoate). Install a thermometer, heat up to 80-85°C, and react within this temperature range for 1.5 hours. Then add 6.9 g of chain extender (50% of ethylene glycol and 50% of dimethylol propionic acid) into the four-necked flask, and continue to react at this temperature for 2 hours. After reaching the reaction time, the reaction temperature was lowered to 65° C., and the nitrogen flow rate was appropriately reduced. Then add 5 g of co-solvent (acetone 100%) to the reactor several times in small amounts to adjust the viscosity of the system. A...

Embodiment 2

[0043](1) Preparation of water-based PU: Add 100 g of weighed polyols (20% of polytetrahydrofuran ether glycol, 20% of polyoxypropylene glycol, and 60% of reactive polyurethane colorant) into a four-necked flask, and start stirring device for stirring. Add 33.3 g of weighed isocyanate (toluene diisocyanate 100%) into the reactor, and add 8 drops of catalyst (100% stannous octoate). Install a thermometer, heat up to 80-85°C, and react within this temperature range for 1.5 hours. Then add 6.9 g of chain extender (50% of 1,4-butanediol and 50% of dihydroxy half ester) into the four-necked flask, and continue to react at this temperature for 2 hours. After reaching the reaction time, the reaction temperature was lowered to 65° C., and the nitrogen flow rate was appropriately reduced. Then in the reactor, a total of 5 g (100% of acetone) of co-solvent was added several times in small amounts to adjust the viscosity of the system. After stirring evenly, slowly dropwise add 5 g of...

Embodiment 3

[0046] (1) Preparation of water-based PU: Add 100 g of weighed polyols (15% of polycaprolactone diol, 25% of polybutadiene diol, 60% of reactive polyurethane colorant) into a four-necked flask, Start the mixer and stir. Add 33.3 g of weighed isocyanate (50% of toluene diisocyanate and 50% of isophorone diisocyanate) into the reactor, and add 8 drops of catalyst (100% of organic bismuth). Install a thermometer, heat up to 80-85°C, and react within this temperature range for 1.5 hours. Then add 6.9 g of chain extender (50% of ethylene glycol and 50% of dimethylol propionic acid) into the four-necked flask, and continue to react at this temperature for 2 hours. After reaching the reaction time, the reaction temperature was lowered to 65° C., and the nitrogen flow rate was appropriately reduced. Then in the reactor, a total of 5 g of co-solvent (100% methyl ethyl ketone) was added several times in small amounts to adjust the viscosity of the system. After stirring evenly, slowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com