Construction method for earth pressure balance shield tunneling machine to laterally penetrate through initially-supporting mined tunnel at close range

An earth pressure balance, shield tunneling technology, applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problems of deformation, broken piles, ground subsidence, etc. , to avoid the effect of digging and collapsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

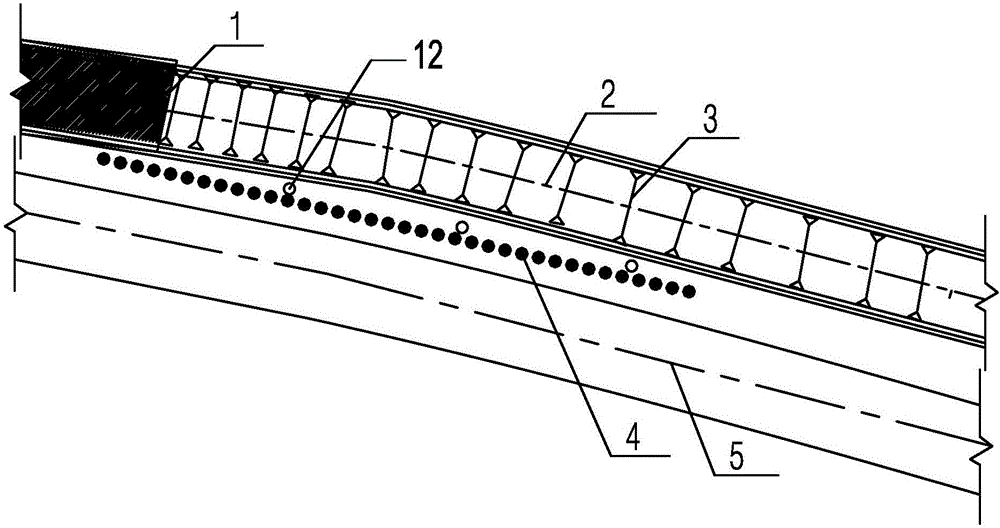

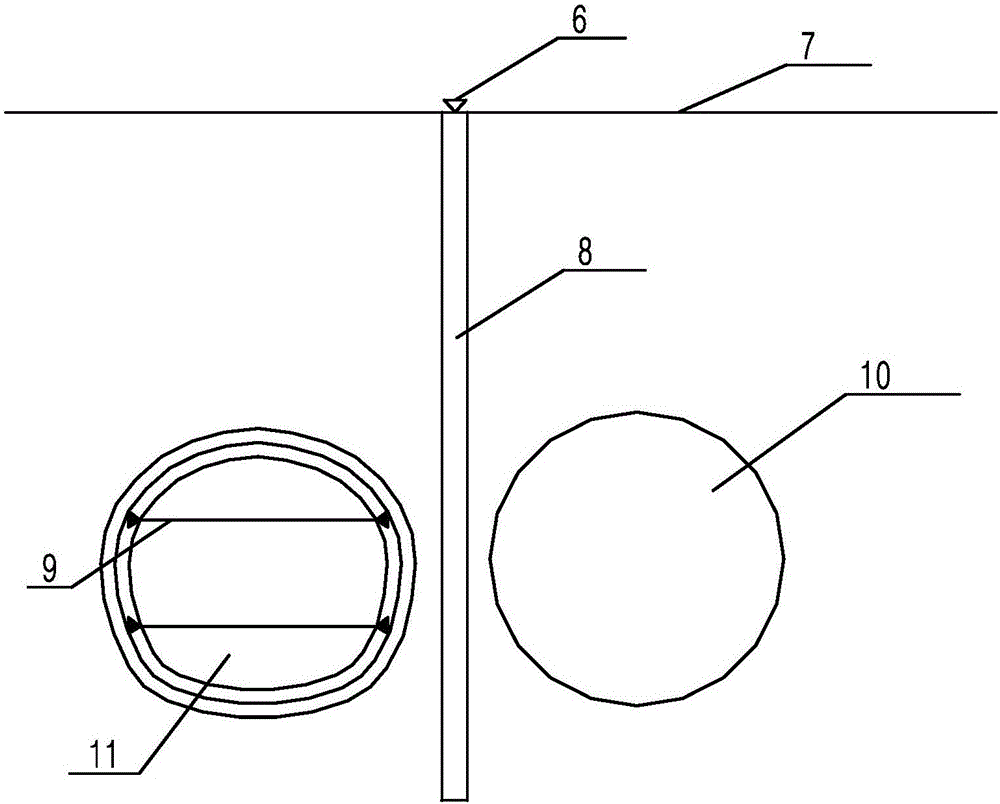

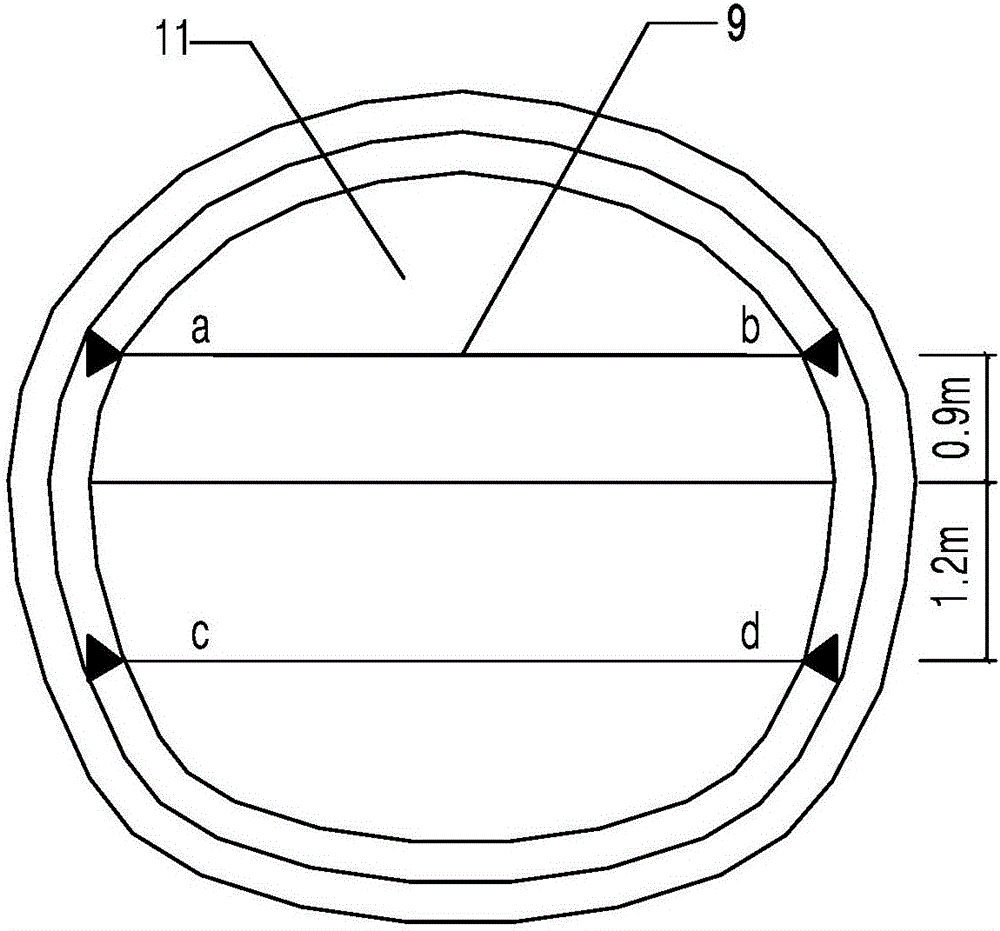

[0030] The embodiment is based on the section of the entry and exit line marked in Phase 2 Civil Construction Construction 03 of Zhengzhou Rail Transit Line 1 as the specific construction site. This section is a mining method tunnel section with a length of 331.221m. The first 100 rings in the section from Xuesong Road Station to Xiliuhu Station first pass through the reinforcement area of Duantou Well. The horizontal clear distance between the excavated tunnel of the entrance and exit line and the adjacent section (71.425m) of the right line of the Xue-xi section is 2.73m-4.00m, and the buried depth of the underground excavated tunnel in the adjacent section is 9.79-9.31m, and the corresponding right line The buried depth of the shield tunnel is 9.97-11.31m. The bidding section is close to Xiliu Lake, with high water level and strong fluidity, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com