Method for hydroprocessing of renewable raw materials

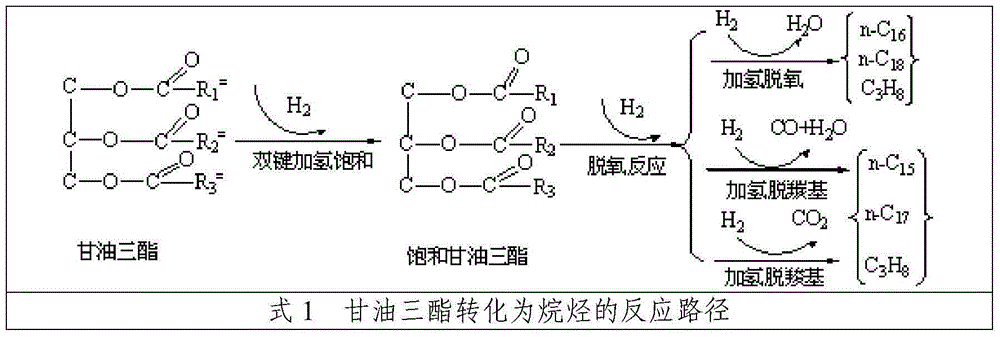

A technology of hydrogenation treatment and regeneration of raw materials, which is applied in the direction of biofuel, fatty acid hydrogenation, fuel, etc., can solve the problems of uncontrollable ratio and high hydrogen consumption, and achieve the effect of reducing hydrogen consumption and improving freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

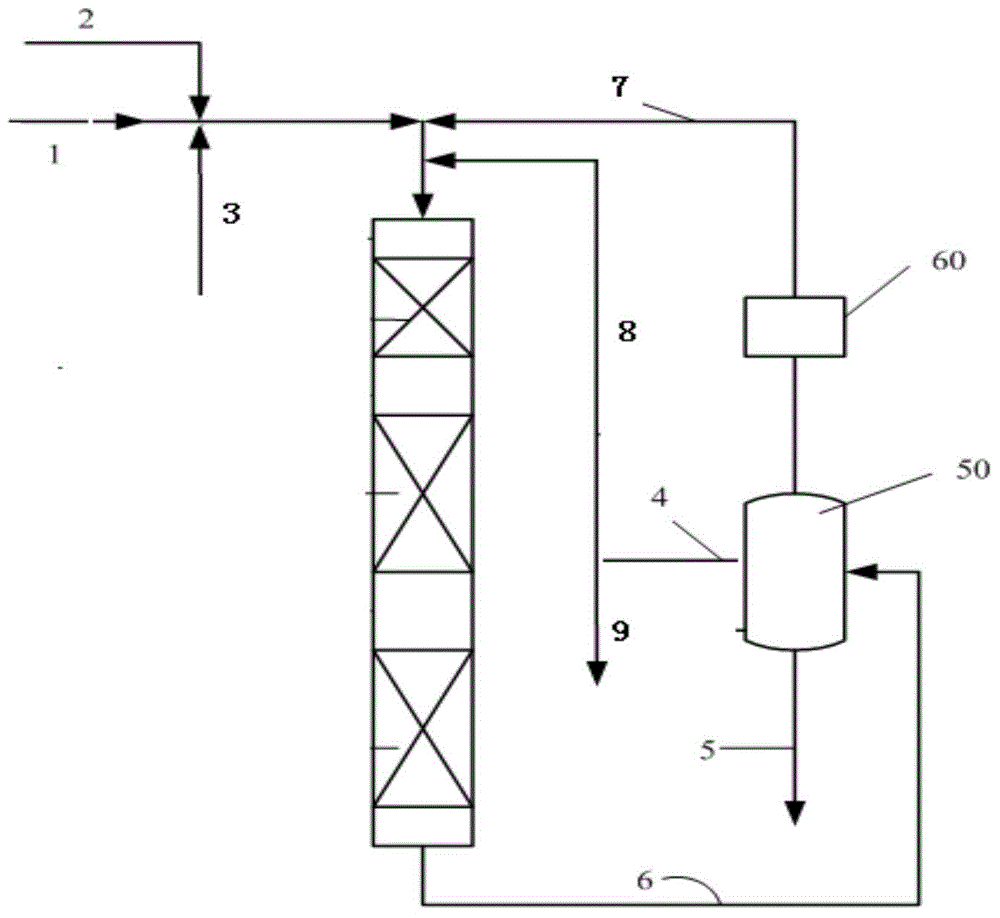

Method used

Image

Examples

Embodiment 1

[0037] The raw material oil is palm oil, and its properties are shown in Table 1. Using the method provided by the invention, after palm oil is fully mixed with hydrogen and water, it enters the hydroprocessing reactor and reacts with the hydroprocessing catalyst in the sulfide state to obtain the hydroprocessing reaction product. Wherein, based on palm oil, the mass content of water entering the hydroprocessing reactor is 8%. Before the palm oil enters the hydroprocessing reactor, dimethyl disulfide is mixed. The concentration is 0.1% by weight. After the hydroprocessing reaction product is separated from gas and liquid, part of its liquid phase hydrocarbon products is recycled back to the inlet of the hydroprocessing reactor, and the remaining part is led out of the device.

[0038] The hydrogenation reaction conditions are shown in Table 2, and the product distribution and properties are shown in Table 3.

Embodiment 2

[0040] Algae oil is used as the raw material oil, and its properties are shown in Table 1. Using the method provided by the invention, after the waste catering oil is fully mixed with hydrogen and water, it enters the hydrotreating reactor and reacts with the hydrotreating catalyst in the sulfide state to obtain hydrotreating reaction product. Wherein, based on waste catering oil, the mass content of water entering the hydroprocessing reactor is 7%. As a standard, the sulfur concentration is 0.1% by weight. After the hydroprocessing reaction product is separated from gas and liquid, part of its liquid phase hydrocarbon products is recycled back to the inlet of the hydroprocessing reactor, and the remaining part is led out of the device.

[0041] The hydrogenation reaction conditions are shown in Table 2, and the product distribution and properties are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com