A processing technology of oil pipeline

A processing technology, oil pipeline technology, applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problem of metal ions not being effectively supplemented, uneven thickness distribution of electroplating layer, uneven current distribution, etc. problem, to achieve the effect of not easy to conduct electricity, not easy to change color, and wide range of current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

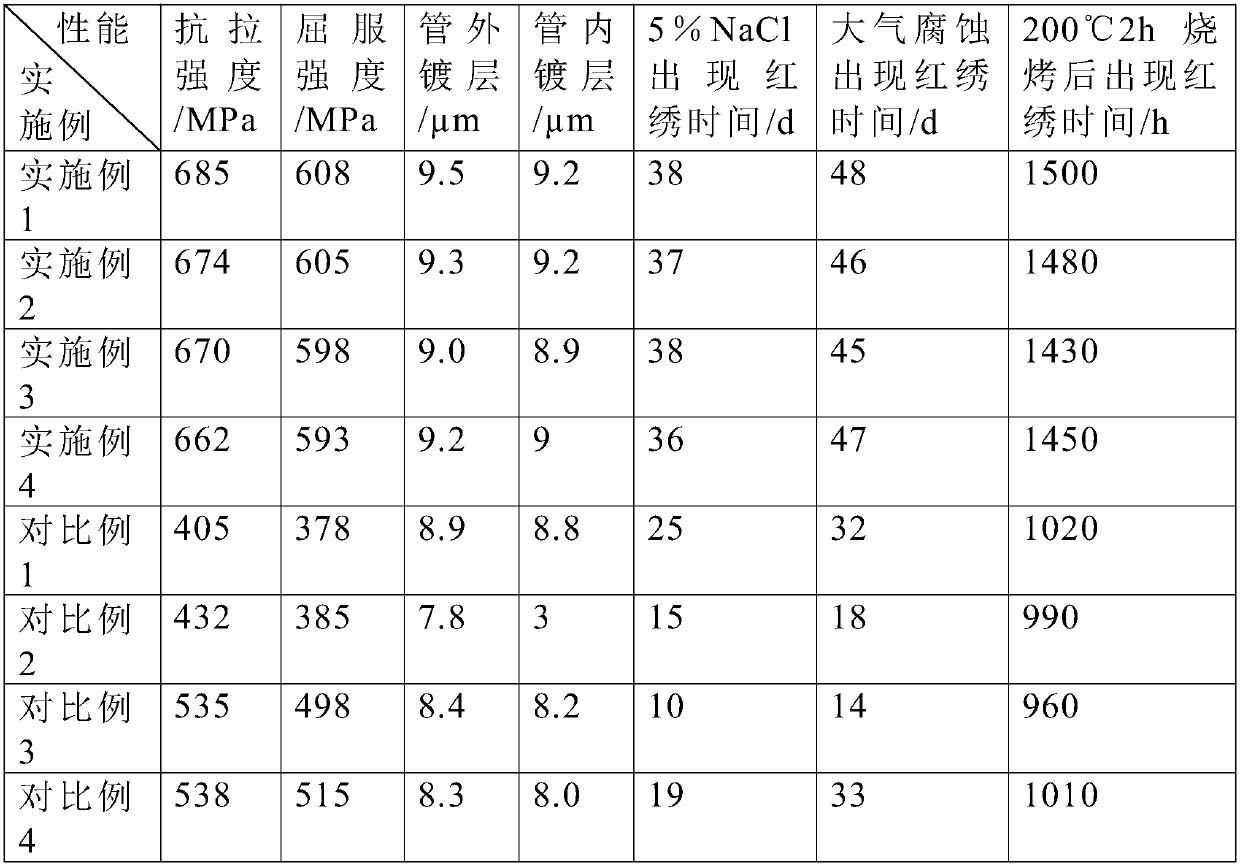

Examples

Embodiment 1

[0033] The alloy steel is processed and formed to obtain the oil pipeline blank; the composition elements and mass percentages of the alloy steel are: C: 0.15%, Cr: 1.4%, Si: 0.18%, Mn: 0.95%, Al: 0.04 %, N: 0.012%, Ti: 0.15%, P≤0.015%, S≤0.018%, and the balance is Fe and unavoidable impurities.

[0034] The oil pipeline blank is electroplated in a zinc-nickel electroplating solution at 25°C by an auxiliary anodic plating process; the composition of the electroplating solution is: zinc oxide 6g / L, sodium hydroxide: 120g / L, nickel: 0.8g / L , Additives: 220ml; wherein, in the auxiliary anode plating process, an external anode is arranged outside the oil pipeline blank, a porous plastic mesh is arranged inside the oil pipeline blank, and an auxiliary anode is arranged inside the porous plastic mesh, and the auxiliary anode is connected with the external anode by a wire; The auxiliary anode plating is carried out in three stages: the first stage, the current density is 4.3A / dm 2 ,...

Embodiment 2

[0038] The alloy steel is processed and formed to obtain the oil pipeline blank; the composition elements and mass percentages of the alloy steel are: C: 0.16%, Cr: 1.38%, Si: 0.22%, Mn: 1.08%, Al: 0.042 %, N: 0.001%, Ti: 0.18%, P≤0.015%, S≤0.018%, and the balance is Fe and unavoidable impurities.

[0039] The oil pipeline blank is electroplated in a zinc-nickel electroplating solution at 28°C by an auxiliary anodic plating process; the composition of the electroplating solution is: zinc oxide 6g / L, sodium hydroxide: 125g / L, nickel: 0.7g / L , Additive: 280ml; Among them, in the auxiliary anode plating process, an external anode is arranged outside the oil pipeline blank, a porous plastic mesh is arranged inside the oil pipeline blank, and an auxiliary anode is arranged inside the porous plastic mesh, and the auxiliary anode is connected with the external anode by a wire; The auxiliary anode plating is carried out in three stages: the first stage, the current density is 4.4A / dm ...

Embodiment 3

[0043] The alloy steel is processed and formed to obtain the oil pipeline blank; the composition elements and mass percentages of the alloy steel are: C: 0.12%, Cr: 1.5%, Si: 0.15%, Mn: 1.15%, Al: 0.03 %, N: 0.008%, Ti: 0.22%, P≤0.015%, S≤0.018%, and the balance is Fe and unavoidable impurities.

[0044] The oil pipeline blank is electroplated in a zinc-nickel electroplating solution at 30°C by an auxiliary anodic plating process; the composition of the electroplating solution is: zinc oxide 7g / L, sodium hydroxide: 130g / L, nickel: 1g / L, Additive: 300ml; wherein, in the auxiliary anodic plating process, an external anode is provided outside the oil pipeline blank, a porous plastic mesh is arranged inside the oil pipeline blank, and an auxiliary anode is arranged inside the porous plastic mesh, and the auxiliary anode is connected with the external anode by a wire; The auxiliary anodic plating is carried out in three stages: the first stage, the current density is 4.5A / dm 2 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com